New 1 MW Ammonia-to-Power System Leverages Hydrogen Fuel Cells for Zero-Emission Shipping

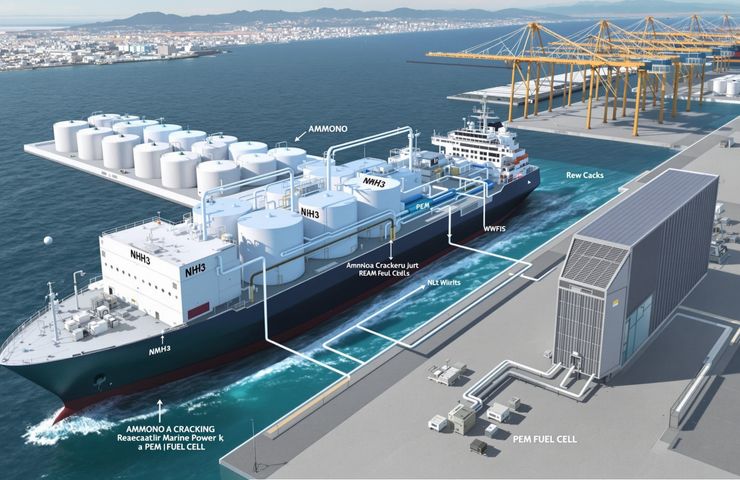

February 2, 2026This month, Vinssen, Samsung Heavy Industries (SHI) and Amogy made waves by announcing a joint project to install a 1 MW-class ammonia-to-power system on commercial vessels. It follows SHI’s strategic investment in Amogy late last year and shows how quickly things can move from boardroom to shipyard. The heart of the system is simple yet ingenious: it cracks clean ammonia onboard using advanced catalyst materials, then feeds the resulting hydrogen into proton exchange membrane fuel cells, producing electricity without a lick of direct combustion. Targeted as a drop-in replacement for marine diesel generators, this pack aims to carve out a big slice of the industrial decarbonization pie and slash carbon emissions in a sector that accounts for nearly 3 percent of global greenhouse gases. What really sets this apart is its modest footprint and the fact it plugs into current fuel bunkering setups, so ship operators won’t have to gut their engine rooms. Instead of wrestling with bulky hydrogen tanks or cryogenic systems, crews can treat the pack pretty much like another generator. That ease of use could be a game-changer on the road to zero-emission shipping.

What’s astonishing is the pace: from the first equity stake to hammering out a manufacturing deal in under a year. That kind of speed signals real industrial confidence in clean ammonia as a zero-carbon fuel. By tapping into existing infrastructure and keeping vessel retrofits to a minimum, the partners are sidestepping the sort of headaches that have tripped up other green fuels. Lee Chil-Han, CEO of Vinssen, says this marks a “huge leap” in steering the maritime industry away from internal combustion engines toward hydrogen fuel cells-based electric propulsion. And with pressure mounting from regulators and customers to embrace sustainable energy, they’re keen to prove ammonia’s drop-in potential before anyone else. It’s also a bellwether for how fast the shipping industry is racing toward its decarbonization goals—and why industrial decarbonization isn’t just a buzzword anymore. With each stakeholder pulling their weight, from catalyst R&D to mass production, the gigafactory-ready vision moves closer to reality.

How the System Works

Let’s peek under the hood at what makes this ammonia-to-power pack tick. At its core is a modular ammonia cracking technology that takes NH₃ and breaks it into H₂ and N₂ right on deck, courtesy of Amogy’s proprietary catalysts. Unlike older systems that demanded sky-high temps, these catalysts do the job at relatively mild conditions, straddling the sweet spot of low energy input and high throughput. Once the hydrogen is freed, it feeds into PEM fuel cells, where an electrochemical dance takes place: hydrogen molecules split at the anode, electrons stream through an external circuit to generate power, and protons glide through the membrane to meet oxygen at the cathode, forming nothing but water. It’s basically a clean electricity factory, with heat and water as the only byproducts—no CO₂, no soot.

On top of that, the design sidesteps the headache of standalone hydrogen storage. There’s no need for mammoth high-pressure tanks or costly cryogenic gear—that bulky hardware is traded for a compact, skid-mounted unit that’s tailor-made for auxiliary power on medium to large ships. In practice, that means less deck real estate, simpler maintenance, and quicker integration into a vessel’s existing power distribution network. Plus, because it uses hydrogen fuel cells instead of combustion, it’s whisper-quiet and delivers instant torque, improving both fuel efficiency and seakeeping comfort for crews.

Collaboration Framework

Each partner in this trio brings a killer feature to the table. Vinssen, the South Korea-based specialist in hydrogen fuel cells, is leading the systems integration and overseeing safety validation—think of them as the chief engineers, making sure every gasket and sensor lives up to the gold standard. Samsung Heavy Industries, riding high on its dual role as investor and contract manufacturer, is committing one of its South Korea facilities to crank out these custom power packs. As Lee Ho-gi, SHI’s managing director, puts it, “This partnership lets us scale eco-friendly fuel systems through world-class manufacturing.” Meanwhile, Amogy is the mastermind behind the catalysts and fuel cell stacks, leveraging its R&D hubs in Brooklyn, Houston and Pangyo.

