Hydrogen Fuel Cell Trucks: Intelligent Energy’s 200kW Breakthrough

September 2, 2025Breaking New Ground in Heavy-Duty Transport

Ever daydreamed about trucks fueled by nothing but hydrogen and air? Well, pinch yourself—it’s real. On September 3, 2025, Intelligent Energy unveiled a 200kW heavy-duty fuel cell system built especially for hydrogen fuel cell trucks and buses. Straight out of Project Archer, this isn’t a pie-in-the-sky demo—it’s road-ready. Imagine swapping your old diesel engine for a compact unit that slips into the same chassis. No gutting the whole vehicle. The buzz hit full throttle at the Cenex Expo in Millbrook—England’s playground for automotive R&D and low-carbon trials. Industry vets got hands-on, and the reaction was unanimous: silent but seriously powerful. It’s a real showcase of what the UK supply chain can pull off when public funding and private smarts team up.

Why It Matters

Diesel rigs are responsible for about a quarter of the UK’s transport emissions—and a hefty chunk worldwide. They’re loud, thirsty for fuel, and spew out CO₂ and NOx like there’s no tomorrow. Hydrogen fuel cells have promised cleaner hauls, but three big obstacles stood in their way:

- Cost: Early setups were wallet-busting expensive per kilowatt.

- Complexity: Control modules were clunky and a pain to integrate.

- Safety: Hitting ISO 26262 functional safety standards proved tricky.

Project Archer says enough is enough. This new system trims expenses with a proprietary stack design, streamlines installs via a beefed-up ECU, and checks every safety box. That’s a triple win.

The Tech Behind the Power

So, what’s powering this revolution? Three headline ingredients:

- Proprietary Hydrogen Fuel Cell Stacks by Intelligent Energy. Their in-house design wrings max power from each kilo of hydrogen, outputting only water and a touch of heat.

- XCU8 Electronic Control Unit (ECU) from GEMS Performance Electronics. Built on the EM80-M platform, it juggles power delivery, tracks hydrogen flow, and locks down security for ISO 26262 certification.

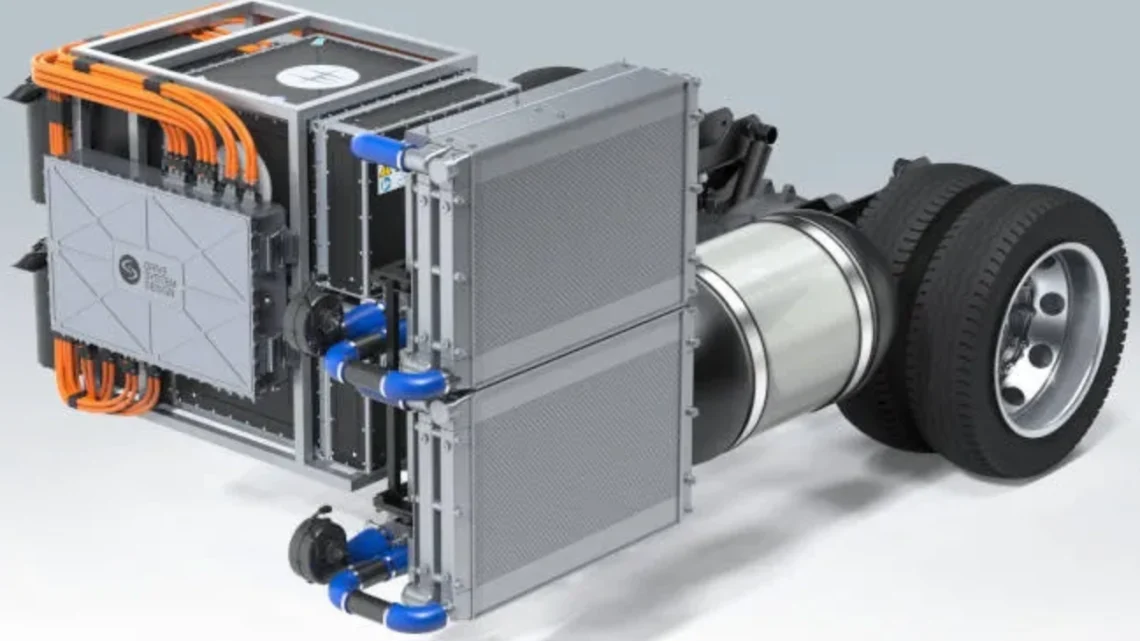

- 300kW DC-DC Converter by Drive System Design. It merges outputs from two stacks, balances voltage and current, and uses AC electrochemical impedance spectroscopy for live health checks.

All of it tucks into a compact package that slides right into a truck or bus bay—no extra chillers required.

Real-World Testing

This didn’t stop at the show floor. At Millbrook’s proving ground, demo vehicles are clocking full test cycles. Engineers run them through urban stop-starts, long-haul stretches, and hill climbs. So far, they’re holding steady at 200kW in scorching heat or sub-zero cold, with a target range of 300–400 miles per fill-up.

Policy and Funding Fuel the Race

Of course, none of this happens without a little push from policy and grants. The UK Advanced Propulsion Centre (APC) has matched industry dollars for Project Archer, fast-tracking R&D while keeping the IP in the UK. It lines up perfectly with the nation’s net-zero by 2050 ambition and its national Hydrogen Strategy.

Shaping the UK’s Clean-Tech Ecosystem

This effort is more than a single product—it’s a growth engine. From membrane fabricators to ECU software outfits, UK suppliers stand to benefit. We’re talking new assembly lines in historic engineering towns, hundreds of skilled jobs, and university partnerships that train tomorrow’s fuel cell experts.

Next Steps: Commercial Trials

With controlled demos wrapped up, mid-2026 is slated for trials with major UK fleets—logistics companies, bus operators, and waste services. Real-world data on uptime, fuel economy, and driver feedback will fine-tune everything ahead of a full commercial launch.

Looking Down the Road

This isn’t just upgrading the status quo—it’s a game-changer. Governments and OEMs around the world are paying attention. If Project Archer nails it, we could see hydrogen fuel cell trucks hauling cargo coast-to-coast by decade’s end. Time to say goodbye to the diesel haze—the hydrogen era for heavy-duty transport is here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.