Portable Electrolyzer Enhances Hydrogen Production for Basque Industrial Decarbonization

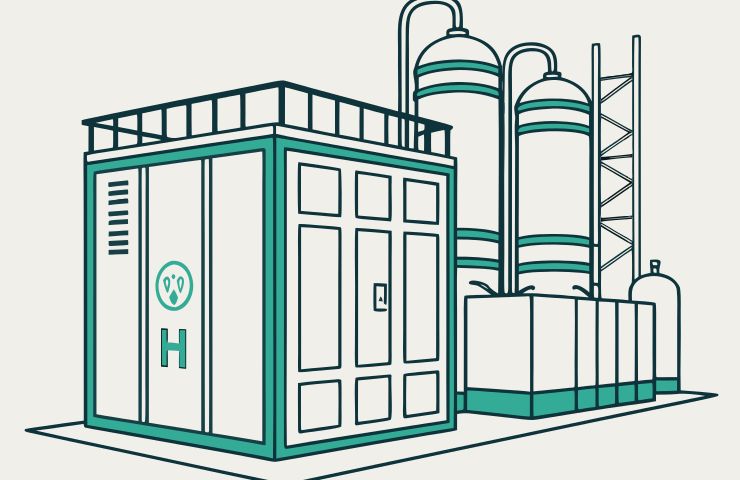

February 2, 2026Ever wondered how green hydrogen jumps from the lab to a full-blown steel mill? Earlier this month, 11 Basque trailblazers led by Sarralle unveiled the H2SKID project: a 1.25 MW containerized electrolyzer that generates, compresses and stores green hydrogen right at the factory gate. Think of it as a mini power station in a shipping container—plug & play, run on renewables, and ready to feed hydrogen into high-temperature processes. That’s industrial decarbonization made real.

A Consortium with Muscle

Under Sarralle’s lead, the H2SKID consortium ropes in a who’s who of the Basque industrial scene. You’ve got Tubos Reunidos Group, ArcelorMittal Sestao, ABC Compresores, Erreka, Flubetech Coatings, Mugape, Sener, Team Group Engineering, Torraval Cooling and Zigor Corporación. From compressors to coatings, each partner brings a unique piece of the puzzle.

Inside the Portable Electrolyzer

At its core, the system is two modules in one container. One handles the electrolysis—using an AEM or PEM stack to split water into green hydrogen and oxygen—while the other module compresses and stores the gas. By skipping fixed pipelines, factories can dip their toes into hydrogen under real-world conditions without a massive upfront build-out.

Seamless Pipes for a Tricky Gas

Tubos Reunidos Group, a stalwart since 1960 known for top-tier seamless steel tubing, is delivering specialized pipes made to resist hydrogen embrittlement and stand up to high pressures. It’s a small but critical detail when you’re pushing hydrogen through burners and furnaces.

From Electrolyzer to Steel Furnace

The first trial kicks off at the ArcelorMittal Sestao plant in Euskadi, replacing natural gas in ladle preheating burners and tunnel furnaces. These long-duration runs will show whether green hydrogen can hit the heat intensity that steelmaking demands.

Why Now? A Historical Arc

Green hydrogen has been climbing the priority list in the Basque Country since the early 2020s, thanks to the EU Hydrogen Strategy and Spain’s own roadmap. Regional clusters like BASQUENERGY and funding streams such as HAZITEK 2025 and EU FEDER 2021–2027 have set the stage—and H2SKID is one of the first big demos to roll out.

Financing and Collaboration

The project runs through 2027 and leans on the Basque Government’s HAZITEK programme and the European Regional Development Fund. Research faces go to Tecnalia and RVCTI agents, while each industrial player chips in core expertise. It’s classic public-private teamwork aimed at beefing up the entire hydrogen infrastructure.

Benefits and Trade-Offs

On the plus side, hydrogen production at the plant could speed up decarbonization in one of Europe’s toughest industries, spark new engineering and maintenance jobs, and put Basque companies on the export map. But let’s be real: electrolyzer capital costs are steep, material science is still catching up to prevent embrittlement, and heavy subsidy reliance raises eyebrows about future economics.

Looking Ahead

As these electrolyzer containers roll into ArcelorMittal Sestao, the consortium is banking on real-world data to light the fuse for broader adoption. If they pull it off, this modular mix of production, compression and storage could head into cement, ceramics or even off-grid industrial parks. It’s not just one steel mill—it’s a blueprint for industrial decarbonization powered by green hydrogen.

Whether you’re in energy policy, manufacturing or finance, keep your eyes on H2SKID. It’s a hands-on test of how to bridge the gap from pilot demos to full-scale hydrogen infrastructure—one container at a time.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.