Hydrogen Fuel Cells: Kyushu University’s Scandium Superhighway Lowers SOFC Temperature to 300°C

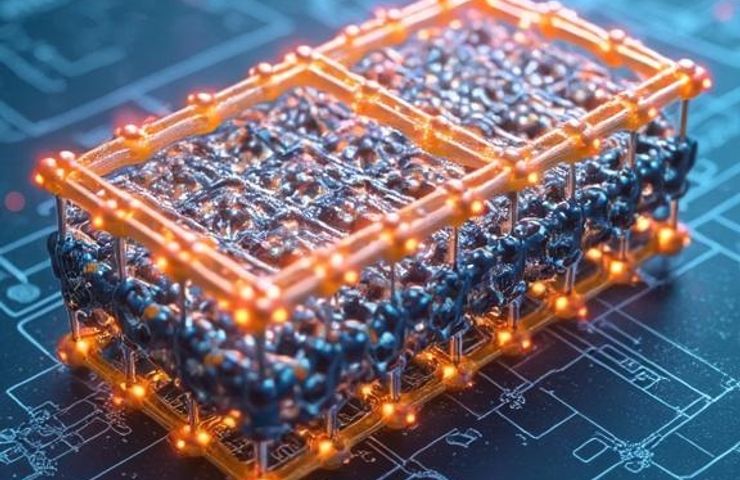

August 11, 2025Imagine dialing down a solid oxide fuel cell’s operating temperature from a blistering 800°C to a comfortable 300°C. You don’t need to be a materials geek to see why cutting out hundreds of degrees is a total game-changer. On August 8, 2025, a team led by Kyushu University in Fukuoka Prefecture, Japan, revealed a prototype SOFC that hums along at just 300°C. The secret? A scandium superhighway—a high-density network of Sc–O bonds in scandium-doped barium stannate and barium titanate ceramics that slashes the proton migration barrier and unlocks rapid proton transport. Published in Nature Materials and peer-reviewed, this breakthrough could drive down costs, shrink insulation needs, and broaden applications for hydrogen fuel cells across industries.

Technical breakthrough: the scandium superhighway

The secret sauce here lies in BaSnO₃ and BaTiO₃ electrolytes loaded with extra scandium. Instead of sitting idle, the scandium atoms line up into continuous ScO₆ chains—think express lanes where protons zip through with almost no resistance. Traditional SOFC electrolytes usually demand 700–800°C to hit similar proton conductivity, but this ScO₆ network, plus the natural “give” in the ceramic lattice, delivers efficient transport at 300°C. Lowering the temperature means you can ditch pricey interconnects, seals, and heavy insulation, cutting both up-front capital and ongoing operating costs.

Historical context and lingering challenges

Solid oxide fuel cells have been in the works for decades thanks to their high efficiency and long lifespans, but that extreme-heat requirement has been a stubborn speed bump. Early research leaned on zirconia-based electrolytes and dopants like yttria or lanthanum, yet none kept ions moving fast below 600°C. Scandium popped up as a conductivity booster years ago, but its premium price tag and scarce supply kept it stuck in the lab. By marrying scandium’s perks with barium-based perovskites, the Kyushu team finally vaulted over that thermal hurdle—opening the door to real-world scale-up. Still, securing a steady scandium supply and keeping costs in check remain on the to-do list.

Strategic implications for hydrogen fuel cells

Hitting that 300°C sweet spot isn’t just a neat trick—it reshuffles the deck for fuel cell technology. At these milder temps, manufacturers can swap exotic alloys and thermal-barrier coatings for everyday steel and affordable ceramics. That slashes capital expenses and speeds up startup times, making SOFCs practical for home combined heat and power units, backup generators, or even onboard power for trucks and ships. It also dovetails perfectly with Japan’s drive for carbon neutrality by 2050, showcasing a homegrown win in zero-emission technology. Globally, this could fast-track hydrogen’s role in heavy industry, data centers, and remote sites where reliability and low emissions are non-negotiable.

Outlook and remaining hurdles

We’re not out of the woods yet. First off, scandium is still a niche element, traded in tiny batches at premium prices. Scaling up its production—whether through aluminum refining by-products or new mining ventures—will be critical to keep costs down. Then there’s long-term stability: engineers need to prove these scandium-doped ceramics can endure the start-stop grind and real-gas environments over thousands of hours. The Kyushu team is already teaming up with industry partners to build larger test stacks and stress-test durability under grid-tied and vehicular conditions.

Conclusion: A new chapter for fuel cell technology

By carving out a scandium superhighway, the Kyushu researchers have shattered the old trade-off between high conductivity and high temperature in SOFCs. If they nail the supply chain and scale-up, we could soon see hydrogen fuel cells that are cheaper to build, faster to fire up, and fit for all kinds of roles—from clean backup power to decarbonized transport. It’s a reminder that sometimes the biggest leaps come from rethinking the materials under our feet, one atomic highway at a time.

About the research

These findings landed in Nature Materials on August 8, 2025, after a rigorous peer-review process. Leading the charge was Professor Yoshihiro Yamazaki at Kyushu University, backed by a multidisciplinary crew of ceramics specialists, electrochemists, and computational modelers. Supported by Japan’s Ministry of Education, Culture, Sports, Science and Technology, their work ties into global efforts around sustainable energy and industrial decarbonization, keeping us on track for a cleaner, zero-emission future.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.