Ultrathin Nanosheet Catalysts Boost Hydrogen Production Efficiency

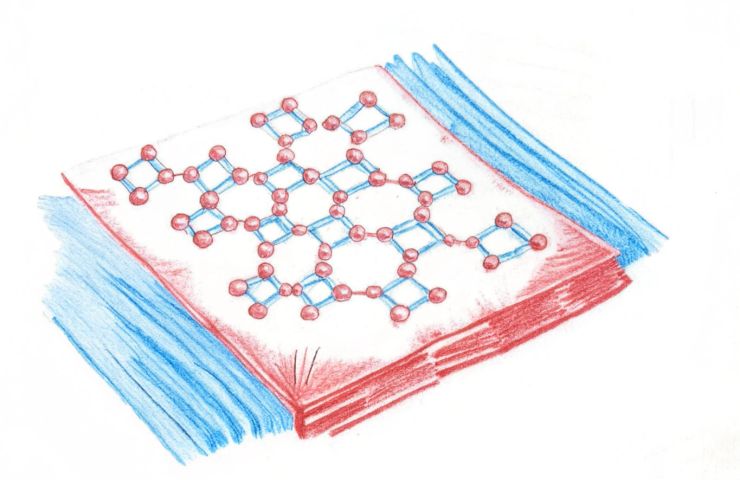

January 25, 2026Ever wondered if a paper-thin tweak could be the secret to affordable hydrogen production? At KAIST, a team led by Professor EunAe Cho thinks so. Instead of clumping precious metals into chunky granules, they’ve coaxed iridium and a platinum-copper alloy into feather-light nanosheets just tens of nanometers thick, all perched on a titanium oxide support. It sounds almost too simple, but by spreading the active surface wide and weaving in natural conductive pathways, they slash how much metal is needed and crank up performance—bringing green hydrogen a big step closer to reality.

Redesigning the Catalyst

Traditional water electrolyzers and hydrogen fuel cells lean on bulky iridium or platinum granules, which send costs sky-high and keep scale small. The KAIST crew turned that idea upside down—literally—by growing ultrathin sheets of iridium or a platinum-copper alloy on a titanium oxide base. Exposing way more active area and carving out conductive paths through what would’ve been resistive TiO₂ makes these ultrathin nanosheet catalysts outperform their granular forebears every time.

Performance That Matters

Under industry‐relevant conditions, the nanosheet setup pumped out hydrogen 38% faster than commercial benchmarks—and did it using 65% less iridium. Even at a grueling current density of 1 A/cm², the electrolyzer kept running strong for over 1,000 hours without breaking a sweat—a durability sweet spot for large-scale electrolysis plants.

On the fuel cell side, those platinum-copper nanosheets delivered a 13-fold jump in mass activity and a 2.3× boost in power output, all while cutting platinum usage by 60%. After 50,000 cycles, they still held onto 65% of their initial mojo—pretty impressive for vehicles or stationary systems that demand long lifetimes.

Why It Matters for Electrolysis

Electrolysis is the backbone of turning renewable juice into storable hydrogen fuel, but the price tag on platinum‐group metals has kept electrolyzers pricey. By slashing iridium loadings and leaning on an inexpensive titanium oxide scaffold, KAIST’s trick could shave up to one-third off electrolyzer capital costs. Faster, tougher catalysts then chip away at operating expenses, making big green hydrogen projects far more bankable.

Implications for Fuel Cell Technology

Whether it’s heavy-duty transport or backup power, fuel cell technology faces the same challenge: precious-metal costs. Using leaner platinum and boosting cycle life drives down total cost of ownership—music to fleet operators’ ears. Even better, these nanosheets slot right into existing fuel cell stacks, so OEMs won’t need a system-wide overhaul to reap the benefits.

Strategic Outlook

With governments and industries racing toward net-zero goals, hydrogen is front-and-center as a decarbonization lever. But to scale up, we need affordable, reliable electrolysis and hydrogen fuel cells. This nanosheet breakthrough tackles two major roadblocks at once—cost and durability—and breathes new life into titanium oxide, a low-cost material traditionally set aside for its poor conductivity.

What’s Next?

The team’s findings are out in two peer-reviewed papers, complete with synthesis recipes and performance data. Lab-to-market hurdles remain—scaling up ultrathin-sheet production and integrating them into mass-manufactured stacks isn’t trivial. Still, industry watchers expect pilot runs within a year and commercial rollouts by the mid-2020s. If those timelines stick, the era of cheaper, greener hydrogen might arrive sooner than you think.

If you’re tracking electrolysis and fuel cell technology, this is a milestone: instead of chasing a brand-new material, a simple structural redesign has unlocked gains that felt out of reach. It goes to show that sometimes the tiniest tweaks—mere nanometers thin—can shift the entire energy landscape.

Source: phys.org

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.