Hydrogen Infrastructure: Fukui Seisakusho and ClassNK to Develop Ultra-High Pressure Safety Relief Valves

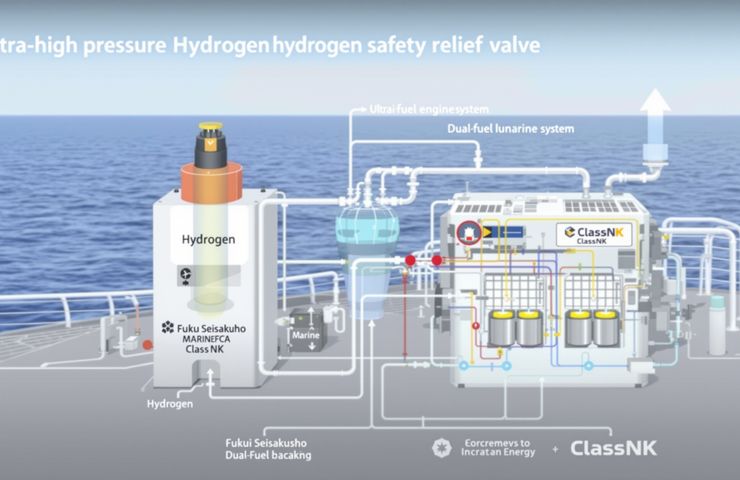

September 12, 2025At Gastech 2025 in Milan, Italy on September 9, 2025, there was a real buzz when Japanese valve maestros Fukui Seisakusho Co., Ltd. and maritime classification heavyweight ClassNK (Nippon Kaiji Kyokai) shook hands on a Memorandum of Understanding. They’re teaming up to co-develop RPS-type ultra-high pressure safety relief valves for hydrogen dual-fuel engines. It’s the natural follow-up to their 2023 effort on PILOT-type low pressure safety valves for liquefied hydrogen (LH2) carrier tanks—and a big win for building out robust hydrogen infrastructure that drives zero-emission technology in shipping.

Why It Matters

- It tackles the safety puzzles of moving hydrogen at scale, a must-do for any push toward sustainable energy and industrial decarbonization.

- Leverages Fukui’s engineering edge on valves and ClassNK’s gold-standard certification playbook.

- Aims straight at hydrogen embrittlement and high-pressure sealing—those are real showstoppers if left unchecked.

- Lines up with the IMO’s 2050 greenhouse gas goals by making hydrogen-powered vessels a practical reality.

- Could fast-track new bunkering sites and supply chain hubs at major ports worldwide.

Global Context

Globally, hydrogen’s making waves in shipping: more than 30 nations have rolled out national hydrogen strategies, and ports from Singapore to Rotterdam are testing out bunkering ops. And just at Gastech 2025, over 30,000 attendees got a front-row seat to this momentum. Still, handling hydrogen safely—especially under ultra-high pressure—remains the bottleneck holding back wider adoption.

Analysts are eyeing over 100 hydrogen-ready vessels by 2030, with contract value topping $50 billion. Major liners and chassis makers are kick-starting hydrogen propulsion projects, but scaling up hinges on having the right safety hardware locked in place.

Hydrogen in Maritime Transport: The Challenge

Hydrogen is a slippery customer: its tiny molecules slip through seals more easily, and over time they can turn metal brittle. Make no mistake—LNG-rated valves just don’t cut it for hydrogen’s quirks. Without dependable pressure relief solutions, shipowners face both safety headaches and regulatory red tape that stall progress on hydrogen dual-fuel engines.

To pack in as much energy as possible, hydrogen fuel systems often run at 200–350 bar. But even microsized weld pinholes can turn into big leaks. In one test, hydrogen diffused through stressed steel at rates ten times higher than methane—so it’s crystal clear we need rock-solid, leak-proof gear.

Engineering Innovations

The new RPS-type ultra-high pressure safety relief valves are built to pop open once pressures hit around 350 bar in hydrogen lines. Here’s how they’re engineered to deliver:

- High-grade alloys and special surface coatings that shrug off hydrogen embrittlement and corrosion.

- Precision-machined valve seats and dynamic O-ring seals that stay tight even as engine temps swing.

- Spring-loaded or pilot-actuated triggers tuned for rapid hydrogen venting, dodging dangerous pressure spikes.

