Green Hydrogen Surge: Linde and Air Liquide Drive Electrolysis for Industrial Decarbonization

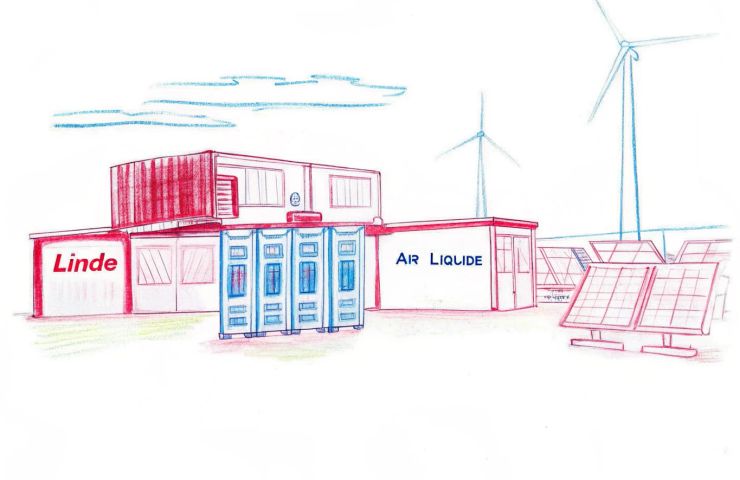

October 24, 2025If you’ve been following the energy shift, you’ve probably seen green hydrogen popping up on every roadmap. But it’s only now—thanks to giants like Linde and Air Liquide diving into big-time electrolysis projects—that truly carbon-free hydrogen production feels within reach. These two heavy hitters know their stuff—they’ve been selling hydrogen from fossil fuels for over a century. What’s new is their all-in bet on renewable-powered processes, kicking off a fresh chapter in global industrial decarbonization.

Take early 2024, for instance. Air Liquide flipped the switch on one of the planet’s largest green hydrogen hubs in Quebec, tapping into hydropower to feed an alkaline electrolyzer that tears water apart into H2 and oxygen. This isn’t a one-off demo—it’s built for continuous, multi-year operation, complete with digital twins and predictive maintenance to squeeze out every drop of efficiency. Not to be outdone, Linde teamed up with Shell on Germany’s REFHYNE II plant—a 100-MW electrolyzer that will roll out roughly 44,000 kg of green H2 per day, feeding into Shell’s Antwerp network of refineries and chemical hubs. Beyond these flagships, both firms have their eyes on sites near Baja’s solar farms, Texas wind belts, and Scandinavia’s tidal streams—anywhere cheap renewables and friendly policies, like the EU’s REPowerEU and the US Inflation Reduction Act, are on tap.

The Electrolyzer Push

At the core of this shake-up is the electrolysis tech that makes hydrogen production genuinely clean. You feed water into an electrolyzer and zap it with electricity, splitting H2O into hydrogen and oxygen. There are two main camps: proton exchange membrane (PEM) systems—which are super responsive to dips and surges in renewable power, handling rapid ramp-ups when the sun pops out or wind gusts kick in—and alkaline electrolyzers, known for their steady, long-haul performance at lower upfront costs and proven reliability. Both types have seen capex drop by 30% over the past five years, thanks to material innovations and scaled-up manufacturing. Rather than just buying off-the-shelf units, Linde and Air Liquide are layering on their own software, advanced catalyst coatings, and thermal-management tricks to boost durability and uptime. The result? Longer stack lifetimes, less maintenance downtime, and a clearer path to sub-$2/kg hydrogen.

Scaling Up with Renewables

Slapping electrolyzers in a field isn’t enough—massive, cheap renewable energy is the real linchpin for making green hydrogen economically viable at industrial scale. Over in Quebec, Air Liquide taps spillover hydropower, ensuring its electrolyzer hums 24/7 on zero-carbon juice. Germany’s REFHYNE II plant kisses the grid from wind and solar farms, proving how a diverse renewables mix can smooth out peaks and valleys. In the US, teams are signing long-term PPAs with solar developers in the Southwest and wind operators in the Central Plains to lock in rates below 2¢/kWh. They’re even exploring battery-hydrogen hybrids, where excess solar charges batteries or runs electrolyzers during off-peak hours. By co-locating production with energy hotspots and lining up off-takers—food processors, data centers, and even carbon-capture facilities—they’re slashing transmission losses and hedging against wild power price swings. That’s the secret sauce for cost-competitive green hydrogen.

