Hydrogen Fuel Cells Gain Stability with Twisted-Blade Rotor for Roots-Type Pumps

November 25, 2025A Bumpy Road to Smooth Hydrogen Flow

Ever hit a pothole and wished your commute was smoother? Believe it or not, engineers face the same headache when pumping hydrogen in hydrogen fuel cells. The pumps that shuttle H2 through a fuel cell stack can spring tiny but painful surprises—sudden pressure spikes and flow swings that feel like invisible speed bumps. Those micro-shocks don’t just rattle the system; they drag down performance, shorten component life, and even raise safety concerns when you’re pushing above 1 MPa.

Zoom out, and those fluctuations translate into unplanned maintenance stops, warranty headaches, and higher costs for hydrogen buses, backup generators, and industrial electrolysis loops. It’s a reminder that even in the race toward sustainable energy, small hiccups can have big ripple effects.

A New Twist in Pump Design

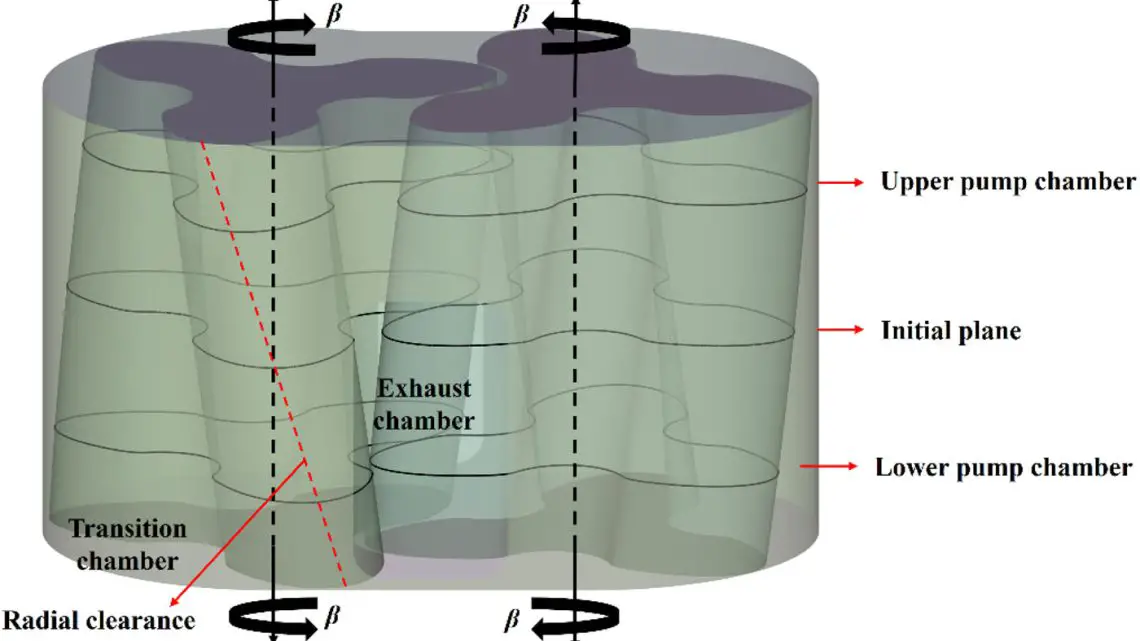

A peer-reviewed study in AIP Advances has dropped a neat hack on a century-old workhorse: the twisted-blade rotor for Roots-type hydrogen circulation pumps. Instead of straight, lobed rotors, these blades sport a gentle spiral—picture a paddle wheel with a twist. That simple geometry shift smooths out how the gas and rotor interact, slashing pressure and flow pulsations without upping energy use or killing volumetric efficiency. In plain English, you get the same pump output with way less jitter—huge news for anyone running fuel cell systems day in and day out.

Why Pulsations Matter

In a hydrogen loop, consistency is king. When H2 surges through a pump in chaotic bursts, it even throws off the delicate chemistry inside the cells, causes local hotspots, and accelerates mechanical fatigue. Over time, seals, bearings, and sensors wear out faster and you wind up with surprise downtime and ballooning upkeep bills.

