Fuel Cell Technology Boost: NiFe Alloy and Cerium Oxide Catalyst Elevates Ethanol-Fueled T-SOFC Performance

August 14, 2025Ever wondered what it takes to keep carbon from gumming up a fuel cell when you’re trying to squeeze power out of biomass ethanol? Those tubular solid oxide fuel cells (T-SOFCs) are the hot ticket in fuel cell technology, promising top-notch efficiency, but carbon deposits have been a real speed bump. Now, a team over at China University of Mining and Technology thinks they’ve finally cracked the code.

Core Innovation

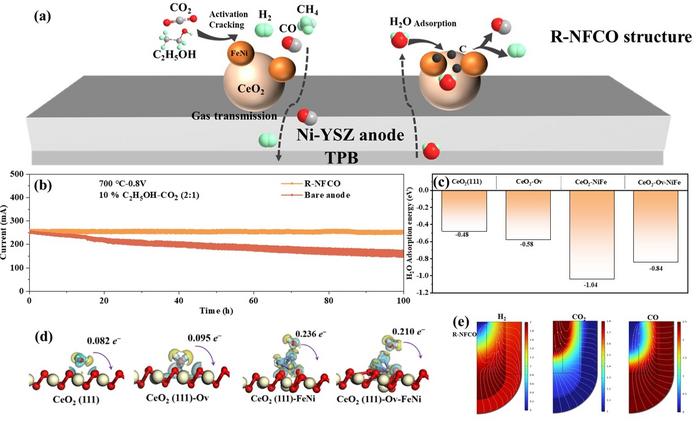

On August 1, 2025, Professor Yihan Ling and her crew dropped their latest breakthrough in the Journal of Advanced Ceramics. They introduced a brand-new NiFe alloy/high-oxygen-vacancy cerium oxide catalyst (R-NFCO) and tucked it into the anode reforming layer of a bioethanol-fueled T-SOFC. The result? A solid bump in electrochemical performance, much smoother fuel conversion, and way better carbon resistance. In lab runs at 700°C with a 10% ethanol-CO₂ mix, this heterostructure kept chugging along for over 100 hours without breaking a sweat. It’s a major leap forward for non-hydrogen SOFC fuels.

Technical Dive: Catalyst Structure

The magic happens at the interface between nickel-iron alloy nanoparticles and a cerium oxide support loaded with oxygen vacancies. Alloying Ni with Fe at the nanoscale hits the sweet spot of high electronic conductivity and boosted catalytic activity. Meanwhile, the ceria (CeO₂) backing gets treated to crank up its O²⁻ vacancy count, turbocharging its redox chops. Together, these features tag-team to speed up ethanol reforming reactions and keep that pesky carbon from fouling the anode.

How It Works: Oxygen Vacancies and Active Sites

Put simply, the NiFe alloy is packed with active sites for kicking off ethanol’s dehydrogenation, while the vacancy-rich ceria lets oxygen ions move fast and furious. When ethanol and CO₂ steam through, they undergo endothermic reforming into H₂ and CO. The ceria layer then swoops in, supplying oxygen ions to mop up leftover carbon—effectively self-cleaning the anode. XPS, XRD and TEM snapshots confirmed more Ce³⁺ and extra vacancies after reduction—a direct line to the catalyst’s boosted performance.

Performance Highlights

- Operational stability: Held steady for over 100 hours at 700°C on a 10% ethanol-CO₂ feed.

- Efficiency gains: Pushed power density up by about 20% versus traditional Ni-based anodes.

- Carbon tolerance: Showed almost zero carbon buildup, unlike rapid coking in control cells.

Structural Confirmation

Diving deeper, transmission electron microscopy (TEM) revealed a uniform spread of ~10 nm NiFe particles across the ceria matrix. X-ray photoelectron spectroscopy (XPS) flagged a nifty 25% jump in surface Ce³⁺ after reduction—proof of those extra oxygen vacancies. X-ray diffraction (XRD) sealed the deal by confirming a pure NiFe alloy phase with no stray byproducts. Altogether, these analyses back up how the heterostructure turbocharges ethanol reforming and holds carbon at bay.

