How ‘Breathing’ Oxide Crystals Could Transform Fuel Cell Technology

August 19, 2025A Breath of Fresh Innovation

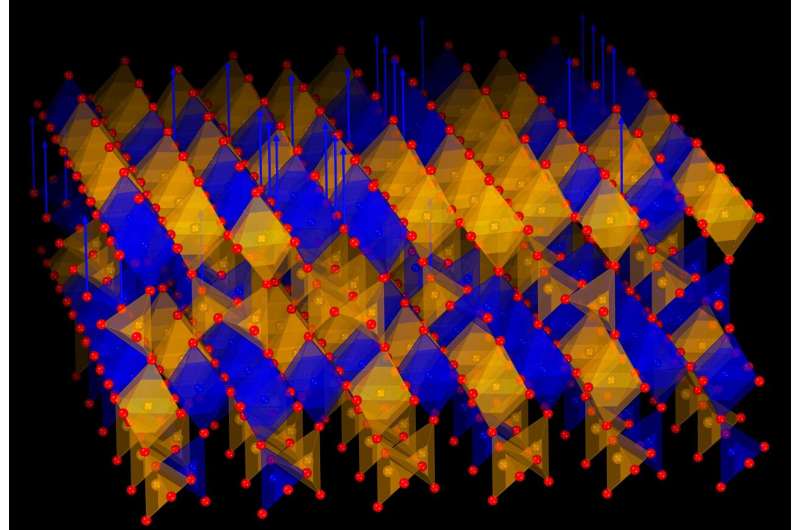

Ever thought a crystal could actually “breathe”? Sounds like something straight out of sci-fi, right? But that’s precisely what Pusan National University’s Hyoungjeen Jeen and Hokkaido University’s Hiromichi Ohta have been up to. Back in August 2025, they unveiled their work on a funky metal oxide—nicknamed SrFe0.5Co0.5O2.5—in Nature Communications. Picture a lattice of atoms that slurps in oxygen one moment and exhales it the next, just by tweaking the heat or the gas around it. This little molecular dance could completely shake up fuel cell technology, unlocking lighter, cheaper, and tougher fuel cells as we race toward a greener, zero-emission technology future.

The Core Discovery: Low-Temp Oxygen Breathing

Here’s the juicy part: crank the heat to about 400 °C and the crystal lets go of oxygen. Cool it down or swap in a different gas, and it soaks oxygen right back up. What’s wild is you can do this back-and-forth hundreds of times with barely a hiccup in performance. Sure, 400 °C still sounds scorching—but conventional solid oxide fuel cells (SOFCs) typically demand north of 800 °C to shuttle oxygen ions through their ceramic membranes. That higher heat means bulky insulation, ironclad seals, and steel shells—adding weight and ballooning costs. Our perovskite-based oxide slashes that thermal bill nearly in half, promising both energy savings and sleeker designs for tomorrow’s systems.

Why Oxygen Control Matters

Think of a fuel cell like a car engine: oxygen is your air intake, and you need just the right amount. Too little, and you’re gasping; too much, and you’re burning through fuel. Slide this breathing crystal next to the electrolyte, and voila—you’ve got a self-regulating oxygen tank built right in. It’s like having an adaptive snorkel that puffs open or pinches closed depending on how fast you’re paddling.

But wait, there’s more. The team sees this material doing double (and triple) duty:

- Thermal Transistors that flick heat on or off—imagine electronics that cool themselves when things heat up.

- Smart Windows coated with a thin film that tweaks its heat flow on demand, slashing building energy bills.

While the headlines are all about hydrogen fuel cells, the real excitement lies in a broader lineup of sustainable energy gadgets desperate for precise thermal management.

Decades in the Making

Believe it or not, scientists have been chasing a lower-temp SOFC dream since the 1990s. Early runs with doped zirconia and ceria looked promising but cracked under repeated heating cycles. Metal-organic frameworks (MOFs) strutted onto the scene with tunable pores, only to wilt in humid conditions or fall apart after just a few breaths. Then came perovskite oxides—materials famous for their oxygen vacancies that help ions move. The catch? Most either couldn’t keep going cycle after cycle or still required sky-high activation temperatures. That’s why SrFe0.5Co0.5O2.5 feels like the missing puzzle piece: it blends low-temp operation with rock-solid durability.

Cross-Border Collaboration

This breakthrough also highlights a pretty sweet partnership between South Korea and Japan. South Korea’s hydrogen roadmap and Japan’s Green Growth Strategy laid the groundwork for joint funding, shared labs, and even grad-student exchanges. Weekly Zoom calls, twice-yearly workshops—these teams became virtual neighbors. It’s a prime example of how international teamwork can speed up industrial decarbonization and bolster regional energy security.

Policy and Market Drivers

Around the world, interest in hydrogen production and hydrogen fuel cells is spiking. South Korea’s “Hydrogen Economy Roadmap” is shooting for 6.2 million fuel cell vehicles by 2040; Japan aims for 800,000 FCVs by 2030 under its Basic Hydrogen Strategy. Europe’s NextGenerationEU fund is pouring billions into fuel cell R&D, too. But lofty goals only work if the stacks hold up economically. Lowering operating temperatures trims raw material costs, eases thermal stress, and stretches maintenance intervals—critical ingredients for scaling up. Plus, factories can tweak existing sintering lines rather than revamping for ultra-high temps, speeding up adoption and nudging hydrogen ever closer to mainstream status.

Comparisons with Other Technologies

Before this new perovskite stole the show, doped ceria and zirconia variants led the low-temp race—until moisture or phase shifts knocked them out. MOFs teased room-temp action but buckled under the harsh chemistry of a working cell. In contrast, SrFe0.5Co0.5O2.5 strikes a sweet spot: strong oxygen-ion conductivity, chemical toughness, and an activation temperature that today’s industry rigs can handle.

The Ripple Effects in Energy and Beyond

Imagine what this means for the bigger picture. Stationary SOFC systems could finally compete with diesel generators in data centers, factories, or microgrids—no more wrestling with major thermal headaches or crazy upkeep. On the road, hydrogen trucks and buses could shed insulation bulk and weight, bumping up their range and driving down sticker prices. And in skyscrapers, “smart windows” could literally breathe heat in and out, trimming peak cooling and heating loads. These advances would give a serious boost to global sustainable energy targets.

From Lab to Industry

Turning a few grams of lab-grade crystal into tons of commercial feedstock is no walk in the park. Right now, the team’s fine-tuning sintering recipes, scaling production, and stress-testing performance under real-world conditions. They’ve already filed patents and are chatting with electrolysis and fuel cell manufacturers eyeing the next wave of fuel cell technology.

“There’s real momentum now,” Jeen says in an email. “Our immediate hurdle is replicating these results in pilot-scale modules.” Ohta adds that window and electronics makers are already knocking on their door, keen to experiment with smart-material coatings.

Looking Ahead

It’s easy to slap “breakthrough” on every lab find these days, but this one feels different. By bridging the gap between top-notch performance and lower operating temperatures, SrFe0.5Co0.5O2.5 could genuinely upend how we think about zero-emission technology—from stationary power to transport and beyond. If scale-up snags get ironed out, we might be staring at a domino effect: cleaner power plants, practical hydrogen vehicles, and everyday gadgets that adapt thermally to our needs. Next time you picture a crystal, imagine a living, breathing ally in our push for a cleaner future.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.