Fuel Cell Technology: Gel-Encapsulated Fibre-Shaped Direct Methanol Cells Power Next-Gen Wearables

August 27, 2025Picture powering your favorite smart shirt with fabric as soft and flexible as cotton thread. In a fresh Nature paper dropped on August 19, 2025, researchers unveiled a breakthrough in fuel cell technology: a gel-encapsulated, fiber-shaped platform for next-gen direct methanol fuel cells that you can bend, snip, and top up in under a minute. It packs an eye-popping 161.36 Wh/kg energy density, runs smoothly from −22 °C to 70 °C, and sails through over 2,000 flexing cycles. That’s a huge leap in weaving high-energy power into wearable electronics—bringing us a big step closer to uninterrupted, seamless juice for our gadgets.

Market Context

As the race for compact, reliable power in health monitors, emergency kits, and the exploding Internet of Things heats up, traditional batteries and rigid fuel cells just don’t cut it. You might get flexibility from solid-state batteries, but they often fall short on energy density. On the flip side, conventional PEM and phosphoric acid fuel cells deliver high output, but only in bulky housings. This new fiber approach leans on a clever gel matrix that self-reinforces under pressure, ditching oversized chambers and setting the stage for truly conformal power in next-gen wearable electronics.

Strategic Implications

If you’re eyeing the wearable electronics or smart textile market, this could flip your playbook. Imagine cutting fuel cell “threads” to size, weaving them into garments, then refueling on the fly at room temp—no clunky equipment required. OEMs and textile pros could embed power directly into clothes, slashing weight, complexity, and e-waste. Even aerospace, robotics, and defense teams stand to gain, thanks to a lightweight, refuelable system that laughs off mechanical stress and temperature swings—a real edge in high-stakes, mobile scenarios.

Business Outlook

Methanol’s no stranger to the global stage—it’s traded in volumes topping 100 million tonnes a year through natural gas reforming and emerging bio-based routes. That means businesses can tap an existing fuel network instead of betting on new hydrogen stations. These gel-wrapped fibers skip pricey extras—no high-pressure tanks or electric compressors—chopping upfront CapEx. For manufacturers, integrating gel-infused threads into textile or composite lines slots right into current weaving and coating setups, keeping unit costs competitive with premium lithium-ion modules. Plus, direct methanol fuel cells boast lower lifecycle emissions than battery production, making them a prime candidate for sustainability incentives or carbon credits. With governments tightening emission targets, jumping on this clean energy train could unlock better financing, speed up approvals, and get your next-gen systems to market faster.

Technical Snapshot

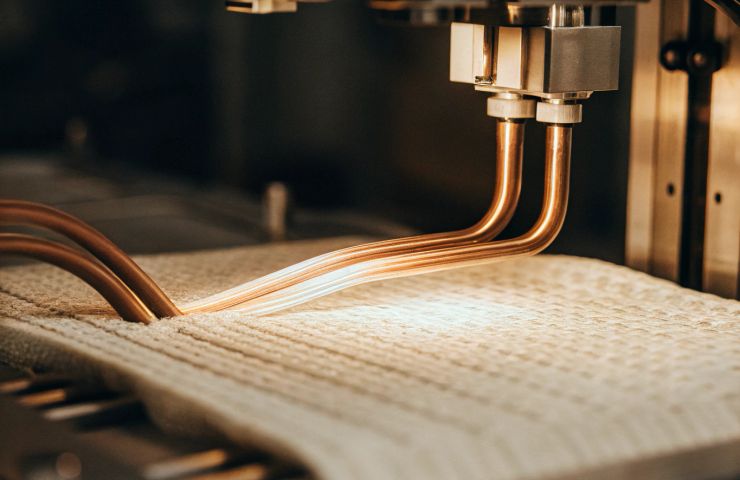

Under the hood, it’s a simple cotton mesh soaked in a methanol-friendly gel. When fuel meets matrix, the gel swells, cranks up internal pressure, seals fuel channels, and locks down electrode interfaces. Here’s the skinny:

- Energy density: 161.36 Wh/kg—blowing past older fiber-based cells.

- Mechanical resilience: 2,000+ flex cycles with zero fuss.

- Thermal range: −22 °C to 70 °C—ready for extreme environments.

- Refuelling: Under 1 minute at ambient conditions—no tools needed.

Parallel Developments

Of course, this isn’t the first rodeo for fuel cell technology or flexible materials. Over the last decade, pioneers toyed with carbon nanotubes and polymer electrolytes, cranking out prototype supercaps and fuel cells that bent okay but tripped up on sealing and power. Back in 2017, an ACS Nano study showed off flexible direct methanol fuel cells with decent flex, but they barely scratched the surface on energy output and quick refueling. In contrast, the new gel-mediated design sets fresh benchmarks in both power and durability, hinting at a real path to commercialization.

Expert Viewpoint

“It’s brilliant how they lean on everyday cotton and a savvy gel to tackle a tough engineering puzzle,” says Dr. Maya Patel, an energy storage whiz not tied to the study. “Locking in pressure control right inside the cell kills the need for heavy hardware and ups longevity. It’s practical, and scaling it could be surprisingly straightforward.” If the numbers hold up, expect to see pilot tests in medical wearables and remote sensors within two years.

Key Takeaways

- A record-breaking 161.36 Wh/kg energy density in a fiber format.

- Cuts to size and lightning-fast (1 min) refueling.

- Stands tough from −22 °C to 70 °C and over 2,000 flex cycles.

- Seamlessly embeds power into textiles, slashing weight and e-waste.

- A fresh clean energy and sustainable energy alternative to bulky batteries.

As the world leans into clean energy and craves seamless integration, this flexible, gel-encapsulated platform could be a game-changer. It marries high energy density with rugged, textile-friendly form factors, cracking open new horizons for commercial wearables, defense gear, and beyond. Keep an eye out: textile manufacturers and energy outfits could kick off pilot programs by late 2026, setting the stage for consumer rollouts in the early 2030s.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.