Historical Context: Overcoming Carbon Deposition

Since the ’80s, solid oxide fuel cells have turned heads for their high-temperature operation and fuel flexibility. But feed them hydrocarbons or alcohols like ethanol, and Ni-based anodes tend to choke on carbon deposits, clogging active sites and eroding durability. Early fixes—sprinkling in external oxidants or slap-on ceria coatings—helped a bit but often sacrificed power density or demanded complex pretreatment. Over the last decade, the field shifted toward nano-engineered interfaces and vacancy engineering, setting the stage for R-NFCO’s arrival.

Evolution of Reforming Layers

Early reforming skins leaned on pure ceria or zirconia-ceria blends to store oxygen, but they couldn’t match the conductivity of metal-based anodes. Other experiments toyed with alternate alloys and perovskite catalysts—some curbed coking, others delivered on stability, but none ticked all the boxes. Pairing NiFe alloy nanoparticles with vacancy-rich ceria nails both worlds: the conductivity and mechanical strength of a metal alloy plus the dynamic redox behavior of an engineered oxide support.

Strategic Implications

Imagine regions brimming with agricultural leftovers or bioethanol but lacking hydrogen infrastructure. Deploying compact T-SOFC units that run straight off ethanol means rural electrification, telecom backup power, or microgrids without wrestling with compressed hydrogen logistics. That ties neatly into broader goals around sustainable energy and industrial decarbonization, slashing both emissions and fuel-transport headaches.

On the industrial front, companies chasing carbon neutrality can slot these systems into process-heat or waste-to-energy setups, trimming operating costs while cutting greenhouse gases. By unlocking ethanol’s potential in a high-efficiency SOFC, R-NFCO isn’t just a lab curiosity—it’s poised to reshape how we balance energy needs with environmental targets.

Collateral Impacts

- Boosts bioenergy markets by turning ethanol and agri-residues into valuable fuel.

- Cuts CO₂ footprints compared to diesel generators or grid reliance.

- Speeds up adoption of zero-emission tech in both off-grid and urban settings.

Production and Scale-Up Challenges

Of course, scaling this isn’t a walk in the park. Crafting ultra-pure NiFe nanoparticles and vacancy-engineered ceria demands tight process control and high-grade precursors that could drive costs up. Ensuring uniform catalyst coating on tubular anodes, testing durability against real-world bioethanol impurities, and managing supply chains for cerium and critical metals like nickel and iron are hurdles to clear before R-NFCO can leave the lab.

Next Steps and Outlook

With lab validation in hand, the team’s pushing toward pilot-scale trials and endurance tests under real-world load swings. Their roadmap includes:

- Fine-tuning catalyst thickness and loading on industrial-grade T-SOFCs.

- Running the system on raw bioethanol feeds loaded with typical impurities.

- Integrating heat-recovery setups to leverage high-temperature waste heat.

If these steps pay off, look for commercialization efforts to kick off in niche off-grid markets and expand into broader industrial deployments.

About the Research Team

This project is led by Professor Yihan Ling at the China University of Mining and Technology, a national powerhouse in energy and materials research. Ling’s group specializes in fuel cell catalysts and electrochemical systems, with a string of publications in top-tier journals. Their work on R-NFCO, backed by national science grants, aligns perfectly with China’s strategic push toward sustainable energy, industrial decarbonization and diversified hydrogen production pathways.

Closing Insight

As the energy sector races to hit net-zero targets and broaden its clean power portfolio, breakthroughs like R-NFCO underscore the power of combining materials science with practical fuel strategies. Keep an eye out for pilot programs launching next year—a successful scale-up could rewrite the rulebook on ethanol-powered SOFCs and accelerate our journey to a decarbonized grid.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.