Green Hydrogen Production Catalyst from IIT (ISM) Dhanbad

February 16, 2026Imagine making green hydrogen production way more wallet-friendly—well, that’s exactly what a team at IIT (ISM) Dhanbad has done. They’ve whipped up a budget-friendly catalyst that could bridge the gap between flashy lab demos and real-world electrolysis setups. This breakthrough lines up perfectly with India’s National Green Hydrogen Mission and opens doors for everything from cleaner factories to power solutions in the countryside.

Core Innovation

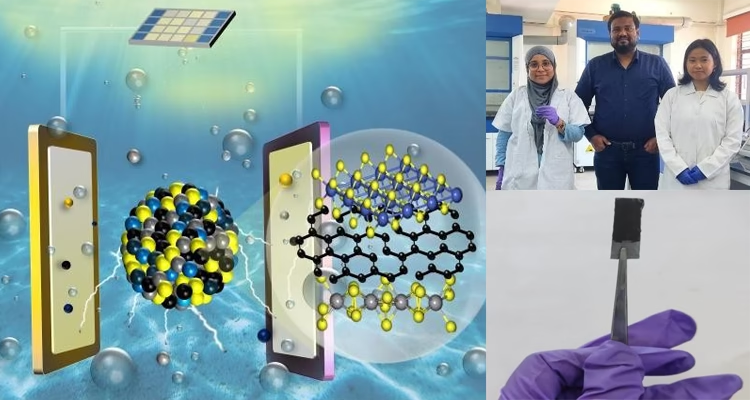

At the heart of this work is an electrode material dreamed up by INSPIRE Faculty member Sk Riyajuddin and his crew. They mixed molybdenum disulfide (MoS2) and vanadium sulfides (VS) into a reduced graphene oxide (rGO) matrix—no pricey platinum or ruthenium needed. Instead, they leaned on good old abundant elements like molybdenum, vanadium, sulfur, and carbon. Their paper in Small shows this combo doesn’t just talk the talk; it brings high electrocatalytic activity while slashing costs.

Technical Insight

Here’s the nitty-gritty: Electrolysis splits water into hydrogen and oxygen using electricity. The rGO acts like a superhighway for electrons, while the metal sulfides serve up active spots for hydrogen evolution. Hook it up to a solar cell—say, a silicon panel—and you get sunlight straight into electric current, which then powers the catalyst to churn out hydrogen. That means fewer energy handoffs and a smoother solar-to-hydrogen ride.

Strategic Partnership for Rural Impact

But the lab isn’t the only stage. IIT (ISM) Dhanbad just signed on with Indian Oil Corporation Limited (IOCL) under a ₹76.42 lakh MoA to dream up a solar hydrogen–driven cooking system for villages. Instead of smoky biomass stoves, households could tap hydrogen from solar electrolysis and store it for cooking—no more indoor smoke, fewer health woes for women and kids, and a big win for rural health.

Why This Matters

- Cost Reduction: Green hydrogen in India now costs between ₹250–₹350/kg. Ditching noble metals could dial down those numbers significantly.

- National Green Hydrogen Mission: India’s eyeing 5 million tonnes of annual green hydrogen by 2030. Cheap catalysts are key to that plan.

- Industrial Decarbonization: Industries—steel, fertilizer, refining—need hydrogen. Affordable green hydrogen can replace grey hydrogen from fossil fuels.

- Solar Integration: Direct solar-to-hydrogen saves you from shaky grids and maximizes your renewable setup.

- Rural Development: Clean hydrogen cookstoves can wipe out indoor air pollution, which kills millions each year.

- Economic Opportunities: Ramp-up in production means new factories, skilled jobs, and export possibilities across Southeast Asia and the Middle East.

Context: From Coal to Clean Energy

Dhanbad’s been known as India’s “Coal Capital” for decades, home to vast reserves and heavy industries. The old Indian School of Mines—today’s IIT (ISM)—started back in 1926, blending academic rigor with energy know-how. But years of coal mining have taken a toll, so the region’s pivoting hard into sustainable energy and hydrogen infrastructure, turning past expertise into a springboard for cleaner futures.

Potential Impacts and Challenges

This catalyst could ripple through society, but it comes with its own hurdles:

- Improve Public Health: Swapping biomass for hydrogen cookstoves could drop respiratory illness rates dramatically.

- Boost Industrial Competitiveness: Cheaper hydrogen feedstock might lure green steel and ammonia projects.

- Promote Technology Transfer: It’s not just tourism—modular electrolyzers and catalyst know-how could jet out to new markets.

- Enhance Energy Independence: Moving away from coal and oil imports slashes geopolitical risks.

- Support Environmental Restoration: Less coal burning and biomass harvesting mean ecosystems get a breather.

Still, some bumps lie ahead:

- Stranded Assets: Coal mines and thermal plants must transition carefully to keep jobs intact.

- Water Demand: Electrolysis is thirsty work—it could compete with agriculture in dry areas.

- Materials Supply: Scaling up rGO production without creating new bottlenecks is no small task.

- Rural Uptake: Financing, upkeep, and changing cooking habits can slow down hydrogen stove adoption.

- Grid Integration: Off-grid hydrogen hubs need solid renewable generation and storage to keep the lights—and stoves—on.

Global Context

All around the world, governments—from the EU’s Hydrogen Strategy to U.S. infrastructure bills—are betting big on hydrogen. With everyone racing to decarbonize industry, a smart, low-cost MoS2–VS–rGO catalyst could give India the edge in the emerging green hydrogen market. Industry watchers often talk about hitting around ₹100/kg for parity with fossil-based hydrogen, though IIT (ISM) hasn’t officially pegged that number yet.

Scientific Validation

Publishing in Small brings some serious street cred, drawing eyes from researchers and investors. Domestic coverage in The Times of India and The Statesman shows people back home are excited, while energy experts highlight this innovation’s role in advancing electrolysis and hydrogen storage conversations.

Scaling Up Research and Commercialization

Turning lab-scale magic into commercial electrolyzers means boosting production by, well, a lot. We’re talking about manufacturing catalysts hundreds of thousands of times beyond research batches. That calls for rock-solid supply chains for molybdenum, vanadium, and graphene, plus standardized processes to keep quality in check. The National Green Hydrogen Mission’s subsidies and low-interest loans will be a lifeline for early adopters.

Long-term stress tests and real-world trials across different climates will fine-tune designs, and partnering with local communities on pilots can shape practical solutions for maintenance and financing in rural settings.

Conclusion

What IIT (ISM) Dhanbad has pulled off is more than just a lab win—it’s a big step toward making hydrogen production more reachable and affordable. By leaning on earth-abundant materials and tapping into renewables, they’re moving India closer to its net-zero dreams and fueling a global push for sustainable energy and industrial decarbonization. With the IOCL collaboration adding a dose of real-world impact, we’re inching toward a future where zero-emission tech powers both factories and family kitchens. If you’re tracking green hydrogen and electrolysis breakthroughs, this catalyst is definitely one to keep on your radar.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.