China Researchers Boost Fuel Cell Durability with Innovative Frame Sealing Structure

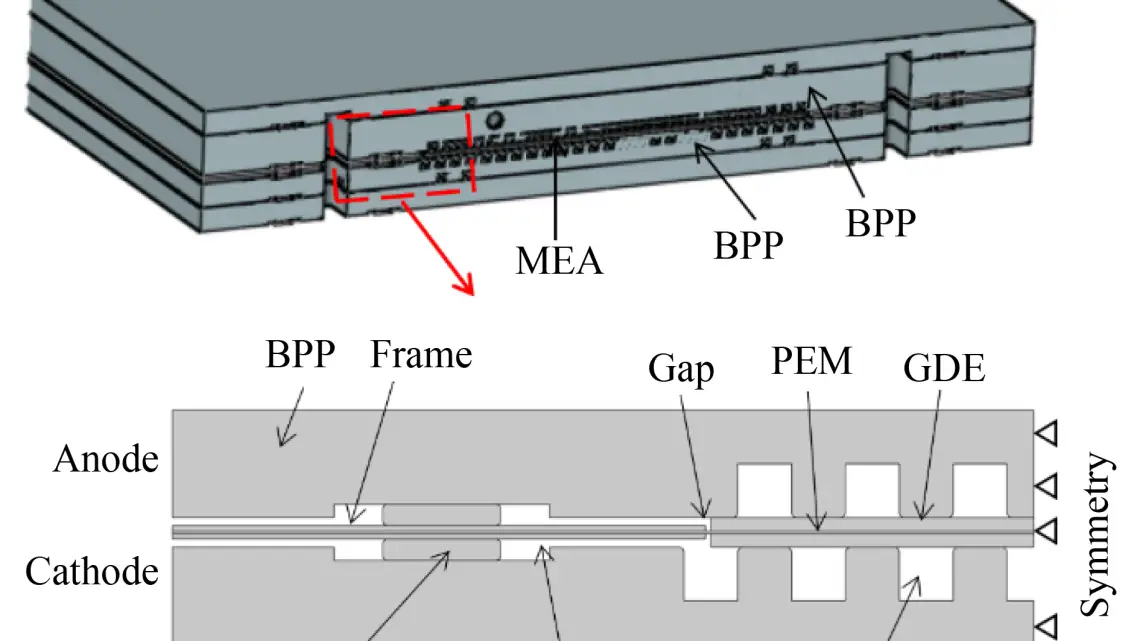

July 11, 2025Researchers in China, specifically from Tongji University and the National Center of Technology Innovation for Fuel Cell, have come up with a surprisingly simple yet effective way to boost PEM fuel cell durability. Their idea? A double-layer frame sealing structure with a cushion layer that helps relieve the mechanical stress that builds up where the membrane meets the frame as the system heats up and cools down.

A Smarter Way to Protect the Core

This new design directly tackles one of the more stubborn weak spots in proton exchange membrane fuel cells (PEMFCs): the membrane electrode assembly (MEA). By reducing the stress and wear in this area, the risk of cracking and deformation drops significantly—two big issues that have limited MEA lifespan in the past. And since the MEA is at the heart of any hydrogen fuel cell, protecting it could be a game-changer.

Getting Closer to the 5,000-Hour Goal

What makes this development so important is that it helps move the industry closer to meeting one of its most ambitious targets: 5,000 hours of operational life for fuel cells in both vehicles and stationary systems. That’s a huge win for everything from long-haul trucks to backup power solutions.

Paving the Way for Cleaner Transport in China

This isn’t just a technical win—it’s a strategic one too. As China continues to ramp up its investment in hydrogen technology and expand its presence in hydrogen mobility, improvements like this make the case even stronger for hydrogen fuel cells as a cleaner, more cost-effective option. Better fuel cell durability means fewer repairs, lower costs over time, and fewer emissions—not to mention a big step forward in the race for sustainable transport solutions.

Source: journal.hep.com

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.