Green Hydrogen Production Soars with Zn-Substituted Cobalt Ferrite Nanocatalysts

August 18, 2025Hydrogen’s rise as a zero-carbon fuel really hinges on breakthroughs that can drive down costs and pump up efficiency. In a Scientific Reports paper from July 8, 2025, a team in India introduced zinc-substituted cobalt ferrite (ZnxCo1−xFe2O4) nanocatalysts designed to supercharge green hydrogen production through both photocatalysis and electrocatalysis. Their headline act, Zn0.06Co0.94Fe2O4, delivered a whopping 21.51 mmol of H2 per gram of catalyst in eight hours, outpacing previous spinel ferrite contenders.

Core News Summary

These catalysts emerge from a sol-gel auto-combustion route, yielding uniform nanoparticles with an ideal electronic band gap (1.69–1.91 eV) and magnetic traits that make recovery a breeze. When tested under UV-driven photocatalysis and acidic electrocatalysis—a form of electrolysis in 0.5 M H2SO4—they clocked high hydrogen evolution rates while staying robust and recyclable over multiple cycles.

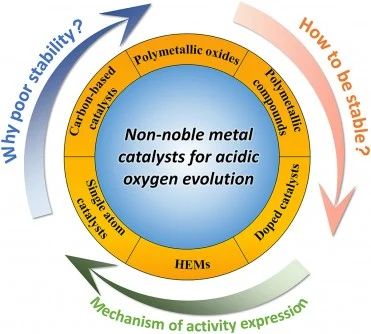

Technical Deep Dive

Spinel ferrites like CoFe2O4 are celebrated for their chemical toughness and tunable electronics. By swapping some Co2+ for Zn2+, the researchers fine-tuned the band gap and cranked up the number of active surface sites. The sol-gel auto-combustion trick yields nano-sized particles (around 20–50 nm) with high surface area—essential for slick water-splitting chemistry.

Under photocatalysis, UV light excites electrons into the conduction band, spawning reactive species that split water into H2 and O2. In this mode, the Zn0.06 variant hit 21.51 mmol gcat−1 of H2 in eight hours—about 30% better than undoped CoFe2O4. Switching to electrocatalysis, a thin film on carbon paper slashed the overpotential for the hydrogen evolution reaction, maintaining 10 mA cm−2 at roughly 280 mV—on par with pricier noble-metal catalysts.

Strategic Implications

This comes at a critical moment: global policy pushes for sustainable energy and industrial decarbonization, yet cost remains the biggest hurdle for green hydrogen adoption. By leaning on abundant metals (Zn, Co, Fe) and a straightforward synthesis, these catalysts offer a cost-effective alternative to platinum or iridium electrodes. Their magnetic recoverability also slashes operational costs by making catalyst separation and reuse a snap.

For companies eyeing large-scale electrolysis plants or solar-driven hydrogen facilities, even a modest bump in efficiency could cut electricity bills by 15–20% per kilogram of H2—a game-changer when margins are tight. With India’s hydrogen economy ambitions backed by policy incentives and growing renewables, this innovation couldn’t have come at a better time.

Scaling Up: Opportunities and Hurdles

Lab results look promising, but real-world deployment demands pilot trials. Spinel ferrites excel in controlled settings, but industrial reactors deal with shifting temperatures, pressure swings, and water impurities. The team’s next steps include testing under simulated solar spectra and integrating the catalyst into membrane-electrode assemblies for a more realistic challenge.

Supply-chain factors also loom large. Cobalt mining raises environmental and ethical flags, and ramping up Zn-doped ferrite production needs careful sourcing to avoid unwanted ecological impacts. Plus, rolling out green hydrogen in water-scarce regions calls for robust recycling and purification systems—otherwise you’re just swapping one resource crunch for another.

Forward Look

This breakthrough underscores how material science can reshape the economics of green hydrogen and hydrogen production. If pilot tests confirm the lab-scale performance and durability, Zn-substituted cobalt ferrite catalysts could become a cornerstone of next-generation electrolysers and solar-driven systems. As governments and industry race toward Net Zero, innovations like these will be pivotal for hydrogen’s bid to become a mainstream energy carrier.

For now, the data are clear: Zn0.06Co0.94Fe2O4 sets a new benchmark for non-noble metal catalysts. The ultimate test will be scaling from milligrams in the lab to gigawatt-level operations—something worth watching over the next year.

Source: “Boosting green hydrogen generation using Zn-substituted CoFe2O4 catalysts,” Scientific Reports, Nature Publishing Group.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.