Humidity-Resistant Hydrogen Sensor Boosts Safety in Clean Energy Systems

February 9, 2026You might’ve heard hydrogen’s the next superstar in clean energy, and for good reason: zero emissions, top-tier storage and versatility for transport, industry and power generation. But it comes with a catch—hydrogen sneaks away at the slightest crack, and if you don’t catch leaks fast, things can get dangerous. That’s where Chalmers University of Technology steps in. Their team has just unveiled a cutting-edge humidity-resistant catalytic plasmonic hydrogen gas sensor designed to nail down even the tiniest escapes in steamy, moisture-heavy environments. It’s a breakthrough aimed squarely at boosting clean energy safety.

Humid challenges: a quick rewind

For as long as anyone can remember, water vapor has been the Achilles’ heel of gas sensors. It clogs up measuring surfaces, masks hydrogen signatures and drags response times to a crawl. Whether you’re talking fuel cells, outdoor stations or buried pipelines, you can’t escape moisture. Past fixes leaned on bulky heaters or air-drying stages—tactics that drove up cost, weight and upkeep. Hardly ideal when you want widespread hydrogen leak detection on the cheap.

Powering safety with a clever twist

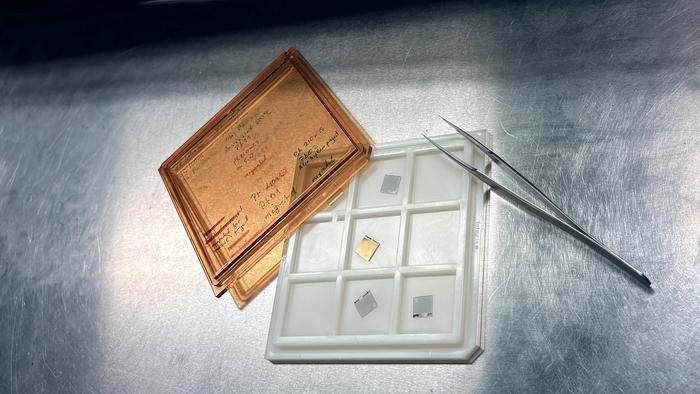

What if humidity wasn’t the enemy but the hero? That’s the spark behind this plasmonic hydrogen sensor. A nano-thin water film sits on platinum nanoparticles. When stray hydrogen arrives, it reacts and heats the platinum, vaporizing that tiny moisture layer. Thanks to plasmonic effects, the sensor reads shifts in color and intensity as the water thins out—signals that actually get stronger with more humidity. In lab tests, it spotted leaks down to 30 parts per million and held steady for over 140 hours.

Real-world leak detection at its finest

Rainy fueling stations, hidden pipelines, blazing-hot factories—this device stays sharp everywhere. By embracing moisture instead of fighting it, the design ditches heaters and dryers. That means fewer bits to break, lower maintenance and zero loss in sensitivity when humidity soars. For operators, it translates to faster alerts, fewer safety shutdowns and a simpler path to airtight hydrogen networks.

Made in Sweden, ready for the world

Designed and tested in Gothenburg, this sensor taps into Sweden’s deep roots in nanofabrication and optical metrology. While full-scale production and commercial tie-ups are still lining up, local assembly is primed to spark new jobs in the nation’s advanced manufacturing and clean-tech sectors. It’s a home-grown solution with a global game plan.

Tapping into Chalmers research excellence

This project builds on decades of Chalmers research prowess in plasmonic sensing. Led by Professor Christoph Langhammer and doctoral researcher Athanasios Theodoridis, the team just published its findings in ACS Sensors. Industry watchers—especially those crafting hydrogen hubs and power plants—are already circling for a closer look.

From lab nerdiness to field readiness

Moving from a polished prototype to a plug-and-play gadget takes a few more steps. Next up: packing the sensor into a compact module with built-in optical readers and wireless connectivity, so you can check leak levels from your phone or laptop. They’re also testing hybrid materials to ramp up speed and robustness against extreme conditions. No official rollout date yet, but pilot installs at Swedish industrial sites are on the horizon.

Stretching across sectors and geographies

This sensor isn’t fussy. From maritime bunkering stations to off-grid microgrids and hydrogen-blended pipelines, it fits right in. Picture a solar electrolyzer up north where cold and moisture team up to challenge electronics. You still need rock-solid readings. This compact, low-maintenance marvel could become the go-to choice wherever water vapor and Mother Nature play a role.

Driving down costs for wider adoption

Safety gear often drives up project budgets. By scrapping pre-dryers and hefty heaters, this humidity-resistant hydrogen sensor could seriously slice sensor costs and cut back on upkeep. The team estimates production on standard microfabrication lines could keep unit prices on par with conventional gas detectors—opening the door for every hydrogen facility to add reliable leak detectors without breaking the bank.

Fueling the next generation of experts

More than just a lab project, it’s a hands-on training ground for Chalmers students in nanotech, optical engineering and energy systems. Workshops and internships with regional firms are already in motion, giving students real-world sensor-building chops and feeding local employers’ talent needs. It’s a virtuous cycle: fresh ideas meet practical know-how.

Europe’s hydrogen highways

The EU’s vision for cross-border hydrogen corridors—from North Sea ports to Alpine valleys—relies on top-notch leak detection at every link. A sensor that thrives in humid ports, spans long pipelines and keeps industrial parks safe slots neatly into this strategy. Though it’s rooted in Swedish labs, the potential reach spans the Nordics, central Europe and beyond.

At the end of the day, this innovation proves that sometimes the smartest move is to work with nature, not against it. By turning humidity into an asset, the team at Chalmers has charted a path toward safer, more reliable hydrogen networks—and that’s a breath of fresh air for the future of clean energy.

source: eurekalert.org

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.