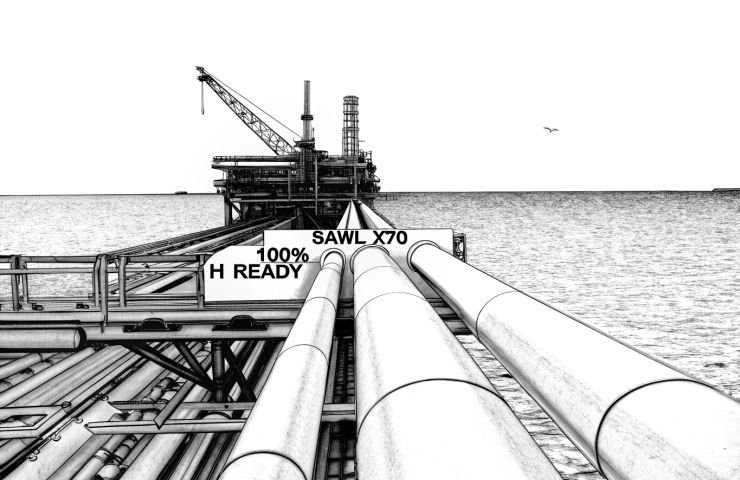

Corinth Pipeworks Confirms Offshore Pipeline Readiness for 100% Hydrogen Infrastructure

August 7, 2025Europe’s hustle to nail its industrial decarbonization and sustainable energy targets has a big hurdle: building safe, dependable routes to ferry pure hydrogen. Well, Greece’s Corinth Pipeworks just cleared a major one. Their SAWL X70 Linepipe—plus the welding wizardry behind it—is officially certified to move 100% hydrogen offshore. That thumbs-up didn’t come easy: in the H₂ lab, pipes faced off against punishing pressures and corrosive conditions. The payoff? Solid proof that tried-and-true steel tech can stand up to tomorrow’s challenges, giving Europe’s hydrogen infrastructure the boost it needs.

A Pivotal Technical Milestone

It kicked off with a deep-dive feasibility study by Corinth Pipeworks and the IGI Poseidon joint venture (that’s Greece’s DEPA International Projects teaming up with Italy’s Edison S.p.A.). Over a series of trials, SAWL X70 pipes were put in simulated offshore conditions—think decades’ worth of hydrogen exposure at pressures up to 100 bar. Why so tough? Hydrogen’s tiny molecules can sneak through steel, causing embrittlement and weakening the pipe. But by the end of the tests, the SAWL X70 grade showed it could keep its mechanical mojo, clearing one of the biggest roadblocks for shipping large volumes of pure hydrogen under the sea.

Why SAWL X70 Matters

Submerged arc welded longitudinal pipes made from the X70 alloy hit the sweet spot between strength and flexibility. The secret sauce? A fine-tuned chemical recipe—including microalloying champs like niobium and vanadium—that tightens up the grain structure and resists crack starts. And it doesn’t stop there. Automated submerged arc welding ensures uniform penetration with hardly any flaws, while precise heat control keeps residual stresses low (killing off extra embrittlement risk). Top it off with post-weld heat treatment and special filler metals, and you’ve got a pipeline that can shrug off the daily grind of waves and currents.

Inside the H₂ Laboratory

At Corinth Pipeworks’ H₂ lab, it’s all about simulating the real-deal environment. Engineers run fracture toughness tests at temperatures and pressures you’d find in North Sea and Mediterranean fields. Fatigue crack growth trials hammer samples through thousands of stress cycles, and hydrogen permeation experiments track how fast H₂ atoms sneak through the steel matrix. Then there are the pressure vessel blowouts, pushing samples to their breaking points to set robust safety margins. On top of that, metallographic exams scour for any microscopic changes—making sure weld zones and heat-affected areas stay crystal clear of embrittlement surprises.

Business and Strategic Implications

Getting the nod for 100% hydrogen service is more than a badge of honor; it’s a serious game-changer for developers, investors, and regulators. Project sponsors can switch from natural gas or hydrogen blends to full-bore hydrogen without reinventing the pipeline wheel—saving time and money. Regulators get to lean on proven specs instead of crafting brand-new rules, speeding up permits. Lenders and financiers can sleep easier knowing material risks are in check, which means better bankability and lower capital costs. And end users—from refineries to steel mills—can plan their hydrogen storage buffer systems and heat applications with confidence that they’ll actually get the supply they need.

“This shift is a tipping point for offshore hydrogen corridors,” an IGI Poseidon spokesperson adds. “With validated pipelines, we can kick off projects linking green hydrogen hubs in the Aegean to markets all the way into Italy and the Balkans.”

Greece’s Role as an Energy Gateway

Poised at a crossroads of Eastern Mediterranean shipping lanes, Greece is fast becoming Europe’s clean energy portal. The country’s maritime legacy and growing LNG infrastructure laid the groundwork for its hydrogen vision. Projects like the Greece–North Macedonia interconnector—built to handle hydrogen down the line—show just how seriously the region is embracing flexibility. And with Cenergy Holdings (Corinth Pipeworks’ parent) offering both steel pipes and cables, Greece is stitching together a corridor that could run from the Eastern Med right into Central Europe’s industrial heartlands.

Backed by EU funds from the Green Deal and Fit for 55 initiatives, the southern corridor has the potential to become a vital artery for green hydrogen—fueling industries from Austria’s steel plants to Germany’s chemical clusters.

Global Context and Industry Impact

Up north in the North Sea and even in Alaska, pilot schemes have tested hydrogen blends and small-scale pure H₂ lines. But Greece’s success is one of the first thumbs-ups for large-scale 100% hydrogen pipelines offshore. It sets a new benchmark for bodies like DNV and ISO, who are racing to nail down standards for hydrogen embrittlement resistance and safety protocols. And it throws a spotlight on European suppliers—led by Corinth Pipeworks—as front-runners in what’s shaping up to be a multi-billion-dollar market by 2030. Across Asia and North America, pipe makers are watching closely, ready to match or raise the bar in their own backyards.

Looking Ahead

With certification in hand, Corinth Pipeworks already has its eye on detailed talks with IGI Poseidon and other consortia to slot SAWL X70 pipes into future export routes. Picture linking island-based electrolysers—churning out green hydrogen—to mainland refilling stations and continental industrial hubs. As electrolyser and renewable power costs keep dropping, the real bottleneck will be moving hydrogen safely and economically—that’s exactly what these pipelines deliver. If everything lines up, those deepwater pipes could soon form the backbone of a trans-Mediterranean hydrogen network, bolstering Europe’s claim to the clean energy crown.

In a field where safety margins and material longevity can make or break multi-billion-euro projects, Corinth Pipeworks’ breakthrough isn’t just talk—it’s a solid green light for offshore hydrogen transport. By tweaking tried-and-tested steel to meet the demands of tomorrow, they’re not just strengthening Europe’s hydrogen infrastructure—they’re helping to define global standards for 100% H₂ conveyance. For everyone from policymakers to project financiers, this is proof that offshore hydrogen pipelines aren’t a distant dream—they’re the next big step toward zero-emission technology.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.