Green Hydrogen Valleys: India Launches HVICs to Scale Hydrogen Production and Decarbonize Industry

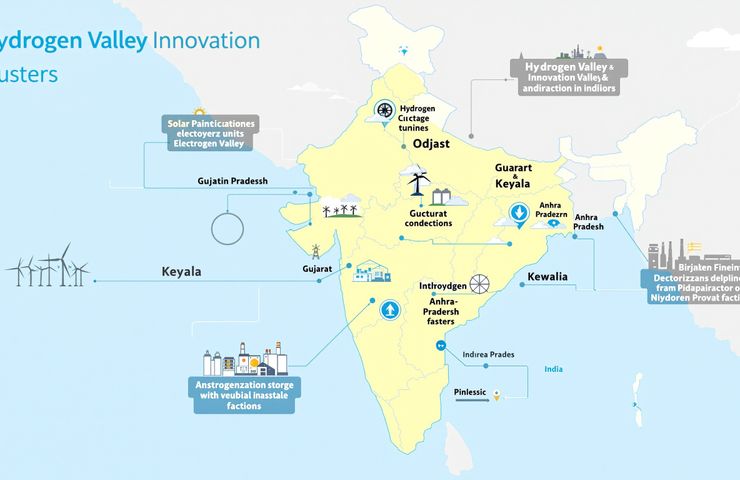

November 18, 2025On November 2025, Minister of State for Science and Technology Dr. Jitendra Singh kicked things off with a landmark initiative under the National Green Hydrogen Mission: four brand-new Hydrogen Valley Innovation Clusters (HVICs) spread across India. Spearheaded by the Department of Science and Technology (DST) in tandem with the Ministry of New and Renewable Energy (MNRE), the plan is to showcase the entire green hydrogen value chain—from renewable-powered electrolysis and hydrogen storage right through to transport and industrial use.

These HVICs build on India’s COP26 promise to hit 500 GW of non-fossil capacity by 2030 and borrow a page from Europe’s hydrogen-valley playbook, where you’ve got regional renewables, production, storage and demand all under one roof. Tied into the bigger Atmanirbhar Bharat push, the clusters aim to spur home-grown electrolyzer technologies, slash import dependency and set India up as a leading exporter of clean hydrogen and its derivatives by decade’s end.

- Launch Date: 13 November 2025 at the International Conference on Green Hydrogen (ICGH–2025).

- Key Players: DST (concept lead), MNRE (policy & funding), Anusandhan National Research Foundation (R&D integration).

- Locations: Odisha, Gujarat, Kerala, Andhra Pradesh—picked for their mineral wealth, solar/wind potential, port access and industrial hubs.

- Funding: Total ₹485 crore—₹169.89 crore from NGHM and ₹315.43 crore from private-sector consortiums.

- Main Goals: Pilot large-scale hydrogen production, refine storage solutions, validate fuel-cell tech and nail down regulatory/business frameworks for scaling.

“With these clusters, we’re laying the groundwork for net-zero industry corridors, energy security and export-led growth,” said Dr. Jitendra Singh at the launch.

Technical Blueprint

Here’s the scoop: each cluster will roll out both proton exchange membrane (PEM) and alkaline electrolyzers, flexibly hooked up to solar farms and wind parks. We’re talking pilot capacities in the 5–20 MW range per site, aiming to churn out thousands of tonnes of hydrogen every year. Key pieces of the puzzle include:

- Electrolysis Units: A mix of grid-tied and standalone systems with smart power management to squeeze every drop of renewable juice and boost capacity factors.

- Storage & Handling: High-pressure vessels (350–700 bar), cryogenic liquid setups and cutting-edge metal-hydride materials—all under automated safety checks.

- Fuel Cell Demos: Multi-kW stacks powering everything from microgrids and forklifts to peak-shaving turbines and early gas-turbine blends.

