Gas-Atomized Ca-Mg Eutectic Powders for On-Demand H₂

January 20, 2026A Room-Temperature Hydrogen Generation Leap

Picture this: you need a quick dose of hydrogen for a portable fuel cell—no bulky electrolyzer, no high-pressure tanks. A research team has whipped up gas-atomized Ca-Mg eutectic alloy powders that do exactly that. Drop 1 g of powder into 100 mL of water at 25 °C and voilà—you’ll see 737–760 mL of H₂ bubble up in just ten minutes. Crank the water to 60 °C and you’re squeezing out about 835 mL of H₂ per gram. Best part? No catalysts, no extra energy inputs—just powder meeting water. This is a game changer for on-the-fly hydrogen production and portable hydrogen storage.

How It Works

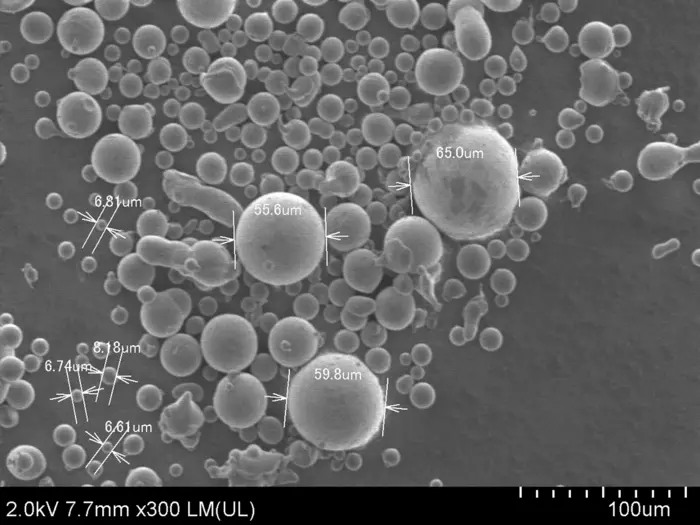

The trick is all in the powder’s microstructure. Gas atomization crafts spherical particles (6–65 µm across) with barely any surface oxidation and a nanoscale dispersion of Ca-rich and Mg₂Ca phases. That fine mix keeps water pathways short so the hydrolysis reaction doesn’t stall under a passivation layer. In plain English, most of the alloy converts cleanly into metal hydroxides and H₂, letting you tap into efficient sustainable energy without a hitch.

Historical Context

Using metal-water reactions for hydrogen production isn’t exactly new. Pure calcium flakes deliver solid yields but can be a handful to handle. Magnesium hydride (MgH₂) is a bit safer but often chokes under a dense Mg(OH)₂ film. Aluminum alloys—remember MIT’s 2021 gallium-indium coating trick—relied on grain-size tweaks to push performance. The beauty of the Ca-Mg eutectic approach is how it marries alloy chemistry with industrial-scale gas atomization. The result? A sweet spot of high output, room-temp operation, and scalable manufacture that aligns perfectly with today’s push for zero-emission technology.

Technical Dive

Zoom in with SEM and TEM and each particle looks like a miniature landscape: tiny Ca-rich islands dotting an Mg₂Ca matrix. That patchwork breaks up any continuous hydroxide barrier, allowing a self-sustaining hydrolysis front to sweep through the powder. No rare catalysts, no exotic coatings—just smart microstructuring doing the heavy lifting for efficient energy release. By refining the microstructure, this design optimizes hydrogen production at the materials level—something that could pave the way for more robust hydrogen infrastructure down the line.

Potential Applications

- Emergency power units—on-demand H₂ for fuel cells when the grid goes down

- Portable hydrogen supply devices for remote operations or field labs

- Backup power in telecom, medical, and defense sectors seeking zero-emission technology

- Stationary micro-generation units in off-grid scenarios, boosting distributed sustainable energy access

Business and Strategic Angle

While this powder isn’t a product on store shelves yet, the concept could flip how we think about hydrogen infrastructure. Instead of trucking around compressed gas or running giant electrolyzers, you’d ship dry powder and water. That could simplify logistics, tighten up safety protocols, and even nudge regulators to rewrite the rulebook. Of course, real-world adoption hinges on cost models, large-scale production safety, and figuring out what to do with all those hydroxide byproducts.

Collateral Impacts and Challenges

The upside’s huge: more distributed energy access, less dependency on centralized H₂ plants, and greener emergency power. But there are still hurdles to clear:

- Manufacturing scale-up: Gas atomization at multi-ton volumes demands rock-solid safety standards.

- Water source: Freshwater isn’t always on hand—researchers are gearing up to test seawater compatibility next.

- Byproduct handling: Calcium hydroxide and magnesium hydroxide need disposal or value-added uses.

- Long-term stability: How will the powder hold up after months or years on the shelf? That’s still an open question.

Future Directions

- Assess hydrogen yield and reaction kinetics in seawater.

- Study powder stability over extended storage periods.

- Build comprehensive safety and cost models for industrial-scale production.

What to Watch

If these powders can be made safely at scale and perform under real-world conditions, they could redefine portable hydrogen generation. Keep an eye on pilot projects in off-grid telecoms or emergency response later this year. And don’t be surprised if “just add water” H₂ cartridges start popping up in the market a few years down the road.

Reported Jan. 1, 2026.

source: sciencedirect.com

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.