Strategic Stakes in the Hydrogen Economy

Why the sprint? For starters, subsidies and incentives for clean fuels have dwarfed what fossil fuels used to get—and that shifts the balance sheet in hydrogen’s favor. Linde and Air Liquide see industrial decarbonization as prime real estate: steel mills, refineries, and chemical plants are crying out for low-carbon feedstocks that slip into existing pipes and reactors. Europe’s carbon pricing, the US IRA credits, and Asia’s green industrial zones are all driving serious capital into green H2. By staking their claim early, these companies lock in key partnerships, snag grid hookups, and build out their engineering muscle. Emerging players like Nel, ITM Power, and local state champions are hot on their heels, but with decades of pipeline operations and safety protocols under their belts, Linde and Air Liquide have a head start. Plus, offering “green” gas is no longer a nice-to-have—it’s a must-have if you want to stay in business as net-zero targets bite deeper.

Building a Hydrogen Infrastructure

Churning out green hydrogen is just half the battle—getting it around and stashing it away poses its own puzzles. Both Linde and Air Liquide are testing hydrogen blending in old-school natural gas pipelines to see how much H2 you can sneak in before you need new alloys. They’re building dedicated compression stations and rolling out advanced cryogenic tanks for liquid hydrogen, plus piloting tube trailers and rail cars for regional distribution. At ports, they’re retrofitting terminals to load H2 barges, and on highways, green-hydrogen fueling stations are popping up alongside EV chargers. Plans for mega hydrogen hubs in Germany’s Ruhr Valley, France’s Grand Port Maritime, and Texas’ Gulf Coast aim to cluster producers, end-users, and storage caverns—creating a local hydrogen infrastructure that slashes logistics costs and speeds up roll-out.

All this momentum comes with some nice side gigs: a spike in jobs—engineers, construction crews, renewables experts, even software developers for digital twins—especially in regions bursting with wind, solar, or hydro. Communities that once depended on coal mines are getting a second life building electrolysis modules. Countries diversify their energy mix, boosting security and cutting ties to imported oil and gas, which helps buffer against geopolitical shocks. But let’s not sugarcoat it—upfront capital costs still run into the hundreds of millions, regulations vary wildly, and there’s a real need to train thousands of operators, welders, and safety inspectors. Financing remains tricky for first-of-a-kind plants, though green investment banks and blended-finance tools are stepping up. Yet if you look at the trendlines, green hydrogen is snapping out of its niche and stepping into the mainstream of heavy industry.

Looking Ahead

So, will these headline-grabbing projects tip the scales toward a hydrogen-powered future? Honestly, they already are. Every new electrolyzer, every extra megawatt of renewables, nudges costs down and makes hydrogen production more wallet-friendly. We’re also seeing spillover benefits in mobility: hydrogen trucks, trains, and even ships are lining up for supplies. Blending hydrogen with natural gas is proving a low-impact way to decarbonize buildings, and seasonal storage in salt caverns offers a grid-balancing ace up our sleeve. Sure, we’ll need gigawatts more renewables, smoother permitting, and crystal-clear regulations. But Linde and Air Liquide have shown the tech is ready to ramp and the market is primed. Keep your eyes peeled over the next year—you’ll see more electrolyzer capacity come online and a clearer roadmap toward decarbonized steel, chemicals, ammonia, and beyond.

About Linde

Linde plc is a global industrial gas leader based in Ireland and the US, with more than 80,000 employees and operations in over 100 countries. Founded in 1879, it specializes in gas production, processing, storage, and distribution—ranging from medical oxygen to liquefied natural gas. These days, Linde is pouring billions into green hydrogen, electrolyzer research, and digital services. Its Shell REFHYNE II project in Germany is just one megawatt-scale example of Linde’s knack for integrating, operating, and optimizing large-scale clean-energy plants around the world.

About Air Liquide

Air Liquide, founded in 1902, is a French industrial gas powerhouse with about 66,000 staff and a footprint in 80+ countries. It’s long been a leader in hydrogen production for refineries and ammonia factories, and now it’s pivoting hard into electrolysis and green hydrogen solutions. Its Quebec facility, one of the world’s largest green hydrogen plants, runs nonstop on hydroelectric power. With ongoing investments across refining, chemicals, mobility, and even aerospace, Air Liquide is tightening its grip on deep industrial decarbonization and building the backbone of tomorrow’s low-carbon economy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.