Hydrogen Fuel Cells: Intelligent Energy Unveils 200 kW IE-DRIVE HD for Heavy-Duty Vehicles

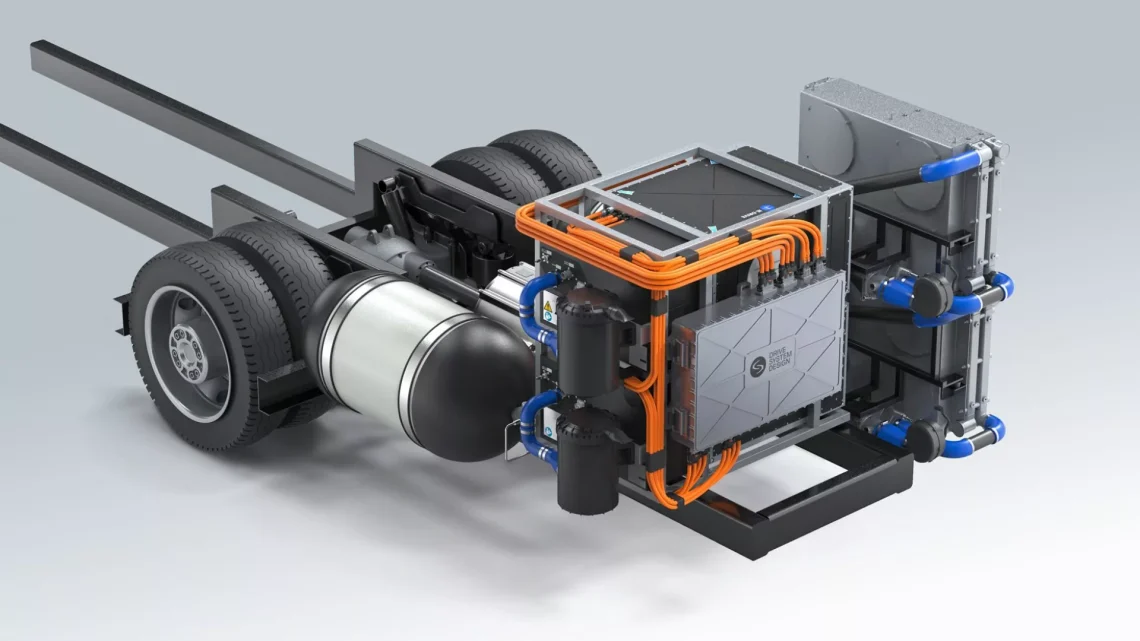

September 16, 2025When 1 September 2025 rolled around, Intelligent Energy sent shockwaves through the heavy-duty vehicle world by pulling back the curtain on the IE-DRIVE HD—a stackable, modular hydrogen fuel cell system that cranks out up to 200 kW net electrical output per unit. Introduced in the UK under the guidance of Dr. Ashley Kells, this newcomer sets a fresh milestone for integrated multi-stack configurations, making fuel cell technology a serious contender to diesel in trucks, buses and off-highway machinery.

Key features at a glance:

- 200 kW net output—blowing past the old 150 kW standard for multi-stack setups.

- The first-ever multi-input, multi-output DC-DC converter, letting each stack flex independently based on demand.

- Direct water injection cooling eats away at system weight and tosses bulky radiators to the curb.

- Our own airflow management channels guarantee even reactant distribution, even when you’re pushing hard.

- A modular, one-box design certified for road use, so OEMs can drop it in without a headache.

- Scalable architecture—link two, three or more units to ramp up to 400 kW, 600 kW or beyond.

Technical Blueprint and Innovation

The heart of the IE-DRIVE HD packs multiple polymer electrolyte membrane stacks into a single enclosure, all tied together by Intelligent Energy’s exclusive DC-DC converter. That converter juggles power from each stack, spitting out steady voltage to the drivetrain and allowing stacks to ramp up or down on the fly.