- Modular build for easy servicing and the flexibility to fit different engine scales.

- Built-in sensors to keep tabs on seal health—think predictive maintenance to cut downtime.

Each valve prototype must endure over 100,000 pressure cycles with zero performance drop, tested from –40 °C to +60 °C to mimic everything from tropical routes to Arctic crossings. Once the design’s locked down, ClassNK will run its official type approval under the new rules for hydrogen fuel systems.

Strategic Outlook

This MoU plugs right into the IMO’s plan to slice shipping emissions in half by 2050. By pre-certifying these safety components, Fukui and ClassNK hope to shave months off retrofit and new-build timelines. Shipyards can pitch hydrogen-ready vessels with confidence, and financiers or insurers might even sweeten their deal terms when class-approved valves are on the spec sheet.

According to ClassNK’s upcoming “Rules for Hydrogen Fuel Supply Systems,” every component needs its own type approval. By front-loading valve certification, the partners are cooking up a blueprint that other manufacturers can follow—cutting duplicate testing costs and speeding up global standardization.

Japan’s early moves on hydrogen demos, teamed with the EU’s hydrogen roadmap and emerging Asian standards, are setting the stage for a worldwide market upswing. Industry insiders reckon hundreds of hydrogen-ready ships could be on contract by the early 2030s—translating into a multi-billion dollar pipeline for specialized gear and services.

On top of that, locking down class-approved valves can bring insurance premiums down by an estimated 10–15%. That reassured risk profile might encourage banks to back more hydrogen retrofits and newbuilds outfitted with certified safety systems.

From Past to Future

You could call this next chapter the sequel to the 2023 deal where Fukui and ClassNK got a PILOT-type low pressure safety relief valve (PSL-MD) certified for LH2 cargo tanks. That move tackled boil-off issues on hydrogen carriers and put them at the forefront of maritime hydrogen safety. Now, shifting the focus to engine-side valves wraps up the picture—covering everything from storage to transfer and combustion onboard.

Broader Impacts

Advances in these relief valves are bound to ripple across the whole hydrogen value chain. Tougher certification standards can nudge classification societies toward harmonized rules, avoiding a patchwork of regulations. You’ll see compressors, fuel lines, even storage tanks stepping up to meet the same rigorous benchmarks—raising the bar for hydrogen storage and equipment worldwide.

Since classification bodies often swap research insights, ClassNK’s protocols could steer future ISO or IEC standards for hydrogen fuel systems, boosting interoperability among gear makers and shipyards.

Plus, with lower technical risk, port operators may be more eager to roll out hydrogen bunkering, while producers of clean ammonia and green hydrogen find a clearer market path. That could tip investment away from LNG setups and tighten the window for fossil-based fuels in shipping.

Decarbonization Impacts

Shipping is responsible for about 3% of global CO₂ emissions. Swapping over to hydrogen dual-fuel engines, backed by reliable safety valves, could chop 15–20% of those emissions off the bat—and eventually hit zero if green hydrogen scales up. This collaboration directly tackles the safety puzzles that have slowed progress, pushing us closer to genuine zero-emission technology in maritime transport.

To put it in perspective, the average mega-container ship belches out around 60,000 tonnes of CO₂ each year. Even converting a slice of the world’s fleet to hydrogen dual-fuel could deliver massive cuts. Pair that with green hydrogen made via electrolysis, and you’re steering shipping toward net-zero operations.

On the Horizon

What’s next? Detailed engineering deepdives, prototype builds, and joint sea trials—possibly on a demo vessel in Japanese waters. Beyond that, they’re eyeballing cross-sector uses like hydrogen-driven offshore construction ships and harbor tugs. Early R&D hints those modular valves could double as the brain of onshore refueling stations, blurring the lines between maritime and land-based hydrogen infrastructure.

If testing stays on track, marine engine makers might snag valve certifications by late 2027, gearing up for commercial rollout in 2028. They’ve already penciled in R&D workshops for Q1 2026 at Fukui’s test center, pulling in everyone from engine OEMs to port operators.

About the Companies

Fukui Seisakusho has been a go-to name for industrial and maritime valves for decades, and they’ve recently steered into hydrogen applications. ClassNK stands tall as a leading maritime classification society, crafting safety and environmental standards that ships around the world rely on.

Sources: ClassNK press release; Safety4Sea; Riviera Maritime Media.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.