These live demos are all about fine-tuning system efficiency, shaving off energy penalties and driving down the levelized cost of hydrogen.

Industrial & Regional Synergies

Each HVIC plays to its home team’s strengths:

- Odisha: Led by IIT Bhubaneswar with Hero Future Energies, Odisha Mining Corporation, Jindal Steel and Power and Dalmia Cement. They’re testing hydrogen injection in steel furnaces, running cement-kiln pilots and setting up captive power units.

- Gujarat: Zeroing in on export-grade derivatives like ammonia and methanol, tapping solar parks, fertilizer complexes and deep-water ports. MoUs are in the works with European and Middle Eastern offtakers.

- Kerala: Rolling out fuel-cell-powered harbour cranes, hydrogen-fired turbines for grid support and lean-burn trials in coastal shipping.

- Andhra Pradesh: Channeling green hydrogen into petrochemical and ammonia plants, testing pipeline blending and running techno-economic models for scale-up.

By matching local resources—minerals in Odisha, ports in Gujarat and Kerala, industrial parks in Andhra Pradesh—with real demand, these clusters become blueprints for broader industrial decarbonization.

Business & Policy Context

Under the National Green Hydrogen Mission (launched January 2022), India set aside ₹1 lakh crore for research, development and innovation, including ₹20,000 crore through DST’s competitive RDI Scheme. Grants from the Anusandhan National Research Foundation weave academic research into industry roadmaps.

Private players have already put in ₹315.43 crore, with top names from renewables, mining, steel and cement signing up—proof of solid industry buy-in. Each HVIC runs in a regulatory sandbox to trial tariff models, land-use norms and safety standards, feeding insights back into national guidelines.

The plan dovetails with Mission Innovation 2.0 and global efforts to slash electrolyzer costs and ramp up manufacturing. But it’s no small feat: hitting sub-$2/kg hydrogen costs means locking in stable renewable tariffs, fast-tracking approvals and securing reliable water sources that don’t conflict with farming. On top of that, skill building and SME support will be critical.

Community & Skills Development

Because tech alone won’t cut it, the HVICs include hands-on training. In partnership with the National Skill Development Corporation, new vocational centres will certify over 5,000 technicians in electrolyzer upkeep, hydrogen handling and fuel-cell integration by 2027. IIT Bhubaneswar and other university partners will host labs for advanced catalysts and digital controls, with a special push to involve women and local communities. The aim? Grow a skilled workforce ready to drive India’s green hydrogen revolution.

Global & Export Potential

With strategic port access in Gujarat, Kerala and Andhra Pradesh, these HVICs are poised to become export hubs for clean ammonia and liquid hydrogen. Early talks with European and Middle Eastern utilities are already lining up long-term offtake deals. Pairing green ammonia plants with coastal clusters means India could ship carbon-free fuel or fertilizer to demanding markets. By 2030, India could grab 10–15% of the global green hydrogen export pie, unlocking fresh forex streams and boosting energy diplomacy.

Collateral Impacts & Future Outlook

The HVIC rollout is set to create thousands of jobs, spur domestic manufacturing of electrolyzers and fuel cells, and chop up to 1 million tonnes of CO₂ annually once fully running. It’ll also speed up R&D-to-industry spin-offs and deepen public-private collaboration.

- Over 10,000 direct and indirect jobs across R&D, construction and operations

- 30–40% reduction in equipment costs within five years

- New export revenue streams from green hydrogen derivatives

- Validated regulatory frameworks ready for national scale-up

Over the next 18–24 months, everyone’s eyes will be on capital efficiency, operational reliability and market uptake as these clusters move from pilot to demo scale. If Odisha’s steel trials or Gujarat’s ammonia exports hit the right notes, they could become templates for 20+ more valleys by 2030. And if the cost curves bend as planned, these green hydrogen hubs won’t just decarbonize Indian industry—they’ll cement India’s spot as a global clean-energy leader.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.