Hydrogen Production Breakthrough: KIER’s Carbon Cloth Electrode Powers 800-Hour Seawater Electrolysis

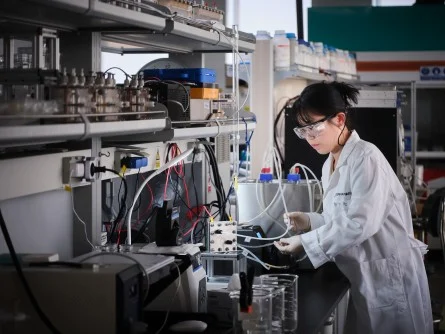

August 15, 2025KIER’s crew dropped their findings in Applied Surface Science, after demoing the new electrode at their Daejeon labs. They took a run-of-the-mill carbon cloth, gave it a hot bath in concentrated nitric acid to boost its water-loving properties, and created perfect anchor points for a ruthenium, cobalt and molybdenum catalyst mix. Then, they cranked it up at over 500 mA/cm²—on par with big industrial electrolyzers—and let it rip for 800 hours without so much as a hiccup in performance. Post-test checks showed no ruthenium or cobalt sneaking away into the electrolyte. In Dr. Han’s words, “Hitting that 800-hour mark without a hint of corrosion proves carbon cloth can outlast metal supports in brutal seawater.” Before this, most experiments blinked out after just a few dozen hours.

Technical Insights

What makes this tick is a custom acid treatment. The untouched carbon cloth goes for a deep soak in nitric acid, which roughs up its fibers and grafts on oxygen-rich groups. That turns the cloth into a super-wettable, porous scaffold. Next, they electrodeposit ruthenium nanoparticles all over that network, with cobalt and molybdenum slipping into the nooks to supercharge electron flow. Thanks to its microporous design, gas bubbles and ions zip away fast—essential for keeping things stable at high currents. And here’s the kicker: the catalyst load sits below 1 wt%, way leaner than the usual iridium or platinum hustle, slashing material costs. Electrochemical impedance spectroscopy and chronopotentiometry recorded about a 0.15 V drop in overpotential—roughly 25% better than benchmark seawater electrodes—translating into a 1.3× boost in energy conversion efficiency. ICP-MS scans afterward confirmed almost zero metal-ion leaching after those 800 marathon hours, proving rock-solid resistance to chloride assault.

Strategic Impact

Unlocking direct seawater electrolysis at this scale tackles two big decarbonization hurdles: freshwater scarcity and hydrogen cost. South Korea, with its tight water supplies, has already set its sights on 26.4 GW of electrolyzer capacity by 2030. This new electrode plugs right into planned coastal and offshore wind farms, letting modular electrolyzers hook straight up to renewable power. By minimizing precious-metal inputs, it slashes CAPEX and leans on the ocean’s infinite feedstock, trimming both water and catalyst supply-chain worries. The ripple effects are huge—from marine shipping whipping up zero-emission fuel on the move, to coastal refineries pumping green hydrogen into ammonia and methanol, to island microgrids locking in local, climate-resilient power. Private players are lining up for pilot tests, and NST backing paves a clear runway from the lab bench to real-world demos. As nations race toward hydrogen production goals, KIER’s win offers a credible blueprint for big-time, sustainable energy from the sea.

Company and Sector Context

KIER has been around since 1977, driving South Korea’s energy R&D scene. They’ve designed everything from alkaline and solid oxide fuel cell stacks to cutting-edge water-splitting catalysts, and led demo projects in hydrogen supply, storage and certification. Backed by the Ministry of Science and ICT and propped up by NST funds, KIER sits at the heart of the domestic hydrogen ecosystem. Recent tie-ups with industry and government funding are fast-tracking commercialization. This carbon cloth electrode fits right into KIER’s mission: turn groundbreaking research into market-ready solutions that beef up national energy security and sync with global decarbonization drives.

Looking Ahead

Dr. Han and his team aren’t resting on their laurels. They’re eyeing a stretch past 1,000 hours of nonstop operation, refining the manufacturing process for meter-scale sheets, and slotting prototype cells into full-stack electrolyzer modules. Joint trials with coastal wind farms are penciled in for late 2026, with seawater-based pilot refueling stations due by 2027. Hitting gigawatt-level rollouts will hinge on carbon cloth substrate supplies and acid-treatment lines, but KIER’s already roped in domestic materials firms for co-development. If they pull it off, the levelized cost of hydrogen could dip below $2 per kilogram—going toe-to-toe with gray hydrogen and checking off global targets. Beyond greening power and transport, this tech could pivot to ammonia production using seawater-derived hydrogen, delivering a low-carbon feedstock for fertilizers and industrial chemicals. In a world where every drop of freshwater counts, KIER’s seawater electrolysis leap is a powerful blueprint for the next wave of sustainable energy innovation. For any coastal nation chasing hydrogen scale-ups, seawater electrolysis could become a crown jewel.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.