Hydrogen Embrittlement Visualized: 3D X-ray Imaging Breakthrough for Stronger Alloys

September 10, 2025Ever See Atoms in Action?

Have you ever wondered why our hydrogen-powered future seems so close, yet pipelines, tanks and turbines keep buckling under pressure? Here’s the kicker: hydrogen can slip into metal like a stealthy ninja, corroding from the inside out. Until now, we only saw the aftermath—snapped beams, split alloys, sudden failures. But a powerhouse crew from University of Oxford, Brookhaven National Laboratory, Argonne National Laboratory and University College London decided to catch hydrogen red-handed. By leveraging Bragg Coherent Diffraction Imaging at Argonne’s Advanced Photon Source, they shot the very first 3D movie of hydrogen mingling with stainless steel defects in real time. No kidding, this is a breakthrough that could rewrite the playbook for green hydrogen technologies!

Why We Needed This Breakthrough

If you’re in materials science, you’ve heard of hydrogen embrittlement—that ominous phrase that’s haunted engineers for decades. We’ve known hydrogen atoms creep into metal lattices, turn smooth dislocations into fracture factories and make top-grade steels like 316L brittle when exposed to hydrogen-rich environments. Yet, until now, our insights came from after-the-fact tests, ex-situ analyses and fancy theoretical models. Sure, we could predict probable breakpoints, but we had zero visibility into how the damage started. Thanks to reports on Phys.org and EurekAlert, we now know this is the first time anyone’s actually watched hydrogen reshape steel’s inner architecture live—down to the nanometer!

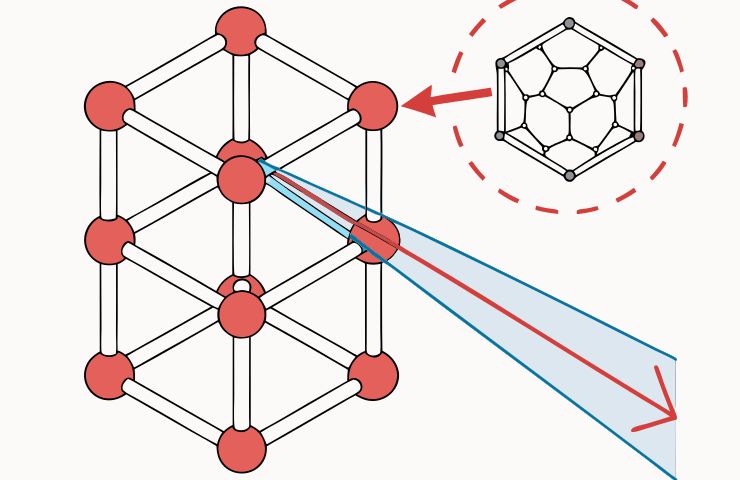

The Magic Ingredient: Bragg Coherent Diffraction Imaging

Picture a 3D X-ray microscope—your ultimate peek inside a single grain of steel. That’s the power of Bragg Coherent Diffraction Imaging. At the heart of U.S. synchrotron science, the Advanced Photon Source fires a razor-sharp, coherent X-ray beam at a nano-to-micrometer-scale grain in the metal. As those rays scatter off crystal planes, detectors pick up ghostly diffraction halos. Then, high-powered computations morph those halos into a vivid 3D strain map showing every nook and cranny of defects. The cherry on top? Researchers can pump hydrogen gas over the sample, pause the beam, and watch those imperfections shift, climb and relax—slice by slice—in stunning, real-time detail.

Moments That Made Us Gasp

Here are the jaw-dropping highlights from the 3D X-ray imaging sessions:

- Persistent dislocation mobility: With hydrogen at play, those dislocations glided—and even climbed—out of their usual planes at room temperature. Normally, you’d need extreme stress or heat for that stunt.

- Hydrogen elastic shielding: Hydrogen atoms huddled around defects, forming an invisible buffer that dampens local strain fields like a pro.

- Stress relaxation: Tiny pockets of intense stress simply eased up under hydrogen exposure, giving us an early warning of weakening long before any visible cracks appeared.

What Makes It a Big Deal?

This breakthrough isn’t just a neat party trick—it’s the blueprint for crafting hydrogen-resistant alloys that laugh in the face of embrittlement. Imagine pressure vessels, pipelines, refueling stations and fuel-cell stacks built from steels engineered at the atomic level to shrug off hydrogen attack. The benefits? Massive:

- Skyrocketed safety, with far fewer surprise failures.

- Slash-and-burn maintenance budgets for hydrogen infrastructure.

- Speedier material qualification, giving engineers confidence in long-term performance.

Beyond Lab Curiosity: Real-World Impact

This isn’t just nerdy imaging—it translates directly to industry. Check it out:

- Pipelines: National hydrogen distribution grids can opt for embrittlement-resistant steels, cutting leak risks across thousands of miles.

- Storage vessels: Designers of high-pressure tanks for trucks, ships and aviation fuel systems now have hard data to choose alloys that won’t crack during fill cycles.

- Aerospace & heavy machinery: Jet-engine components and turbine fixtures exposed to hydrogen-rich fuels can finally get a material upgrade path.

Collaborators Driving the Future

This kind of leap only happens when brilliant minds join forces:

- Prof. Felix Hofmann at University of Oxford, the go-to guru on hydrogen embrittlement.

- Dr. David Yang at Brookhaven National Laboratory, wizard of advanced X-ray imaging.

- Argonne National Laboratory, home to the world-class Advanced Photon Source.

- University College London, connecting raw data dots to real-world engineering predictions.

Backed by the U.S. Department of Energy and top-tier facilities, this collaboration marks a milestone in materials science.

Strategic Takeaways

Let’s zoom out and see the big picture:

- Funding & policy: DOE’s investment in synchrotron science turbocharges breakthroughs vital for clean energy.

- Academic-industry link: These partnerships ensure discoveries speed from journal pages to steel mills.

- Global race: Nations chasing hydrogen leadership can now set embrittlement-tested alloys as their benchmark.

Next on the Horizon

The team isn’t hitting pause any time soon. Up next:

- Mapping other critical defects—think grain boundaries and pesky inclusions.

- Putting full-scale components through their paces under real-world pressures and temperatures.

- Embedding atomic-scale insights into industrial simulation platforms.

- Teaming up with steelmakers to prototype the next generation of hydrogen-resistant alloys.

Ready to Rethink Hydrogen?

Whether you’re in engineering, policy or materials development, now is your time to jump in. Ditch the back-of-the-envelope guesses—embrace atomic-level insight. Let’s build hydrogen infrastructure that’s not just green, but tough as nails. Buckle up!

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.