Fe-Doped Spinel Catalyst Enables Low-Temperature Methane Decomposition

October 16, 2025The Breakthrough

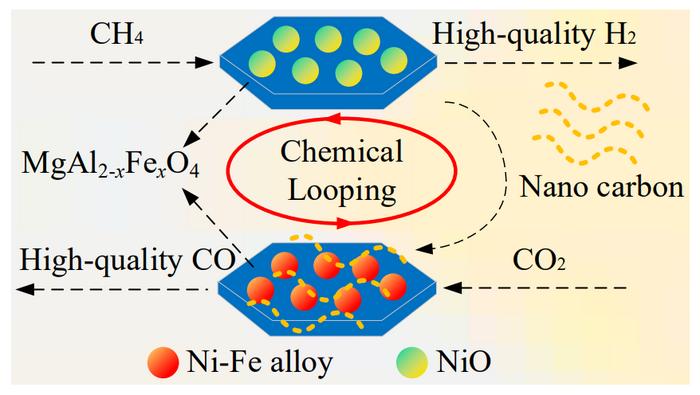

Over in Changsha, the researchers at Central South University have pulled off a pretty neat trick: they’ve developed a fresh Fe-doped nickel magnesium aluminate spinel catalyst that shakes off the usual high heat demands. Instead of needing 800–900°C, it smoothly converts methane into hydrogen at just 650°C. They hit over 91% methane conversion, grabbed hydrogen purity north of 99.5%, and managed to keep carbon deposits—often the bane of reforming catalysts—in check. Led by Zhiqiang Sun, the crew shared the full story in Energy & Environment Nexus on October 1, 2025.

Where & Who

All the heavy lifting went down in Central South University’s cutting-edge labs, nestled in Changsha—a bustling city of over 10 million folks and a real hotbed for materials science. Backed by provincial grants and industry partners, the project brought together metallurgists, surface chemists, and process engineers. Their mission? Tackle two big hurdles: dropping the reaction temperature and preventing that pesky carbon “poisoning” of catalyst surfaces.

Key Results at a Glance

Take a peek at the highlights:

- Methane conversion jumped past 91% at a cozy 650°C

- Hydrogen purity soared above 99.5%

- Ran 20 back-to-back cycles with activity staying above 90%

- Carbon buildup? Dramatically slashed, so regenerating the catalyst is a breeze

How It Works

Here’s the secret sauce: they tweaked the spinel’s crystal lattice by slipping in iron atoms. Those Fe dopants introduce just the right amount of distortion, turning the active sites into methane-cracking powerhouses. With lower activation energy, the catalyst snaps C–H bonds more easily, spawning hydrogen at 650°C instead of the usual roasting temps. Plus, the iron steers carbon leftovers into filament-like shapes that pop off during regeneration—no more surface clogging.

Technical Deep Dive

The team didn’t just guess; they probed every nook of the material using synchrotron X-ray diffraction, high-res transmission electron microscopy, and in situ Raman spectroscopy. Turns out, iron doesn’t just sit pretty—it boosts oxygen vacancies and makes oxygen ions more mobile in the spinel lattice. This dynamic oxygen shuffle continuously sweeps away carbon intermediates, keeping the surface fresh. In bench-scale runs, the catalyst barely blinked: methane conversion stayed within a 5% swing after 20 reaction–regeneration loops—a far cry from standard nickel-based catalysts that can lose up to 30% activity under the same grind.

Historical Context

Traditionally, most hydrogen production has leaned on steam methane reforming or coal gasification—together they spit out over 70% of industrial CO2 emissions. Direct methane decomposition promised a CO2-free route, but it demanded brutal heat and was a magnet for catalyst coking. Folks tried nano-coatings or precious-metal admixtures to ease fouling, yet costs stayed sky-high. This new Fe-infused spinel, however, hits a sweet spot: low-temperature operation, hardiness, and affordability rolled into one.

R&D Journey

This wasn’t a one-off eureka moment; it was three years of tweaking and testing. The researchers dialed iron levels from 1% up to 10% by atomic percent, finding the magic at 5%—that’s where activity and stability lock arms. Each variant zipped through high-throughput microreactor screens, then got a deep dive via surface and bulk analytics. Computational models flagged iron occupying octahedral slots—just as experiments confirmed. Funding flowed from national science boards and green hydrogen innovation grants, spotlighting China’s push on sustainable energy and industrial decarbonization.

Environmental Impact

Switch gears from steam methane reforming to direct decomposition with this catalyst, and you could slash CO2 emissions by around 7.5 kilograms for every kilogram of hydrogen. Scale that to a standard 10,000-tonne-per-year plant, and you’re looking at nearly 75,000 fewer tonnes of CO2 each year. Bonus: the carbon byproduct can be corralled into useful forms like carbon nanotubes or activated carbon—locking away CO2 while generating sellable goodies.

Comparison with Conventional Catalysts

Standard Ni/Al2O3 catalysts often cry uncle after just a few hours, demanding frequent regeneration thanks to coke clogs. By contrast, the Fe-doped spinel sails through five times more cycles before needing a pit stop. Plus, running at 650°C instead of 850–900°C saves energy and eases thermal wear on reactors. Early techno-economic vibes hint at cutting capex by roughly 8%—not too shabby.

Business Implications

Dropping the reaction temp by around 150–250°C can trim energy bills by about 20%. Extended catalyst lifetimes mean fewer shutdowns and swap-outs, potentially hacking hydrogen production costs down by 10–15%. As green hydrogen edges closer to cost parity, sectors from ammonia synthesis to fuel cell tech and industrial decarbonization stand to cash in. If hydrogen pricing dips below $2 per kilogram, you could see a major uptick in hydrogen fuel cells for heavy transport. On top of that, the solid carbon coproducts—think carbon black or battery electrode material—could become fresh revenue streams.

Challenges & Next Steps

Of course, lab glory is one thing; industrial rollout is another. Scaling up means designing pilot reactors that handle bigger flows and incorporate continuous regeneration. The supply chain has to line up high-purity spinel precursors and iron salts, and lifecycle digs must confirm net environmental wins across mining, manufacturing, and operation. Feedstock impurities—like sulfur or siloxanes in biogas—remain wildcards that can foul active sites. The team is eyeing partnerships with energy firms and equipment makers to refine reactor blueprints, add real-time monitoring, and explore carbon credit schemes for the solid residue.

Strategic Alignment

This breakthrough dovetails nicely with China’s 14th Five-Year Plan, which is all about beefing up hydrogen infrastructure and slashing carbon intensity across heavy industries. By teaming up with regional energy companies, the group aims to light up a 500-kg/day pilot plant by mid-2026, drawing in both domestic and overseas investors keen on zero-emission technology.

Looking Ahead

With global hydrogen demand forecast to top 200 million tonnes by 2050 under net-zero roadmaps, innovations like this Fe-doped spinel catalyst could be pivotal. By making hydrogen production more cost-effective and low-emission, Central South University is staking its claim as a clean tech trailblazer. The next year to year and a half will be make-or-break: pilot-scale validation will either catapult this lab marvel into commercial reality or pin it back to the drawing board. If it flies, we could see green hydrogen prices tumble below key thresholds, unlocking fresh markets in transport, power generation, and the broader chemical industry.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.