FASTECH’s FastMax: A Big Splash in Transportable Hydrogen Fueling

January 15, 2026I’ve been riding the hydrogen wave for years, and I have to say, FastMax is making some serious waves in transportable hydrogen fueling. This isn’t a laboratory pipe dream—it’s a fully functional mobile hydrogen station you can hitch to your fleet and start pumping fuel wherever you need. Imagine the freedom to take your refueling site right to the action, no permanent build-outs required. It’s cutting capital costs and chopping the red tape that usually comes with building a permanent site. Honestly, it feels like the hydrogen industry’s long-awaited pivot.

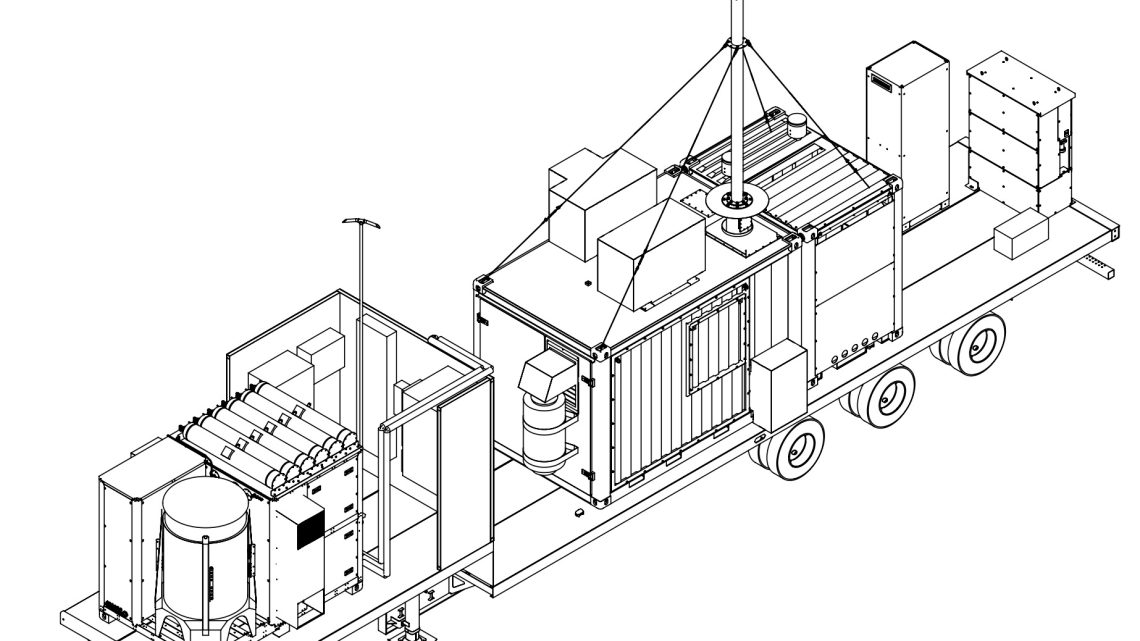

The Transportable Game-Changer

When FASTECH rolled out the FastMax Mobile Fueling System, they weren’t kidding around. This trailer-mounted marvel is a self-contained hydrogen station: it pulls up to your fleet’s door, plugs in (often just a basic power hookup), and voilà—350-bar or 700-bar fueling on demand. Light trucks or massive haulers, it’s all covered without digging up your yard for permanent infrastructure. Production teams are lining up these rigs as we speak, and in a few months, you could see fleets across the country testing them out. They’re built to handle the rigors of the road, too—shock-absorbing, weather-resistant, and ready for action in hot, cold, or downright extreme conditions. The system’s in final assembly, ready to hit the road and make transportable hydrogen fueling a reality.

How It Works—Simple Yet Sophisticated

At the heart of this GH2 fueling system are high-performance compressors from Maximator. These German powerhouses crank the pressure in onboard vessels, so you can do high-flow fills right off the trailer. No bulky extras, no fuss—just hook up your power source, park the unit, and you’re pouring hydrogen into tanks. The control software is cloud-enabled, so you can monitor pressure, track fills, and schedule maintenance from your office. There’s even remote troubleshooting, so if something hiccups, the support team can jump in without sending a technician on a red-eye flight. It’s a true turn-key experience: a couple of hours to set up and you’re fueling fleets like you’ve had a fixed station on site for years.

Why FastMax Matters Now

Look, California’s set the gold standard for cutting emissions. The California Air Resources Board has been all in on zero-emission trucking, and over at the Port of Long Beach, projects like the Shell HDV station—built by FASTECH—are already changing the game. But here’s the kicker: fleets won’t buy fuel cell rigs without fuel stations, and nobody builds stations without vehicles on the road. FastMax nukes that chicken-and-egg problem by bringing the station straight to the fleet. No upfront site work. Just roll up and refuel. Beyond ports, logistics parks and distribution yards are under pressure to meet strict emissions caps, and FastMax could be the ace up their sleeve. By offering flexible hydrogen infrastructure, operators can test new routes without a million-dollar station deal hanging over their heads.

