Europe’s First Magnetocaloric Hydrogen Liquefaction Pilot Unveiled

September 5, 2025Liquefying green hydrogen without guzzling energy or relying on nasty refrigerants is no small feat. That’s where the HyLICAL consortium steps in. On September 4, 2025, the team at Helmholtz-Zentrum Dresden-Rossendorf (HZDR) fired up Europe’s first pilot for magnetocaloric hydrogen liquefaction. Thanks to a €4.7 million boost from Horizon Europe and the Clean Hydrogen Partnership, this project could shake up how we handle cryogenic hydrogen storage and transport, paving the way for a more sustainable energy future.

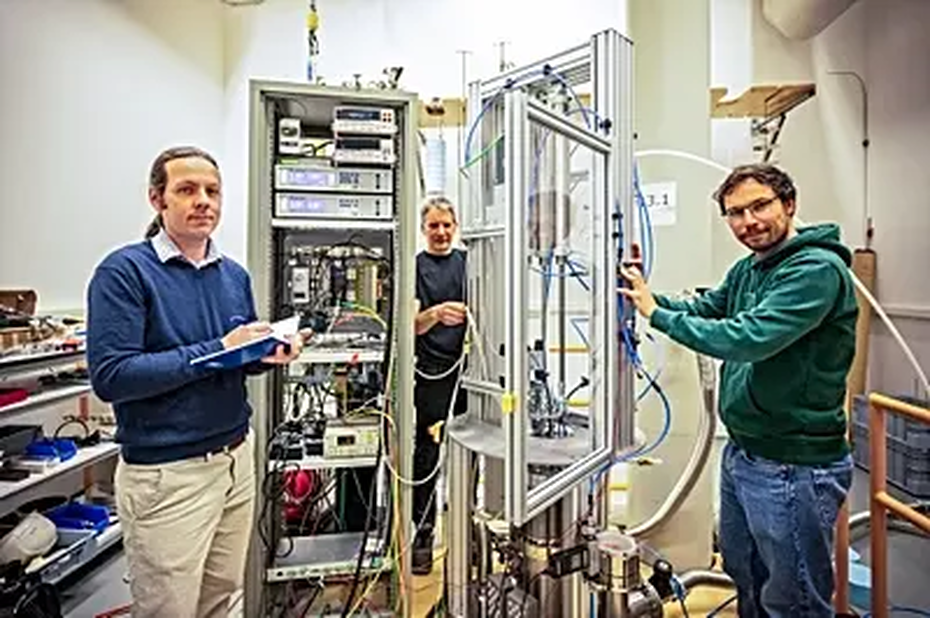

Pioneering Pilot in Rossendorf

If you roll up to the outskirts of Dresden, you’ll find the HZDR campus—an innovation hotspot in Saxony’s long-standing materials and magnet research scene. Leading the charge is Norway’s Institute for Energy Technology (IFE), coordinating HyLICAL with 14 partners from nine EU countries, running through 2027. The team retrofitted a 19-tesla superconducting magnet with modular solid-state cooling units, capable of handling continuous hydrogen liquefaction at several kilos per hour. That’s a pretty big deal for local jobs, too: expect around 20 specialist roles in operations, maintenance, and R&D, plus a welcome lift for nearby suppliers and Saxony’s innovation ecosystem.

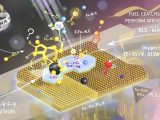

Magnetocaloric Cooling: Deep Dive

At the heart of it all is the magnetocaloric effect. Imagine a material—say a lanthanum-iron-silicon alloy—plunged into a magnetic field: its microscopic dipoles snap into line, heating it up. Yank away the magnet, and it cools down quicker than you can say “cryogenics,” dropping below its original temperature. By stacking several stages—each with its own tailored alloy and clever counterflow heat exchangers—this setup bridges from a –196 °C liquid-nitrogen pre-cool right down to the –253 °C needed for hydrogen. Smart control systems tweak the field strength and timing on the fly, squeezing out maximum efficiency. No HFCs, fewer moving parts, and a much smaller footprint than your typical mechanical compressor.

Energy & Cost Milestones

HyLICAL has its sights set on an ambitious goal—just 8 kWh of energy per kilo of hydrogen and production costs under €1.50/kg. To put that in perspective, today’s commercial liquefiers gulp 10–13 kWh/kg and often rack up bills above €2.00/kg where electricity’s pricey. Nail these milestones, and liquid green hydrogen becomes a real contender—saving money, lightening grid loads, and smoothing the path for industrial decarbonization. Lower power demands also mean fewer headaches integrating with wind and solar-heavy grids, cutting those dreaded peak loads that strain networks.

Strategic Collaboration & Funding

It’s a true team effort. HZDR is hands-on with assembly and technical validation, while German innovator MAGNOTHERM—fresh off opening its second Rossendorf R&D hub in 2024—provides the magnetocaloric modules. Meanwhile, French backer ENGIE New Ventures has put money on the table to fast-track scale-up and stitch together a solid hydrogen transport network. This public-research, agile start-up, and corporate-VC blend shows what can happen when sectors unite to crack the code on low-carbon hydrogen liquefaction.

From Lab to Pilot: A Historic Context

Though the magnetocaloric effect was spotted back in the 1930s, real-world machines have been held back by tricky materials and the need for huge magnets. Traditional cryogenic liquefiers, on the other hand, still lean on multi-stage compressors and fluorinated refrigerants. HyLICAL flips that script—it’s Europe’s (and maybe the world’s) first full pilot to weave magnetocaloric cooling into an entire hydrogen liquefier, from start to finish.

Ripples in the Hydrogen Ecosystem

Should the pilot hit its marks, it could send shockwaves through Europe’s hydrogen supply chain. Rare earth demand for those fancy alloys will climb, nudging suppliers to adapt. High-skill roles in engineering, operations, and maintenance would pepper science clusters like Saxony. Regulators, meanwhile, may spot magnetocaloric systems as a neat workaround to upcoming F-gas bans. On the flip side, scaling up safely will hinge on reliable rare-earth sourcing and syncing the plant with intermittent renewable hydrogen feeds.

Market & Application Landscape

Liquid hydrogen is primed to break open long-haul transport—think deep-sea shipping and aviation—and act as a winter buffer when wind and sun go quiet. The catch? High liquefaction costs have been a showstopper. If HyLICAL’s numbers check out, ports from Rotterdam to Hamburg could become the anchors of new LH₂ corridors, and big industrial hubs could lock in mass deliveries. In energy-hungry sectors like steel and ammonia, where compressed gas doesn’t cut it, liquefied fuel’s energy density is a game-changer. As global LH₂ markets mature, Europe could find itself exporting its green hydrogen know-how worldwide.

Regulatory & Standards Impact

This pilot lands at a pivotal policy moment: the EU is tightening the screws on fluorinated gases and beefing up energy-efficiency mandates. By ditching HFCs outright, magnetocalorics could sidestep future compliance headaches and set fresh performance benchmarks under the next wave of energy directives.

What’s Next for HyLICAL?

Over the next 18 months, the consortium will dial in the pilot—tweaking parameters, harvesting real-world data, and stress-testing every component. If the energy and cost targets stick, the roadmap points to full-scale plant designs by 2027. For anyone tracking the green hydrogen revolution, Rossendorf might just become ground zero for liquid hydrogen’s big break.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.