Geologic Hydrogen Production Advances Through Element One’s Partnership with Stone to H2

February 20, 2026Announcing the Partnership

Just recently, Element One Hydrogen & Critical Minerals Corp. and Stone to H2, Inc. inked a definitive option and earn-in deal to roll out advanced Geologic Hydrogen Production and Critical Minerals Extraction tech. It’s a savvy move that dovetails perfectly with the global push for greener energy and rock-solid supply chains for the metals we rely on in renewable technologies. Under the agreement, Element One Hydrogen will gradually earn rights to Stone to H2’s subsurface hydrogen and solution-mining methods through staged investments and share issuances. As Timothy Johnson, COO of Element One, puts it, ‘This deal puts us right at the forefront of geologic hydrogen innovation and technology.’

By tapping into North American subsurface know-how, the two companies are setting up a one-two punch: producing natural hydrogen while pulling out the key metals—lithium, nickel, cobalt and friends—that fuel battery manufacturing and other green tech applications. At the helm for Stone to H2, Dr. Gadikota brings decades of hands-on research in underground reactions, ensuring lab breakthroughs actually work at scale in the field. Together, these teams will pilot the technology at strategic sites before moving to full commercial rollouts, potentially shaking up both the clean energy and mining worlds.

This arrangement isn’t happening in a vacuum. Across the board, investors are showing more confidence in natural hydrogen pathways—distinct from electrolytic or fossil-based methods. As companies race to stake claims on promising geological formations, partnerships like this one can seriously speed up commercialization and scale-up efforts.

How the Technology Works

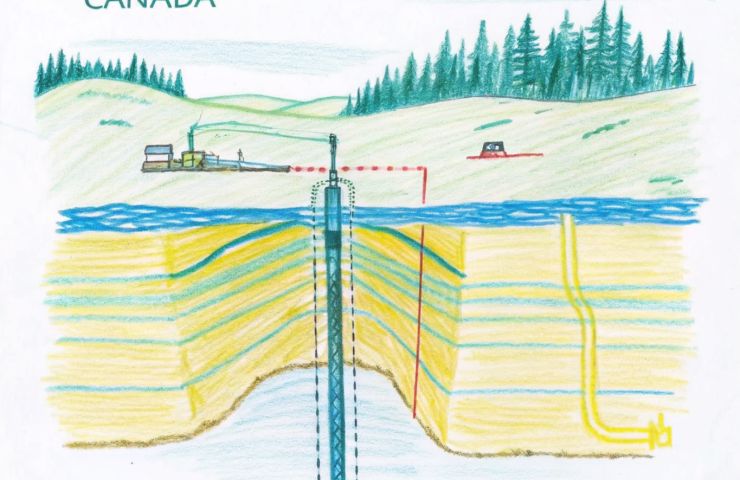

The concept is straightforward but brilliant: send engineered fluids deep underground where they dissolve target minerals and, in the process, free up hydrogen gas. Those gases bubble up alongside a mineral-rich solution, which is then lifted to the surface. There, operators separate out the metals, and the hydrogen is captured, ready to be used as a clean fuel. By combining mining and energy production at the same spot, you avoid drilling separate wells and slash the overall footprint of each operation.

Stone to H2’s secret sauce lies in tight control over fluid chemistry and pressure. By tweaking the mix, temperature and injection rates, engineers can adapt to different rock types and mineral profiles. The setup is fully modular: you can add or reconfigure injection and recovery wells as resources get tapped out or new zones come into play. Down the road, the system can scale up to a commercial level, supplying a steady stream of hydrogen and critical minerals without the environmental baggage of traditional open-pit mining.

Practical Applications & Benefits

This partnership is tackling real-world needs in industries where reliable, clean energy and essential metals are in high demand. Think fertilizer plants, steel mills and chemical refineries—places that can now generate on-site hydrogen without depending on pipelines or high-carbon processes. Meanwhile, battery makers get a local, steady supply of the minerals they need to keep electric vehicles and grid-storage systems humming.

Even more, remote communities stand to gain big. Small towns that struggle with power outages or lack of infrastructure can use on-site hydrogen to fuel microgrids, telecom towers or emergency backup systems—zero-emissions style. And since the tech reuses existing wellbores instead of carving up landscapes, locals benefit from job creation and economic uplift without the disruption of large-scale surface excavation. It’s made in Canada, made for Canada’s future, and it’s a shining example of Clean Energy Technology done right.

Environmental & Economic Impact

Blending resource extraction with emission-free energy generation, this approach shrinks the environmental footprint of two traditionally separate operations. Conventional open-pit mining can scar vast tracts of land, guzzle water and kick up dust, while standard hydrogen production often leans on fossil fuels. By recycling injection fluids and keeping everything underground, the surface impact and water usage drop dramatically. Plus, when the captured hydrogen is used in fuel cells, the only byproduct is water—no greenhouse gases.

On the financial side, the earn-in structure is all about pacing investment with performance. In Year 1, Element One will issue one million common shares and pony up $446,000 for tech development to secure a 10% stake. Year 2 brings two million shares and $1.23 million in funding to lift that to 30%, and Year 3 kicks in three million shares plus $2 million to hit 60%. From there, Element One can climb up to 96% ownership with more cash or shares and up to $10 million in field-trial commitments. It’s a clear, step-by-step path showing they’re in it for the long haul.

Academic Collaboration Strengthens Research

This agreement also bolsters Element One Hydrogen’s ties with top universities, tapping into academic labs to fine-tune the new technologies. By pooling resources, researchers and engineers will dive deep into subsurface reactions, developing cutting-edge monitoring tools for pressure, temperature and chemical composition. The goal? Better well designs, higher recovery rates and rock-solid environmental safeguards.

This kind of industry-academic teamwork is exactly what’s driving breakthroughs in Clean Energy Technology today. Universities gain access to real-world data that supercharges ongoing studies, and companies benefit from fresh insights—and a pipeline of graduates trained on these innovative subsurface systems.

Looking Ahead

With global demand for clean fuel and critical minerals climbing fast, this partnership puts both Element One Hydrogen and Stone to H2 at the forefront of an emerging sector. Field trials are already mapped out at high-potential sites, each with clear success benchmarks. Once those boxes are checked, Stone to H2 will fold in as a subsidiary of Element One, blending niche expertise with the parent company’s broader resources.

Of course, hurdles remain—permits, community buy-in and regulatory hoops to jump through. But by tackling these challenges head-on with a unified approach, the project charts a tangible path toward greener, more resilient industries. Keep an eye on this space—it could very well set the template for future collaborations that unlock natural hydrogen and essential minerals together, reshaping the way we think about resource development and Clean Energy Technology on a global scale.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.