For thermal control, we went with direct water injection—a fine mist inside the system that keeps temperatures in check without the bulk of traditional cooling loops. On the airflow side, our patented channels spread air uniformly over each cell plate. That uniformity boosts performance, cuts hot spots and prolongs stack life.

Plug-and-play is more than a buzzword here. OEMs can bolt this one-box solution onto existing chassis, hook up hydrogen lines, electrical harnesses and coolant interfaces, and hit the road almost immediately—no major re-engineering needed.

Market and Policy Drivers

Heavy-duty road transport currently belches out about two gigatonnes of CO₂ a year—roughly 7% of global emissions. With EU and UK targets tightening for 2030 and beyond, fleet operators are scrambling for a Plan B. While battery-electric powertrains shine for city deliveries, they struggle under long-haul loads or in remote work zones. Uneven charging infrastructure and lengthy downtime can eat into profit margins.

That’s where hydrogen fuel cells like the IE-DRIVE HD come into play: you refuel in minutes—just like diesel—and you’re back on the clock. A 200 kW system can push a truck well over 500 kilometres depending on load and cycle, translating to more trips and fewer idle hours. Even better, hydrogen itself is versatile: from green hydrogen via electrolysis to blue hydrogen with carbon capture, or even emerging bio-based routes, you’ve got options to fit your supply chain.

“We’re seeing real excitement from OEMs and fleets ready to test high-power fuel cells,” says Dr. Ashley Kells. “The IE-DRIVE HD bridges that gap between lab demos and certified, road-ready systems. It tackles the real-world challenge of decarbonizing long-haul and off-road transport without giving up productivity.” The project got a boost from the UK’s Advanced Propulsion Centre via the ESTHER programme, with collaboration from Changan R&D Centre, Lyra Electronics and Alexander Dennis.

Evolution of Heavy-Duty Fuel Cells

Fuel cell technology has been around for over 50 years, but heavy-duty applications lagged behind because of size, cost and power constraints. Back in the early 2000s, truck and bus prototypes rarely cracked 100 kW—so batteries took the lead. Then in 2021, Intelligent Energy shook things up with a 150 kW stackable demo, proving modular designs could push boundaries.

Fast-forward to today, and at 200 kW per module, the IE-DRIVE HD raises the bar again. Sure, some rigs need a peak output near 582 kW, but by stacking two or three of these units, you can seamlessly hit 400 kW, 600 kW or more. It’s a smarter approach than designing one massive 600 kW stack: you cut down engineering time, build in redundancy and make maintenance easier—take one module offline, and the rest keep humming along.

Broader Impact and Next Steps

The rollout of certified, high-power, modular hydrogen fuel cells is set to turbocharge investment in hydrogen infrastructure. Refuelling stations will need upgrades to handle higher throughput and pressures, and producers and pipeline operators will see demand surge, driving down the cost of green hydrogen—key to making the total cost of ownership competitive with diesel.

Still, challenges remain. Green hydrogen needs to dip below about $3 per kilogram in target markets for operators to green-light a switch. Hitting that price tag means cranking up electrolyser manufacturing, tapping ever-cheaper renewable electricity, and slashing balance-of-plant costs—think power electronics, plumbing and sensors.

Intelligent Energy plans to ship IE-DRIVE HD modules to a handful of OEMs and fleet operators in late 2025, with wider commercial deployments rolling out in 2026. As fleets log real-world data on reliability, maintenance cycles and fuel efficiency, the industry will see whether hydrogen fuel cells can truly dethrone diesel in the toughest segments of logistics. For now, the bar’s been raised—and everyone’s watching to see if the IE-DRIVE HD delivers on the promise of zero-emission technology and sustainable energy solutions.

About Intelligent Energy

Founded in 2001 and based in the UK, Intelligent Energy designs, develops and manufactures fuel cell technology for automotive, aviation, stationary power and industrial markets. Backed by strategic partnerships and public innovation funds, the company has been a pioneer in modular, scalable fuel cell architectures driving the shift to zero-emission technology and a sustainable energy future.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.