Green Ammonia: SPIC Launches World’s Largest Non-Biological Ammonia Synthesis Unit

November 4, 2025The Big Reveal

Ever thought fertilizer could go from dirty to dazzling?, SPIC has fired up the planet’s biggest Non-Biological Ammonia Synthesis plant, churning out a mind-blowing 180,000 metric tons a year. This beast of a facility sits at the heart of China’s national clean and Low-Carbon Energy hydrogen demo project. It’s not some lab experiment—it’s live, it’s loaded, and it’s here to prove that industrial-scale, zero-fossil Green Ammonia isn’t sci-fi—it’s tomorrow’s reality.

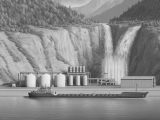

You’ll find this mega-plant planted smack in an industrial zone that’s perfectly positioned between booming wind farms, solar parks, hydro dams, and the major fertilizer distribution hubs. Picture row after row of electrolysers humming away, fueled by sun and wind, spitting out pure Clean Hydrogen that feeds straight into next-gen ammonia reactors. No natural gas. No CO₂ belching out of chimneys. It’s a world-first demo that’s got the whole planet leaning in for a closer look.

Why It Matters

If you ask me, chemistry’s been stuck in a time warp since the 1910s—thank you, Haber-Bosch. That old-school method has fed us ammonia fertilizer for over a century, but at the cost of burning boatloads of natural gas and pumping out roughly 1.5 to 2 tons of CO₂ for every ton of ammonia. Global emissions? Hundreds of millions of tons every year. Not exactly a recipe for a green future.

Here’s the kicker: ammonia is at the heart of feeding more than half the world’s population. Yet until now, dialing down its carbon footprint has felt like trying to teach a dinosaur to dance. Enter SPIC, flipping the script with green hydrogen instead of fossil feedstocks. This isn’t just putting a band-aid on the problem—it’s a full reboot of a system that’s been chugging on fossil fuels for decades. With net-zero targets breathing down our necks, this kind of shake-up can’t come soon enough.

The Magic Ingredient

So, what’s the secret sauce? It all comes down to renewable-powered water electrolysis. Basically, you send electricity from wind turbines and solar panels into water, and voilà—you split H₂O into hydrogen and oxygen. No methane. No CO₂. That freshly minted Clean Hydrogen then hooks up with nitrogen pulled from thin air in a Haber-Bosch reactor, cooking up molecule after molecule of ammonia.

But SPIC didn’t stop at swapping out fossil fuels. Their R&D wizards tweaked catalyst recipes and fine-tuned reactor designs so they’re squeezing more ammonia out of every megawatt-hour. Early runs show a sweet 10% drop in energy use compared to other green ammonia demos. Hit that kind of efficiency, and green ammonia starts looking like a genuine rival to grey ammonia on cost pretty fast.

Live and in Action

This isn’t a side gig or a pilot project you see blinking on a control panel. In Phase I, SPIC is pumping out 180,000 mt of Green Ammonia every year—an industrial-scale beast that leaves smaller demos in the dust. The plant’s hooked up to SPIC’s own renewable energy grid, so when the wind picks up or the sun’s blazing, any extra juice flows straight to the electrolysers. Grid ups and downs? No sweat. Excess power gets soaked up, keeping everything humming along.

And because this puppy is part of China’s national clean and Low-Carbon Energy hydrogen demonstration project, it’s got all the perks: sweet tariff deals, tax breaks, you name it. That kind of back-end support doesn’t just grease the wheels—it sends a giant neon sign reading “invest here” to every corner of the market.

Behind the Scenes

Don’t let anyone tell you SPIC is a green rookie. Born in 2015 from the merger of China Power Investment Corporation and State Nuclear Power Technology Corporation, this state-owned titan wears many hats—hydro, nuclear, solar, wind, you get the drift. With a whopping 176 GW of installed capacity and a cool USD 40.1 billion in 2020 revenue, they’re one of the world’s top electricity players. Now they’re channeling that muscle into decarbonization, shooting for over 60% renewables by 2025 and beefing up their hydrogen footprint at home and abroad.

Under China’s 14th Five-Year Plan, hydrogen and ammonia are major darlings of government support. Grants? Check. Infrastructure co-investment? Double-check. SPIC’s playbook mixes private partnerships, public funding, and in-house R&D to build a seamless low-carbon ecosystem. They’re teaming up with electrolyser makers and catalyst experts, while their own construction and maintenance arms keep costs from ballooning. It’s a full-court press from lab bench to factory floor.

Ripple Effects

Once Green Ammonia moves off the drawing board and into actual production, it’s going to shake up more than just fertilizers. Farmers get cleaner feedstock for crops. Utilities could burn ammonia in power plants, using it as both fuel and storage. Shipping? Ammonia-fueled engines could become the new normal, thanks to its high energy density and existing liquefaction tech.

On the economic side, think thousands of jobs building and running these facilities. But legacy ammonia producers and natural gas suppliers might feel the heat as green alternatives gain ground. Trade balances could shift, with new clean ammonia export hubs popping up on the global map.

Gaze into the Future

Looking ahead to Phase II, SPIC’s aiming for a whopping 500,000 to 1 million mt/year capacity. Picture cargo ships loaded with Green Ammonia steaming across oceans to Europe, where they’ll be cracked back into hydrogen for steel mills and refineries. Off-grid mining camps could run on ammonia-fed turbines, ditching diesel for good.

New business plays are already taking shape—“ammonia-as-a-service” subscriptions, microgrids that burn ammonia on-site, even cross-border trading platforms treating ammonia like LNG. Financial markets are circling with green ammonia bonds and sustainability-linked loans to bankroll these ventures.

For SPIC, this isn’t just another project—it’s a turning point, morphing from a run-of-the-mill utility into a full-blown green energy powerhouse. For everyone else, it’s a clear signal: the low-carbon ammonia era has begun. Buckle up, because this ride’s just getting started.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.