Bamboo-Shaped Flow Field: A Game-Changer in Air-Cooled PEMFCs

August 5, 2025In Asia’s Clean Energy Hubs, a Breakthrough Unfolds

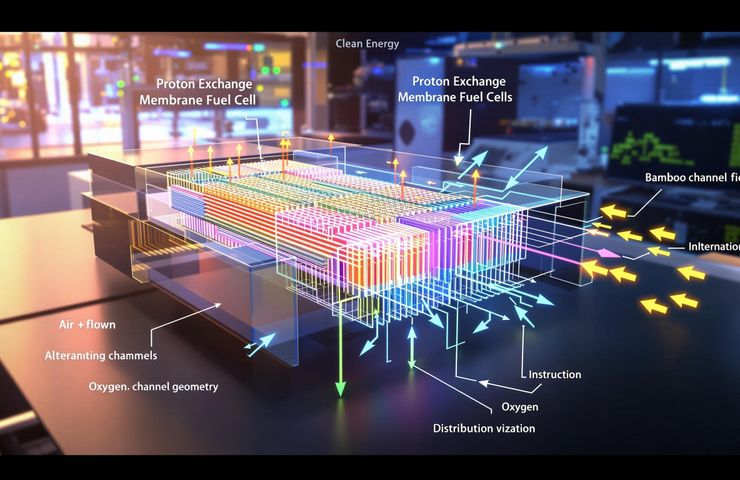

Over in Asia’s busy clean energy labs, something pretty exciting is brewing. A team led by Zhu KQ et al. has rolled out a brand-new bamboo-shaped flow field that’s set to shake up how air-cooled PEMFC (proton exchange membrane fuel cells) perform. And it couldn’t come at a better time: with everyone pushing for zero-emission transport and power solutions, simple yet powerful fuel cell tweaks are exactly what the doctor ordered.

A Legacy of Fuel Cell Innovation

PEMFCs have been on engineers’ radars since the late 1900s as a green alternative for cars and small gadgets. But the classic channel designs—think straight parallel lines or twisty serpentine paths—have hit walls when it comes to keeping things cool and managing moisture under air-cooling. Recently, folks have been borrowing nature’s playbook—heartbeat-inspired curves or plateau-like channels—to tackle dehydration and uneven reactant flow. Still, this bamboo motif really steals the show, blending nature’s geometry with cutting-edge engineering for next-level fuel cell optimization.

A Game-Changer for Air-Cooled PEMFCs

The magic of the bamboo-shaped flow field lies in its alternating channel widths that echo real bamboo joints. That clever twist sparks secondary flows, supercharging oxygen distribution and locking in better membrane hydration. Translation? Fewer dry patches in the membrane electrode assembly, steadier performance, and a longer lifespan. And since it’s tailor-made for air-cooling, you can forget about clunky coolant loops or extra pumps—keeping the setup sleek and simple.

Quantifiable Performance Gains

Don’t just take our word for it—peer-reviewed tests on 25 cm² single cells back it up. Power output jumped by 10.2% to 12.4%, while current density climbed about 11.1% compared to traditional layouts. These aren’t wishy-washy figures; they’re lab-validated numbers showing a real boost in both peak power and day-to-day reliability.

Computational and Experimental Synergy

So how did they nail down the perfect bamboo pattern? By mixing neural network optimization with a genetic algorithm. The AI-driven model quickly predicted how tweaking channel width, spacing, and depth would impact power output and hydration uniformity. Then, the team got hands-on, running a slew of real-world trials to make sure the simulations held true. The result? A design that nails the sweet spot between performance, cost, and manufacturability.

Driving Commercial Viability and Sustainability

This isn’t just an academic exercise. By ditching complex water-management add-ons and boosting reliability, manufacturers can get air-cooled PEMFCs into products faster—and at a friendlier price. That’s music to the ears of EV makers, drone developers, and portable power pack producers, where every gram and watt counts. Plus, fewer moving parts mean less upkeep and a longer device lifespan, cutting down on waste and headaches down the line.

A Glimpse into the Future

We’re at the start of something big. As more labs and startups embrace this bamboo-inspired blueprint, expect a trickle-down effect: quicker product rollouts, wider use of fuel cells in everyday gear, and more emphasis on AI-driven design in energy tech. It’s a quick peek at a future where smart design, sustainability, and teamwork come together to power our world cleaner—and smarter—than ever before.

Access the full paper here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.