CPH2 Secures £7.4 Million to Advance Membrane-Free Hydrogen Production

September 8, 2025You’ve probably heard the usual gripes about scaling up green hydrogen: astronomic upfront costs, a reliance on rare materials, and maintenance quirks that make folks nervous. If you ask people in the energy game, the real puzzle is balancing cost and reliability while pushing massive hydrogen production at scale. So, in July 2025, Clean Power Hydrogen (CPH2) decided to tackle those hurdles head-on, securing £7.4 million to commercialise its membrane-free electrolyser—a move that dovetails perfectly with the UK’s broader drive toward net zero by 2050 and beefing up national hydrogen infrastructure.

Core Announcement

In a funding blitz—an accelerated bookbuild and a retail share offer—CPH2 pulled in £7.4 million, issuing nearly 148 million new shares and boosting its share count by 40%. Investors, keen for cleaner, more affordable electrolysis solutions, snapped up the offering amid stronger government support and fresh incentives in the UK Hydrogen Strategy. This fresh capital isn’t just numbers on a balance sheet: it’ll fuel R&D, shore up the supply chain, hire top engineers, and kick off manufacturing scale-up. The goal? Get those first commercial 1 MW units out the door by 2026, building on a solid 0.5 MW site test earlier this year.

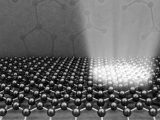

How the Technology Works

Traditional alkaline and PEM electrolysers often depend on delicate membranes and pricey platinum group catalysts, which drive up both capex and the risk of supply bottlenecks. CPH2’s Membrane-Free Electrolyser (MFE) flips the script by blending a straightforward stainless-steel/polymer stack with proven cryogenic separation techniques. Here’s the lowdown:

- Electrolysis Stack: Water mixed with electrolyte runs through electrodes, spitting out a mixed stream of hydrogen and oxygen gas—no membrane barrier in the way.

- Gas Handling: The two-gas cocktail is dried to scrub away moisture, prepping it for the cold treatment.

- Cryogenic Unit: Drop the temperature to roughly –200 °C so oxygen liquefies while hydrogen stays in the gas phase—voilà, a clean split without expensive metals.

- Product Streams: Pure hydrogen gas comes off ready for compression or fueling, and liquid oxygen can be stored or sold to industrial and medical buyers.

This membrane-free take on hydrogen production not only dodges supply-chain snarls for membranes and precious metals, it also leans on cryogenic methods familiar from LNG facilities—making scale-up feel less like a moonshot. According to CPH2’s July 2025 white paper, this combo could push the levelized cost of hydrogen under $1.8/kg with affordable cryogenic cooling.

Strategic Impact

The timing couldn’t be better. As the world barrels toward an annual 10 GW electrolyser capacity by 2030, market analysts expect the sector’s value to jump from under $5 billion today to about $30–40 billion by decade’s end. CPH2’s membrane-free design, which trims capital expenditure by 20–30%, could shake up the industry and lure major OEMs seeking cost-effective solutions.

Energy majors and big industrial-gas players are already poking around for low-cost electrolyser tech partners. Landing that sub-$1.8/kg cost point makes CPH2 an attractive collaborator for companies building out full-fledged hydrogen infrastructure. Plus, with carbon prices in Europe and the UK hovering near £100/tonne CO₂, the economics of low-carbon hydrogen are looking sweeter than ever.

Broader Industry Context

The UK’s blueprint for hitting 10 GW of electrolyser capacity by 2030 and achieving net zero by 2050 has created a playground for innovators. Right now, about 95% of global hydrogen is made from steam methane reforming, accounting for roughly 3% of CO₂ emissions. Membrane-free tech has been on the fringes for years, but separating gases efficiently remained a sticking point—until now. By coupling a simple electrolysis stack with cryogenics—stuff we already trust in LNG plants—CPH2 is turning what was once academic R&D into a concrete step toward industrial decarbonization.

Economic and Environmental Upsides

Axing membranes and platinum group metals cuts material costs and shields CPH2 from commodity-price swings. That opens up the mini-plant market: 0.5–5 MW systems that never made sense with conventional tech now look viable, spawning new jobs across UK clean-tech clusters. And don’t overlook the bonus: liquid oxygen. Selling it to chemical manufacturers, hospitals, or metal fabricators can juice up project returns.

Lowering electrolyser capex also turbocharges green ammonia production, making it more competitive on world markets—a big win for sustainable shipping and fertilizers. Fuel cell makers benefit too, since super-clean hydrogen boosts fuel cell lifespan and reliability—another plus for CPH2’s cryogenic approach.

Risks and Challenges

Of course, there are no magic bullets. Mixing hydrogen and oxygen demands top-grade safety measures that membranes usually handle. CPH2 needs to prove its cryogenic system can sort gases leak-free and endure constant thermal cycling without a hiccup. On the regulatory front, the UK’s Pressure Systems Safety Regulations and other certifications mean rigorous third-party testing—any delays there could shift the commercial timeline.

Supply-chain wrinkles for specialized cryogenic components, potential energy demands for ultra-cold cooling, and lingering questions about long-term operational efficiency are hurdles CPH2 must clear. But each successful test brings more confidence that membrane-free electrolysis can really fly.

What’s Next

With £7.4 million raised, CPH2 is gearing up to expand its UK manufacturing footprint, ramp up pilot deployments, and launch its first 1 MW commercial units by 2026. If all goes to plan, they’ll push into 5 MW modules before the decade’s out. Beyond the UK, eyes are on Germany and the Netherlands, where industrial clusters are dangling incentives for industrial decarbonization. If CPH2 nails its cost and safety goals, we could see electrolyser capex sink by 20–30%, speeding up the global pivot to a zero-emission energy system—and cementing membrane-free electrolysis as a frontrunner in tomorrow’s hydrogen economy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.