By fusing Vinssen’s system design, Amogy’s catalytic know-how, and SHI’s shipyard muscle, they’re stitching together an end-to-end supply chain for marine-scale sustainable energy. This alignment not only de-risks the prototype phase but also paves the way for volume deployment—exactly what’s needed to tip the scales toward widescale adoption of ammonia-based propulsion.

Building Capacity in South Korea

SHI isn’t stopping at just a handshake—they’re beefing up their ammonia demo facility at Geoje Shipyard by year-end, adding new test benches, assembly lines, and quality-control stations dedicated to the ammonia power packs. Drawing on the yard’s decades of shipbuilding expertise, this production line is slated to churn out modules for a pilot installation at the Pohang distributed power project next year. Local partners will team up for sea trials and performance monitoring, pushing the system through real-world paces—from rocky weather off the coast to long-duration runs in busy ports.

This expansion will also spawn skilled manufacturing jobs and deepen South Korea’s lead in the emerging industrial decarbonization and clean ammonia economy. By integrating process management systems, raw-material logistics, and advanced automation, SHI aims to deliver consistent output and quality—key ingredients before moving from pilot to full-scale commercial rollout.

Regulatory and Safety Considerations

Of course, handling ammonia isn’t plug-and-play. Its toxicity and special bunkering needs mean operators must have clear guidelines, sophisticated leak detection, and robust emergency response drills. Right now, International Maritime Organization rules for ammonia-fueled vessels are still in draft form, and classification societies are racing to draft class rules for these new power packs. Ports will need to revamp their infrastructure for safe ammonia loading and storage, installing specialized containment, ventilation, and monitoring systems. Getting these safety and regulatory pieces in place is a cornerstone for any serious industrial decarbonization push.

The three partners are already in talks with regulators during the Pohang pilot to refine safety protocols and build a solid approval pathway. Early engagement with maritime authorities, insurers, and local stakeholders will be crucial to de-risk operations, secure certifications, and win public trust. Transparent safety data and crew training programs will help turn skeptics into advocates, smoothing the path for broader deployment.

Why This Matters for Decarbonization

Here’s the crux: shipping is responsible for roughly 3 percent of global CO₂ emissions, and the IMO’s 2050 strategy is turning up the heat on that number. Clean ammonia stands out because it can be synthesized from green hydrogen—created through electrolysis powered by renewable electricity—and then shipped via existing tanker networks. That makes the supply chain for this zero-emission fuel much simpler than pure hydrogen, which often gets bogged down by storage and transport challenges.

By integrating an onboard ammonia-to-power system, shipowners can retrofit their vessels with minimal hull modifications, sidestepping the long lead times and high costs of new LNG carriers or battery conversions. If scaled up, this approach could open up new revenue streams for ammonia producers and supercharge investment in ammonia production facilities. Ultimately, it’s a vital piece of the sustainable energy puzzle, linking fuel supply directly to consumption and driving down the total cost of ownership for greener shipping.

Broader Impacts Beyond Shipping

While the deck is an obvious proving ground, this technology could flex its muscles far beyond ships. Ports, remote industrial sites, and off-grid installations could deploy similar packs for backup power or microgrid support, boosting resilience in areas with shaky grid access. Large-scale factories, data centers, even military bases—anywhere zero-emission power is prized—can tap into modular ammonia-to-power units for clean, on-demand electricity. Plus, thanks to the underlying hydrogen fuel cells technology, these packs deliver higher efficiency and lower maintenance than diesel generators, making them an attractive option across industries and geographies.

This cross-sector appeal has already caught investors’ eyes. Backers like Amazon’s Climate Pledge Fund, SK Innovation, Aramco Ventures, and BHP Ventures are betting that distributed industrial decarbonization via ammonia-to-power will disrupt conventional energy markets. With the same catalytic and fuel cell core, the units can pivot from marine propulsion to stationary power, making them a versatile tool in the transition to sustainable energy.

Next Steps and Future Outlook

What’s on the horizon? First up is the Pohang pilot, which will test the ammonia-to-power packs under variable loads, day-in and day-out, to gather real-world performance data. That intel will inform final design tweaks, maintenance schedules, and long-term cost models. At the same time, ramping up low-carbon ammonia production will be essential—green ammonia needs to get cheaper to beat the price of marine diesel.

Regulatory alignment with classification societies, ports, and insurers will chart the timeline for widespread ammonia bunkering. While methanol, LNG, and batteries each have their strengths, ammonia-to-power boasts high energy density and a straightforward drop-in path for auxiliary power. Early collaboration with insurers will help de-risk operations and cement insurance frameworks. If the Pohang trials hit their targets, expect a ripple effect: more investors will come on board, policymakers will take notice, and further deployments could accelerate the shift toward carbon-neutral shipping.

Charting the Course Ahead

By teaming up cutting-edge catalyst science with shipyard prowess, Vinssen, Samsung Heavy Industries, and Amogy are charting a new course for maritime power. That lightning-fast journey from equity stake to mass-production pact underscores the urgency of decarbonizing an industry that’s long flown under the radar. But the ultimate proof will come when the first ammonia-to-power pack fires up in Pohang’s harbor. As we watch that trial unfold, the maritime and clean energy communities will gain critical insights—and if all goes well, we’ll be one step closer to a zero-emission future on both seas and shores.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.