Think of it like a drummer who can’t keep a steady beat—every note is off, and the whole performance collapses. For makers of fuel cell vehicles and stationary power providers, the aim is a rock-steady rhythm so the system hums along reliably every single day.

How the Twisted-Blade Rotor Works

Traditional Roots pumps have two counter-rotating lobed rotors that trap and move pockets of gas. Every engagement or disengagement creates a mini pressure hump. By twisting the blade profile, those humps slide past each other in a staggered dance, flattening the overall pressure curve.

It’s like choosing a smooth ramp over uneven stairs: you expend less effort, keep a steady pace, and avoid those jarring jolts. In pump-speak, that means fewer pressure peaks, a steadier flow, and no extra horsepower needed to get the job done.

Back in History

The Roots blower—pun very much intended—dates back to the mid-1800s, originally used to ventilate blast furnaces. Fast-forward to the clean energy era, and Roots-type pumps became a favorite in early fuel cell technology R&D because they’re simple, robust, and fairly efficient.

Over the decades, engineers have tried tip seals, variable-clearance tweaks, timing adjustments, and even downstream dampers, but the core pulsation challenge stuck around. Now, with global green hydrogen and clean ammonia initiatives ramping up, squeezing every ounce of reliability and performance from these pumps matters more than ever.

Business Context and Collateral Benefits

Reconfiguring production lines for a new rotor isn’t cheap. But fewer warranty claims, longer service intervals, and a lower cost per operating hour can make a compelling business case. Picture a fleet of hydrogen buses racking up miles between check-ups, or microgrid backup systems that kick in without missing a beat during a blackout.

Even better, retrofit kits could let operators ditch old rotors for twisted ones without overhauling the entire pump housing. That kind of upgrade path plays nicely with tight budgets and installation schedules, helping accelerate hydrogen infrastructure rollouts.

Parallel Efforts in Flow Optimization

This blade-twist joins a growing toolbox of tricks to tame internal flow dynamics. Advanced CFD simulations now let engineers watch gas behavior down to the microsecond, and optimization algorithms can fine-tune blade angles and clearances by microns. Some teams are even prototyping variable-geometry lobes that adjust on the fly to different load conditions.

Compared to heavy software workflows, the twisted-blade pitch stands out for its straightforward, hardware-first approach. No supercomputer required—you can see the benefits quickly on a test bench.

Field Validation and Next Steps

The researchers recommend a two-phase rollout: extended bench tests across a range of temperatures, pressures, and gas mixes, followed by pilot installs in prototype fuel cell vehicles or stationary power units. Real-world conditions—dust, vibration from neighboring machines, frequent cold starts—often reveal quirks that lab tests can miss.

Standards bodies like ISO and SAE may need to update guidelines to recognize new rotor geometries. Collaborative test campaigns involving pump makers, system integrators, and end users will speed up certification and market launch.

Challenges and Questions

Elegant as it is, the twisted rotor concept raises fresh puzzles. How will it handle rapid stop-start cycles or moisture and trace impurities common in distribution networks? Can existing pump casings tolerate shifted torque profiles without a redesign? Solving these questions calls for cross-disciplinary teamwork—from metallurgy to control systems.

And who knows? This tweak might inspire improvements in other positive-displacement machines beyond hydrogen circulation.

Looking Ahead

If all goes well, we could see twisted-blade rotors in commercial pumps within two to three years—right in step with broader drives for sustainable energy and zero-emission transport. Smoother hydrogen circulation means higher uptime for fuel cell vehicles, backup generators, and industrial processes.

Better reliability boosts investor confidence in hydrogen projects, which in turn fuels more R&D and strengthens the entire ecosystem. Sometimes, the biggest leaps in clean energy come from the subtlest twists—literally and figuratively.

The Ripple Effect on Decarbonization

At first glance, tweaking a rotor might not grab headlines in the race for clean ammonia or large-scale hydrogen production. Yet it underscores a vital truth: achieving full-scale industrial decarbonization hinges on optimizations at every level, from electrolyzer membranes to rotor geometry. Progress isn’t always about headline-grabbing breakthroughs—often, it’s the small turns that keep the machine humming day after day.

source: pubs.aip.org

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.