Hydrogen infrastructure expansion in Australia powered by relocatable refuelling stations by Hydrexia

January 23, 2026It’s a big deal for hydrogen infrastructure down under: Hydrexia Pty Ltd is gearing up to roll out relocatable hydrogen refuelling stations from coast to coast in Australia, thanks to a new tie-up with Toyota Motor Corporation Australia Ltd. They’re handling everything—supply, operation and upkeep—for these flexible pump units that back the rising crowd of hydrogen fuel cell vehicles on Aussie roads. After proving the concept in Malaysia and the Philippines, this pact marks a milestone in growing the regional hydrogen economy and tackling the age-old hurdle: making sure drivers can reliably tap into clean energy.

Asia-Pacific network grows

Hydrexia isn’t just sticking to China anymore. They’ve been on a tear across Southeast Asia, Europe, the U.S. and now Australia, flexing their R&D muscles to tailor solutions across the value chain. Partnering up with Toyota again cements their spot as the one-stop shop for everything hydrogen—from production and storage to transport and dispensing. It’s all about creating a global network that can bend and flex to each market’s quirks, whether you’re on a tiny island or cruising the endless Australian outback.

Lessons from Malaysia and the Philippines

Before turning their sights south, Hydrexia teamed up with UMW Toyota in Malaysia and Toyota Philippines to deploy stationary refuelling stations—and boy, did they learn a lot. Working with local hydrogen producers and utility companies, they fine-tuned every detail, from picking the right spots for the stations to calibrating dispensers and smoothing out operations. What started as a technical test quickly proved to be a commercial win: local operators and drivers loved how seamlessly everything worked, setting the stage for the more nimble, relocatable units that Australia needs.

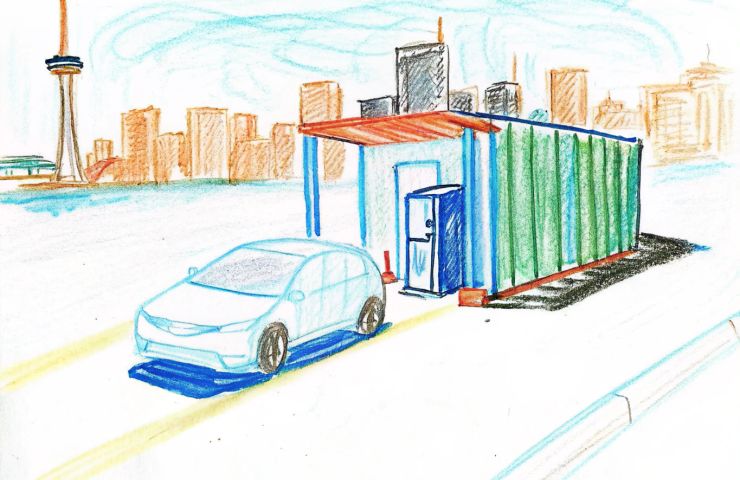

The appeal of relocatable stations

Here’s the trick: you want hydrogen refuelling stations in place, but you don’t have a big fleet yet. It’s the classic chicken-and-egg problem. Enter container-like RHRSs that you can ship in, plunk down at pop-up events, fleet bases or city hubs, then haul off when the demand shifts. No huge upfront investment, no permanent commitment—just roll them in, test the waters and move on if need be. Perfect for Toyota dealers or fleet operators dipping their toes into fuel cell tech without buying the farm.

Tech in focus: how RHRSs work

Under the hood, these stations pack compressed hydrogen in tough-as-nails, high-pressure tanks and shove it into your vehicle at up to 700 bar. They come skid-mounted with modular compressors, cooling loops and safety systems, ready for plug-and-play into a hydrogen line and the local power grid. Packed for travel, they tick all the international safety boxes and can be up and running within days of arriving onsite.

Faster fueling with Twin Mid Flow

Meanwhile, over in Europe, Toyota Motor Europe is working with Hydrogen Refueling Solutions (HRS) and ENGIE under the EU’s RHeaDHy project on something called Twin Mid Flow. This spruced-up nozzle can juice up heavy-duty vehicles in under ten minutes and passenger cars in under five. How? Two high-flow lines in one dispenser—faster fills, fewer headaches and lower installation costs.

Why speed matters

Slow fills—think 15 minutes or more—can stall public station users, but they’re death for busy fleets. Every minute a bus or delivery truck spends stuck at the pump is money—and time—wasted. Twin Mid Flow flips the script: shorter breaks mean trucks and buses stay on the move, boosting efficiency and making hydrogen fuel cells a no-brainer for commercial operators.

Strategic partnership dynamics

For Toyota Motor Corporation Australia Ltd, this isn’t just a check-the-box relationship; it’s co-innovation in action. Teaming their fuel cell electric vehicles with Hydrexia’s on-the-go stations gives them control from tank to tailpipe. And for Hydrexia, Australia’s rigorous safety and vehicle regs are the ideal proving ground. As Ashley Mills, Managing Director of Hydrexia Pty Ltd, puts it, this partnership means Aussies get more choice and a smoother ride into the clean energy future—while Toyota keeps momentum humming by plugging infrastructure gaps before they even open up.

Policy and market alignment

Australia’s push for zero-emission transport is in full swing, with federal and state incentives fueling clean energy projects and earmarking cash for hydrogen refuelling infrastructure. Europe’s dancing to the same tune: the EU’s AFIR rules call for H2 stations every 200 km along key corridors by 2030, and RHeaDHy is right in the thick of it, testing modular station ideas that could be roadmaps for Australia’s own rollout across its vast highways.

Ripples beyond refuelling

Put these relocatable pumps on the map and you’re not just filling tanks—you’re firing up an entire supply chain. Electrolyser plants, tank farms, logistics networks and maintenance crews all get a shot in the arm. More investment in hydrogen production and storage means bigger volumes, bringing costs down. And innovations like Twin Mid Flow keep the industry honest, pushing for faster fills, leaner budgets and user experiences that feel like second nature.

A forward look

As Hydrexia Pty Ltd preps its fleet of RHRS units for delivery, Australia’s hydrogen scene gets a real shot in the arm. Toyota can roll out fleet programs knowing the pumps are there, and policymakers can tick off milestones on their decarbonisation roadmaps. What’s next? Keep an eye out for permanent stations born from RHRS trials, fresh partnerships in the mobility space—and maybe even new automakers jumping in, confident that hydrogen infrastructure is finally catching up to their zero-emissions dreams. Throw in cross-investments with electrolysis outfits and local gas suppliers, and you’ve got a recipe that could make hydrogen a mainstream fuel choice in no time.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.