Fuel Cell Technology Gets a Boost from 2D Topology-Curvature Optimization

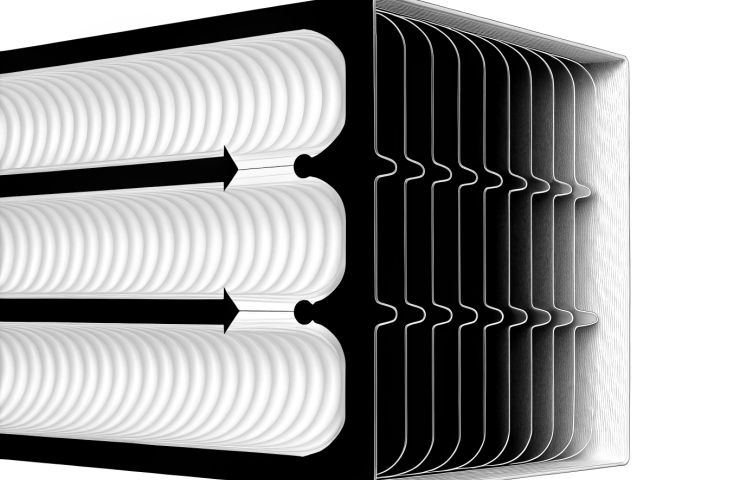

July 8, 2025Youliang Cheng and his team have come up with a smart new way to get more out of proton exchange membrane fuel cells (PEMFCs). It’s called 2D Topology-Curvature Optimization, and it’s all about fine-tuning the shape and curves of the flow channels inside the cells to make them work better.

A fresh take on fuel cell design

The research, published in July 2025, shows that by reworking how gases and heat move through the fuel cell, they managed to bump up the peak current density by 4.72% and the power density by 3.12%. That might not sound huge at first glance, but in the world of fuel cell technology, gains like these can make a serious difference—especially when it comes to improving hydrogen fuel cells for real-world use.

Efficiency with real-world impact

The cool thing here isn’t just the performance boost; it’s that they didn’t sacrifice practicality to get it. Instead of chasing raw power alone, Cheng’s team used something called an efficiency evaluation criterion (EEC) to keep things balanced, focusing on meaningful, real-world improvements. Their approach makes it easier to avoid costly pressure losses—something that often trips up other PEMFC optimization efforts.

What it means for clean energy tech

If this method gets scaled up, it could help bring down costs and make hydrogen fuel cells a much more attractive option across industries—from transportation to power generation and more. Of course, there’s always a catch: with more complex design comes tougher manufacturing. That’s where next-gen techniques like additive manufacturing could really shine, helping turn innovative designs into mass-producible solutions.

All in all, this is a promising step forward in sustainable energy and fuel cell technology, and one to keep an eye on as the industry continues to evolve.

Source HEP Journals.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.