Hydrogen Fuel Cells Achieve New Performance with Nitrogen-Doped High-Entropy Catalyst Exceeding DOE Targets

August 15, 2025Believe it or not, a nitrogen-doped, high-entropy intermetallic catalyst has just raised the bar for heavy-duty hydrogen fuel cells, smashing the U.S. Department of Energy’s performance and durability goals.

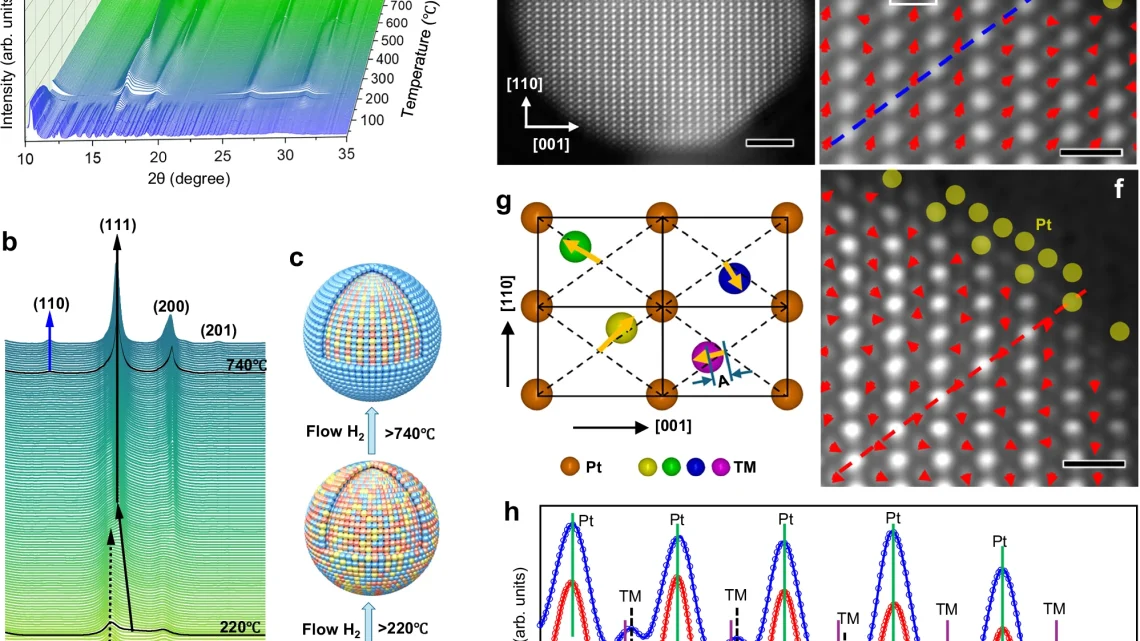

A global squad led by Xueru Zhao, Hao Cheng and Lijun Wu—backed by teams in China, the U.S. and Japan—published a game-changing paper in Nature Communications. They crafted an L10-ordered, nitrogen-infused high-entropy intermetallic catalyst, dubbed N-HEI/KB, blending Pt, Co, Ni, Fe and Cu. Under real heavy-duty vehicle PEMFC conditions, it delivered an oxygen reduction reaction (ORR) current density of 1388 mA cm⁻² at 0.7 V after 90,000 cycles—comfortably topping the DOE’s 1300 mA cm⁻² target.

How the Catalyst Works

What’s the magic? It’s all in mixing crazy-high configurational entropy with atomic-level craftsmanship. By slotting five transition metals into an ordered L10 lattice and peppering interstitial sites with nitrogen, the team squeezed sub-angstrom tensile strains onto Pt atoms. These tiny tweaks tune the electronic structure for faster ORR kinetics, while strong TM–N bonds hold the metals in place and curb dissolution. Advanced microscopy and spectroscopy showed particles staying under 2 nm even after marathon cycling—no clumping or performance drop-offs like you see in commercial Pt/C catalysts.

Strategic Implications

Hitting those DOE benchmarks isn’t just a toothpaste commercial—it’s a milestone for industrial decarbonization of freight transport. Long-haul trucks and buses crave catalysts that can handle brutal current densities, wild temperature swings and thousands of hours on the road. With its twin wins in activity and durability, N-HEI/KB promises to stretch catalyst life and cut swap-out costs, helping fleets close the gap on diesel in total ownership expenses. For OEMs and fleet managers, that’s a real nudge toward cost parity and a greener bottom line.

Looking Ahead

There’s still ground to cover before this leap lands in mass production: scaling up multi-element intermetallics by the ton, locking down critical metal supplies and fine-tuning quality control. But thanks to entropy-driven stability, atomic strain engineering and dopant pinning, we’re piecing together a toolbox of robust PEMFC catalysts. This breakthrough could supercharge the next wave of fuel cell technology, keeping the hydrogen truck revolution on track. To everyone rooting for sustainable energy, seeing this level of real-world validation under HDV duty cycles is a genuine confidence boost for hydrogen fuel cells’ role in decarbonizing heavy transport.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.