Hydrogen Pipeline: BMW’s Leipzig Plant Leads Automotive Decarbonization

October 1, 2025Leipzig’s been famous for centuries-old trade fairs and its vibrant cultural buzz—but nowadays it’s grabbing headlines for something entirely new: a big leap in green hydrogen infrastructure. Nestled in Saxony, this storied city is evolving into a cutting-edge center for automotive and energy innovation. By mid-2027, BMW Group Plant Leipzig will become the first car factory on the planet to tap pure hydrogen straight from a dedicated hydrogen pipeline—no trucking, no fuss. It might sound like corporate speak, but this is a genuine game-changer in automotive decarbonization, setting a fresh pace for sustainable manufacturing and fueling momentum across Germany’s booming hydrogen network.

A Major Milestone in Hydrogen Infrastructure

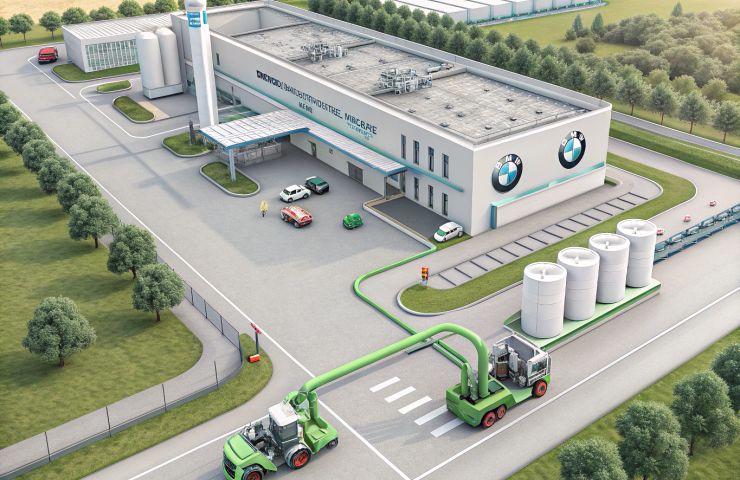

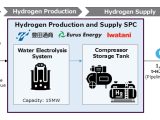

Here’s the scoop: rather than loading up tanker trucks day and night, BMW teamed up with Mitnetz Gas GmbH to build a sleek, two-kilometre underground pipeline. From there, Ontras Gastransport GmbH slides it straight into Germany’s national grid—bye-bye carbon-heavy trucking, hello reliable supply. Considering Germany’s aiming for nearly 9,000 kilometres of hydrogen arteries by 2032, Leipzig’s plant will enjoy a 24/7 feed of ultra-pure hydrogen. It also slashes logistical headaches and cuts the risk of road closures or weather delays throwing a wrench in daily operations. That means fewer delivery slots to juggle, lower transport costs, and a much smoother path to hit net-zero targets, plus cutting down the carbon footprint across the board.

And here’s the kicker: this isn’t low-pressure dribble—it’s high-pressure hydrogen regulated to the letter for quality and safety. That means when H₂ streams through the pipes into the plant, it’s instantly usable in burners, boilers, and fuel cells without a hitch. Engineers can dial in precise pressures and volumes, run performance tests, and map out efficiency gains in real time. All of this makes Leipzig the go-to living lab for Europe’s industrial-scale hydrogen distribution—and a blueprint for any factory dreaming of cleaner operations. Visitors and industry leaders are already coming by busloads to take notes, because the lessons learned here will shape future green hydrogen projects across the continent.

Elevating Production with Clean Energy

Inside the plant, a host of systems is primed for that clean hydrogen. In the paint shop, fuel-flexible burners switch from natural gas to hydrogen in seconds, cutting CO₂ and ensuring more consistent curing. Meanwhile, over 230 hydrogen fuel cell-powered intralogistics vehicles—Europe’s largest fleet—zip around the halls, hauling pallets and parts. Those trucks have been running since 2013, but the new pipeline lets BMW retire diesel and electric support vehicles, slashing both costs and emissions.

