Hydrogen Storage and Compression: Vallourec and Baker Hughes Join Forces

February 20, 2026Ever wondered what’s been holding the green hydrogen economy back? A big part of the puzzle is building cost-effective, reliable hydrogen infrastructure—especially when it comes to storage and pressure management. This month, Vallourec and Baker Hughes decided to tackle that challenge head-on, signing an MOU to create integrated hydrogen storage and compression solutions. Green hydrogen production has taken off, but scaling up means more than just cranking out molecules. By combining Vallourec’s underground storage savvy with Baker Hughes’ proven compression tech, these two industry veterans are moving from pilots to plug-and-play platforms that ammonia makers, fuel producers, steel mills and power operators can deploy without a drawn-out engineering cycle.

Partnership Overview and Scope

The MOU lays out how the teams will work side by side on engineering, design and optimization of end-to-end storage-compression systems. Vallourec will supply its market-ready Delphy underground storage solution—certified by Bureau Veritas and DNV and capable of holding up to 100 tons of hydrogen—while Baker Hughes integrates its high-performance compressors directly into the inlet and outlet loops. Together, they’ll run feasibility studies with potential users, map site-specific geology and host joint workshops to fine-tune safety protocols. Digital twins of underground formations and real-time compressor controls will steer each design, because syncing storage pressure with compressor performance from day one is the no-brainer way to cut total cost of ownership.

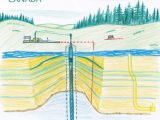

How Delphy and Compression Come Together

Delphy taps decades of tubular-product know-how to pump hydrogen vertically into salt caverns or former gas reservoirs under industrial pressures. Its modular setup arrives pre-assembled with wellheads, safety valves and monitoring sensors that drop right into the shaft. With real-time digital monitoring, redundant leak-detection and remote control at your fingertips, you’re never in the dark. On the surface, Baker Hughes compression units hook up seamlessly to those wellheads, adjusting flow rates and pressure setpoints on the fly. This tight coupling slashes energy losses and makes control way more straightforward than piecing together separate storage and hydrogen compression components.

Strategic Impact on Industrial Decarbonization

Industries aiming to shrink their carbon footprints—think green ammonia plants, sustainable fuel producers and green steel operators—often face the risk of stranded electrolyzers or wasted renewable generation without affordable hydrogen storage. Integrated storage-compression acts as a buffer: smoothing intermittent supply, balancing the grid, stacking seasonal reserves and shaving peak power charges. Even data centers exploring hydrogen-powered backup systems stand to gain from compact, turnkey units. By zeroing in on these use cases, Vallourec and Baker Hughes hope to turbocharge hydrogen adoption and industrial decarbonization where it matters most, while grabbing spot-arbitrage opportunities in volatile power markets.

Placing the Deal in Historical Context

Underground hydrogen storage isn’t exactly new—Europe and North America have tested salt cavern pilots for years—but moving to large-scale commercial deployment has been slowed by issues like hydrogen embrittlement in casings, intricate safety protocols for high-pressure systems and the need for integrated sensor networks. Vallourec’s Delphy solution, with Bureau Veritas and DNV stamps of approval, marks a shift toward prefabricated, repeatable platforms instead of bespoke builds. At the same time, Baker Hughes’ expansion from oil-and-gas services into low-carbon infrastructure reflects the broader push to build out hydrogen infrastructure for the long haul. Their MOU signals that the green hydrogen ecosystem is hitting maturity, moving from R&D experiments to scalable engineering platforms.

Broader Collateral Benefits

A proven storage-compression package from two established players could become the industry’s go-to standard, lowering technical risks for newcomers and catching investors’ eyes. Regulators may also appreciate the streamlined permitting that comes with built-in safety features. Locally, we could see a boost in specialized manufacturing jobs and deeper workforce expertise in cutting-edge hydrogen technologies. And with Baker Hughes’ recent turbine order from Twenty20 Energy for data center power, it’s clear how integrated hydrogen solutions can plug into wider decarbonization efforts. As more companies hunt for one-stop providers, this collaboration could knit the supply chain together—from production right through to power generation.

What’s Next and Forward Look

The MOU is just the starting pistol: both sides are gearing up for feasibility studies and pilot installs, though they’re keeping timelines and investment numbers under wraps. They plan to team up on detailed engineering, site scouting and user trials across multiple regions. Anyone watching the next wave of hydrogen infrastructure will be eager for these pilots—they’ll offer the real-world performance, reliability and cost data that project developers crave. Looking ahead, tightly integrated storage-compression modules could speed approvals and drive down the levelized cost of hydrogen, helping green hydrogen compete head-to-head with conventional fuels.

At the end of the day, by tackling hydrogen storage and hydrogen compression in one fell swoop, Vallourec and Baker Hughes are betting the green hydrogen market can finally break free from siloed engineering. If their approach scales as intended, it could rewrite the playbook for how industrial users plan their hydrogen infrastructure—making it faster, safer and more wallet-friendly to adopt zero-emission tech at scale.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.