Hydrogen fuel cells: Atomic scan reveals gallium boost catalyst durability

September 16, 2025Imagine this: you’re peeking inside a catalyst and watching atoms dance and disappear right before your eyes. That’s exactly what a team from KAIST in Daejeon pulled off, teaming up with experts at Stanford University and Lawrence Berkeley National Laboratory. Professors Yongsoo Yang and Eun-Ae Cho used cutting-edge imaging to stitch together 3D atomic maps of platinum-nickel catalysts and found that a pinch of gallium can seriously boost their lifespan in working hydrogen fuel cells.

Launched in March 2025, this study zeroes in on a nagging issue that’s dogged proton-exchange membrane fuel cells (PEMFCs) since their debut in the 1990s. Platinum catalysts are powerhouses for the oxygen reduction reaction, but over time they get beat up—nickel leaches out, particles reshape, and structural strains relax. Until now, getting a front-row seat to these changes inside a live electrode—without wrecking your sample—was out of reach.

Breaking the atomic barrier

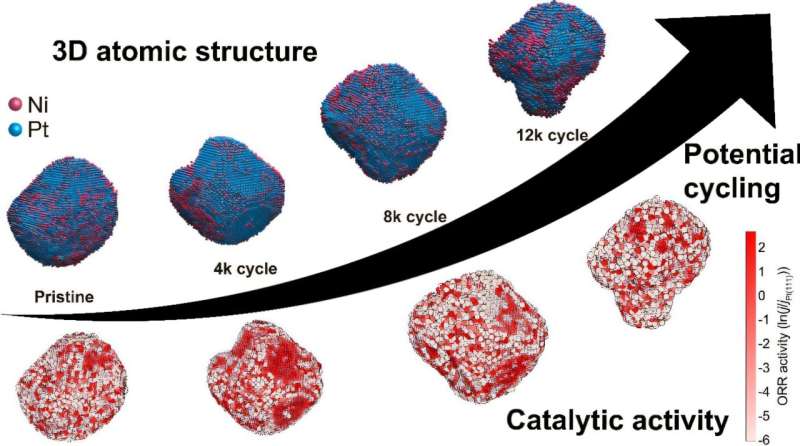

The secret sauce is Neural Network-Assisted Atomic Electron Tomography (AET), which blends high-angle STEM tilt-series shots with AI-driven reconstructions. The team snapped over 200 images, rotating the sample ±70°, then leaned on a U-Net convolutional neural network to scrub out noise and distortions. The payoff? Sub-angstrom (≈1.5 Å) 3D maps with about 2% compositional accuracy. By lining up images from fresh samples and those cycled 12,000 times under real fuel cell stress, they watched Pt, Ni and Ga atoms migrate, cluster or vanish.

The gallium edge

Armed with these atomic “movies,” the researchers spiced up PtNi nanoparticles with gallium doping and spotted three standout perks:

- Shape fidelity: Gallium locks onto octahedral facets, stopping particles from rounding off and losing surface area.

- Alloy integrity: Nickel dissolution slows way down, so the Pt-to-Ni ratio crucial for the oxygen reduction reaction (ORR) stays intact.

- Strain preservation: The beneficial lattice strains that speed up reactions stick around much longer compared to undoped particles.

When they ran performance tests, gallium-doped samples kept about 96% of their ORR activity after 12,000 cycles—versus roughly 83% for the undoped versions—a near quadrupling of resistance against degradation.

Market and policy implications

All this matters big time as green hydrogen and hydrogen production via electrolysis scale up, thanks to falling renewable costs and policies like the EU’s Fit for 55 and the US Inflation Reduction Act. Longer-lived catalysts slash both capital and operating expenses for fuel cell electric vehicles (FCEVs) and stationary units. Fleet operators could see total cost of ownership drop by up to 30%, while heavy-duty trucks, port machinery and backup generators benefit from quicker refueling and higher uptime. On top of that, stretching catalyst life cuts down platinum demand over the next decade—easing stress on mining and recycling streams and ticking the box on broader sustainable energy and industrial decarbonization goals.

Comparing catalyst strategies

Sure, folks have tried gold coatings or cerium alloys to stabilize catalysts, but those fixes often drive costs up or add complexity. By contrast, gallium is abundant, cost-effective and slides right into existing PtNi production, making it an easy scale-up play.

A renaissance in materials science

Beyond just hydrogen fuel cells, this neural network–powered AET is poised to shake up nanomaterials research across the board. Teams are already using it to track lithium-ion battery electrode cracking, watch solid oxide fuel cell layer breakdowns and study catalyst sintering in petrochemical setups—essentially delivering a universal atomic-scale check-up.

Looking ahead

So what’s next? The KAIST crew is aiming to capture AET data in real time, operando style—imaging catalysts under actual flow and thermal conditions. They’re also eyeing multi-element co-dopants, core-shell tweaks and surface treatments to push performance even further. Major automakers and energy firms are lining up pilot programs to slot gallium-doped catalysts into commercial stacks with an eye on a 2030 rollout. Plus, they’ve published every AET dataset and reconstruction algorithm in an open-access repository, handing labs worldwide the keys to replicate and build on their work—fast-tracking innovation across the fuel cell technology landscape.

At the end of the day, peeling catalysts apart atom by atom isn’t just a neat party trick—it’s a game-changing way to spot and solve durability issues. With gallium doping and AI-driven imaging tools in our toolkit, the future of hydrogen fuel cells has never looked more solid. If a picture is worth a thousand words, this one might just power tomorrow’s clean energy revolution.

source: phys.org

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.