And don’t overlook the plant’s role in electric vehicle production. Since March 2024, Leipzig’s been cranking out fifth-generation EV battery packs—assembling, testing, and shipping them worldwide. The hydrogen-fed energy powers welding robots, assembly lines, and quality-control labs, trimming carbon at every step. It’s proof that you can mass-produce high-voltage batteries with virtually zero emissions.

Collaboration Fuels Progress

Pulling off something this bold takes more than just big machinery—it’s about the people, too. BMW Group is in lockstep with city hall, Saxony’s economic development office, and Germany’s Federal Ministry for Economic Affairs. They’ve hosted neighborhood briefings, stakeholder workshops on pipeline safety, and brainstorming sessions about future expansion—streamlining approvals, cutting red tape, and making sure locals feel heard. Word is, these playbooks are already inspiring chemical and steel plants to follow suit. It’s about building trust as much as pipelines, making every step a shared win.

This collaboration is a masterclass in public-private teamwork. When BMW’s manufacturing savvy joins forces with Mitnetz’s pipeline craftsmanship and Ontras’s grid operation expertise, you end up with a roadmap any sector can follow. Industry forums are already buzzing, and other factories—from chemicals to cement—are eyeing the playbook. That’s how you lead the charge: by gathering the right experts, aligning your goals, and powering ahead together.

Regional and Global Impact

Zoom out a bit, and this pipeline benefits way more than just the plant’s bottom line. Leipzig’s roughly 628,000 residents will welcome fewer tanker trucks rumbling through their neighborhoods—think less congestion, quieter streets, and better air quality for everyone. Local businesses will thank you for lighter traffic, too. For the plant itself, cutting trucked deliveries translates into a hefty reduction in Scope 1 and Scope 2 emissions, moving BMW closer to its target of slashing CO₂ per vehicle by 40% by 2030, while boosting community health and safety.

But the ripple effect stretches well beyond Leipzig. Hooking up regions with a 9,000-kilometre hydrogen highway strengthens Europe’s energy security and shields economies from volatile fossil fuel swings. Imagine factories in France, Spain, and Poland all tapping into the same green hydrogen backbone—industries from ceramics to cement asking, “Why aren’t we linked in?” That momentum could unleash billions in fresh investments, spark new R&D hubs, and churn out thousands of sustainable jobs, turbocharging the EU’s climate and industrial goals.

Cost Savings and Environmental Benefits

This isn’t just green cred—it’s a real boost to the bottom line. By ditching tanker trucks, BMW expects to save millions of euros over the next decade. Early data even points to a 20–30% drop in hydrogen procurement costs thanks to direct pipeline delivery and fewer handling fees. Those freed-up funds can plug right back into further decarbonization efforts—whether it’s expanding on-site green hydrogen production, R&D for next-gen fuel cells, or giving the factory more wiggle room in its operational budget.

On the emissions front, swapping trucks for pipes could cut logistics-related CO₂ and NOₓ by up to 50% per kilogram of hydrogen. Over hundreds of tonnes each year, that’s a serious dent in greenhouse gases and local air pollutants—translating to cleaner air for workers and neighbors alike. It’s the kind of impact that grows with every kilogram, keeping sustainability and savings on pace together.

A Glimpse Into the Future

Honestly, what thrills me most are the small-scale breakthroughs—a simple two-kilometre hydrogen pipeline that sparks a massive rethink of factory operations. It’s proof you don’t need a trillion-euro megaproject to drive change; often, it’s about the right connection at the right time. Leipzig’s been ahead of the curve since its i3 and i8 days, then went all in with Europe’s largest hydrogen intralogistics fleet. Now, that infrastructure is knitting every piece together into a lean, green machine.

To me, this isn’t just another plant upgrade—it’s a window into the future of manufacturing. Imagine next-gen fuel cells working alongside battery systems, cleaned up by green hydrogen at every step. If you ask me, we’re watching the blueprint for a new industrial era—one built on sustainability, resilience, and bold partnerships. And judging by the energy in Leipzig, this is just the opening act on our road to a truly net-zero tomorrow.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.