Built for the Future

Heavy-duty trucking is a massive emissions hotspot, and manufacturers like Toyota are pushing out prototype fuel cell trucks for long-haul routes. Those rigs need rock-solid, high-pressure fills to keep ‘em rolling. FastMax delivers consistent 350- and 700-bar options that meet today’s specs. Sure, liquid hydrogen setups can hit sky-high flows (8–10 kg/min), but they come with cryo tanks and crazy site demands. FastMax’s gaseous approach keeps it nimble—perfect for fleets dipping their toes in hydrogen or operating where fixed stations are years away. Plus, with hydrogen prices expected to drop as electrolyzer capacity scales up, fleets that lock in now could see operating costs decline over time, giving them a competitive edge in the long haul.

Complementary, Not Competing

Some people wonder, “Why hassle with a GH2 fueling system trailer when liquid stations exist?” Here’s the lowdown: LH2 hubs rock for heavy traffic, but they need cryogenic storage, specialized pumps, and millions in setup. FastMax, by contrast, slides into your operation with minimal groundwork. It’s modular—start with one unit, see where usage lands, then tack on more trailers as your fleet grows. It’s almost like renting a station instead of buying a house. And for those already running LH2 hubs, FastMax trailers can bridge gaps during maintenance downtime or peak demand, ensuring zero interruptions in service.

Hydrogen’s Long Road to Maturity

When I first started covering hydrogen stations a decade ago, California had maybe a handful—pilot projects tucked away in labs or at isolated fueling islands. Fleets wouldn’t invest in fuel cell trucks because there were no stations; investors wouldn’t bankroll stations without trucks on the road. Then heavy hitters like Shell, Iwatani, and Toyota jumped in, and CARB began funding freight decarbonization at Long Beach and beyond. Over the years, suppliers like NEL Hydrogen refined their modules—compressors, storage, dispensers, you name it—to be more plug-and-play. But the footprint and cost stayed hefty. I remember talking to a fleet manager back then who joked that getting hydrogen was like chasing unicorns. We’ve come a long way since then, but the trophy at the end of the hunt is finally within reach. FastMax is the next leap: a trailer you tow in, fill up, and roll out—no permanent site needed unless you want one.

Partnerships Power Progress

No one does this solo. FASTECH teamed up with Maximator for world-class compressors and NEL Hydrogen for proven station modules. Throw in experience from Iwatani Corporation of America and Shell Renewables and Energy Solutions, and you’ve got real-world know-how on CARB regulations, soil remediation at Long Beach, and utility hookups. Between engineering sprints, regulatory puzzles, and real-world testing, these partnerships have been the glue holding this project together. It’s a textbook example of industry collaboration driving innovation forward—and it shows FASTECH is in it for the long haul, pushing forward hydrogen infrastructure that actually works.

Standards and Integration

FastMax isn’t flying blind—it’s built around standards like SAE J2601-5, which sets the rules for high-flow LH2 fueling in medium and heavy-duty applications. While the GH2 fueling system doesn’t hit LH2’s 18 kg/min pipes, it follows the 350/700-bar curves spelled out in gaseous protocols. It also plays nicely with emerging telematics and fleet management platforms, meaning you don’t have to rip out your existing systems to get started. That means you can plug FastMax into your fleet today without waiting on fresh certifications—totally future-proof.

Collateral Impacts: Democratizing Access

Here’s where it gets exciting: by turning a fixed station into a portable asset, FASTECH is unlocking hydrogen for everyone from city buses and waste management trucks to airport shuttles and private fleets. No need for a multi-million-dollar build—just lease or buy a trailer. That slims down costs and gets more players into the zero-emission race. And as demand picks up, operators can stack FastMax units like LEGO blocks to crank up capacity, even in areas without hydrogen pipelines or onsite production. Think about small towns, rural routes, or disaster zones where fuel infrastructure is scarce. FastMax could be the go-to resource in emergencies or during large-scale events, keeping essential services running when it matters most.

Economic and Environmental Edge

FastMax’s ripple effects could spark whole new industries: trailer assembly lines, maintenance services, operator training, safety certifications—you name it. Plus, loading more hydrogen into heavy-duty trucks means dialing back diesel, slashing CO₂, and cleaning up air quality around busy roads and ports. As the green economy expands, communities around ports, highways, and logistics hubs stand to benefit from healthier residents and a livelier local job market—giving sustainability a face that goes beyond abstract numbers. It’s a classic win-win: more jobs, cleaner communities, and a clear route to decarbonize one of transportation’s toughest segments.

As FastMax rolls into final assembly, I’m itching to see its first real-world gigs. Will it become the go-to for a big retailer handling overflow traffic? Or maybe a logistics hub testing a small hydrogen fleet at an inland terminal? Could a city use one as an emergency backup for events or disaster response? Imagine cross-border corridors where a fleet can roll from one state or province to another, fueling up at a mobile hydrogen station along the way. Or think about pop-up stations at major events, conventions, or remote worksites—FastMax has the flexibility to make it happen. The possibilities are practically endless.

Bottom line… FastMax shows that hydrogen infrastructure can be rolled out fast, scaled on demand, and flex with your needs. This milestone lights the way to the decarbonized future we’ve been dreaming about. It’s that kind of nimbleness that tells me FASTECH isn’t just building gear; they’re building momentum for the hydrogen infrastructure revolution. Keep an eye on FastMax—it’s ready to roll.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.