Hydrogen Fuel Cells Take the Helm in Singapore’s Shipping Hub

August 25, 2025Marine shipping is still hooked on heavy fuel oil, churning out around 940 million tonnes of CO₂ every year. With the International Maritime Organization eyeing a 50% emissions cut by 2050, we’re going to need legit zero-emission technology to hit those targets. VINSSEN and Marinteknik shook hands on an MOU in Singapore that could upend the status quo. They’re rolling out a hydrogen-ready battery-based hybrid propulsion system—a plug-and-play solution you start out running as a diesel-hybrid and then seamlessly flip to full hydrogen fuel cells or battery-electric power when the ports are set up for green hydrogen bunkering. Of course, building it is one thing; proving it commercially at sea is a whole other ballgame.

Turning the Tide in Maritime Decarbonization

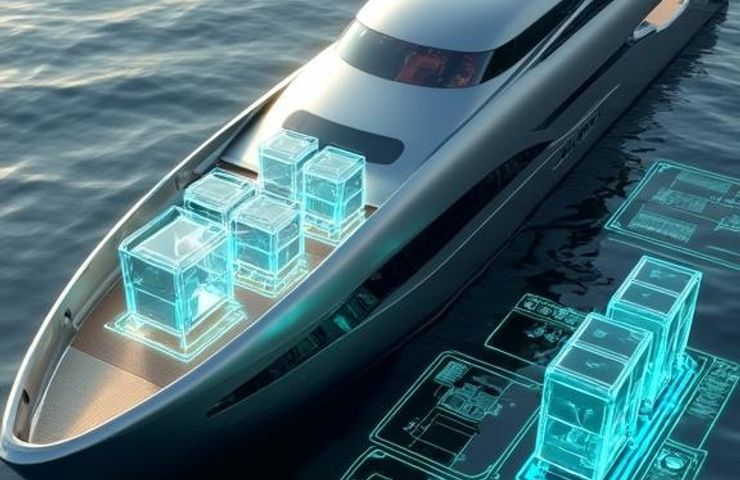

The MOU brings together VINSSEN—the South Korean crew behind Korea’s first AIP-certified hydrogen vessel and a type-approved 60 kW PEM fuel cell stack—and Marinteknik, Singapore’s trusted partner for vessel design and turnkey projects for over four decades. They’re pitching a super-modular setup: interchangeable fuel cell and battery pods, smart digital control units and a diesel genset as a backup. Captains can dip their toes in with diesel-hybrid mode, nail down performance on shorter routes, then plug in zero-emission modules as the hydrogen infrastructure evolves—no major engine-room remodel required.

Inside the Hybrid Powertrain

At its heart, the system blends three power sources: diesel gensets, battery banks and hydrogen fuel cells. VINSSEN’s cloud-based vessel management platform keeps an eye on power demands, route data and safety stats in real time. It juggles load between diesel and batteries to optimize cost and emissions, then flips to hydrogen cells for silent, zero-emission cruising when ports are ready to refuel with clean energy. Those AIP-certified 60 kW PEM modules hit peak efficiencies of up to 55% and pass all the marine vibration tests. Batteries handle peak loads, slashing genset time by about 40% in trials. And because everything comes in ISO container-sized skids, swapping modules during port calls is literally a plug-and-play job. Safety’s covered too: double-walled hydrogen tanks, fail-safe valves and next-gen leak detection wired into the digital brain—just what regulators want to see.

Playing the Long Game

This partnership isn’t just about hardware—it’s a strategic chess move. VINSSEN locks into Southeast Asia’s booming shipping scene, riding on Marinteknik’s deep ties with shipowners and regulators. Marinteknik, meanwhile, fast-tracks its foray into hydrogen propulsion without investing a fortune in R&D. Their rollout plan is smart: kick off with tugs and ferries, then scale up to offshore support vessels and smaller cargo ships. Each successful pilot builds confidence, nudging leasing companies and insurers to warm up to hydrogen’s risks. And with a regional push on sustainable energy, they’re betting that a 20% cut in fuel costs versus diesel-hybrids will seal early deals and set the bar for competitors.

Singapore: From Bunker Fuel to Hydrogen Hub?

Singapore handles more cargo than almost anywhere else—over 37 million TEUs a year—and it’s desperate to shake off heavy fuel oil’s nasty emissions. LNG bunkering’s already live, methanol trials are wrapping up, and electric ferries are on the water. Under the Maritime Green Plan 2030, the city-state wants green corridors linking it to Australia and Japan, aiming to slice up to 10 million tonnes of CO₂ in the next decade. The Maritime and Port Authority is dangling grants covering up to 30% of green tech capex, and the Economic Development Board is lining up anchor tenants for hydrogen bunkers. Hosting VINSSEN-Marinteknik pilots cements Singapore as a test-bed: ports fine-tune bunkering protocols, crews get honed on hydrogen-handling, and regulators draft real-world safety rules. Nail a 30% emissions cut with solid uptime, and this local MOU could become the blueprint for Jakarta, Shanghai or even Dubai.

The Real-World Hurdles

Don’t kid yourself—it’s not going to be smooth sailing. Green hydrogen production in Asia is still in its infancy, with electrolysis capacity clustered in a handful of mega-projects, so supply remains patchy. Building a pan-Asian network of high-pressure hydrogen bunkering stations will demand billions in hydrogen infrastructure investments and policy stability that outlasts election cycles. Onboard, those beefy tanks and safety systems eat into cargo space, and crews need rock-solid training; a leak demands split-second action. Regulators must sync up standards on bunkering, storage and emergency response across multiple jurisdictions—a legal and logistical maze. Cost is another pinch point: retrofitting hybrids with hydrogen gear runs 20–30% higher than diesel-hybrids. Operators will only take the plunge if carbon levies, subsidies or long-term fuel savings tip the scales. Until hydrogen fuel cells stack up on price, we could see adoption stall after a few flashy demos. Insurers are still guessing on hydrogen conversions too—steep premiums could push financing costs sky-high unless governments step in with guarantees.

Looking Over the Horizon

Let’s be real: this MOU isn’t going to sink fossil-fuel shipping overnight, but it’s a crucial pilot for unlocking zero-emission technology at sea. If VINSSEN and Marinteknik can prove they can deliver reliable, cost-effective service on Singapore’s busiest lanes, hydrogen might finally move from lab bench to mainstream shipping fuel. The trick? Ports, policies and purse strings all have to line up. Keep your eyes peeled for next year’s pilot results—they’ll show whether this dream of green hydrogen-powered shipping is set to become the new normal.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.