Hydrogen Production: Electrified Catalytic Methane Decomposition Goes Carbon-Free

August 4, 2025A Slovenian crew from the National Institute of Chemistry, led by Sergey Girshevich, David Bajec, Stanislav Yakushkin, Janvit Teržan and Blaž Likozar, pulled off something pretty remarkable in the realm of hydrogen production. Their groundbreaking paper in the International Journal of Hydrogen Energy introduced a brand-new take on making hydrogen and solid carbon — all without a trace of CO2.

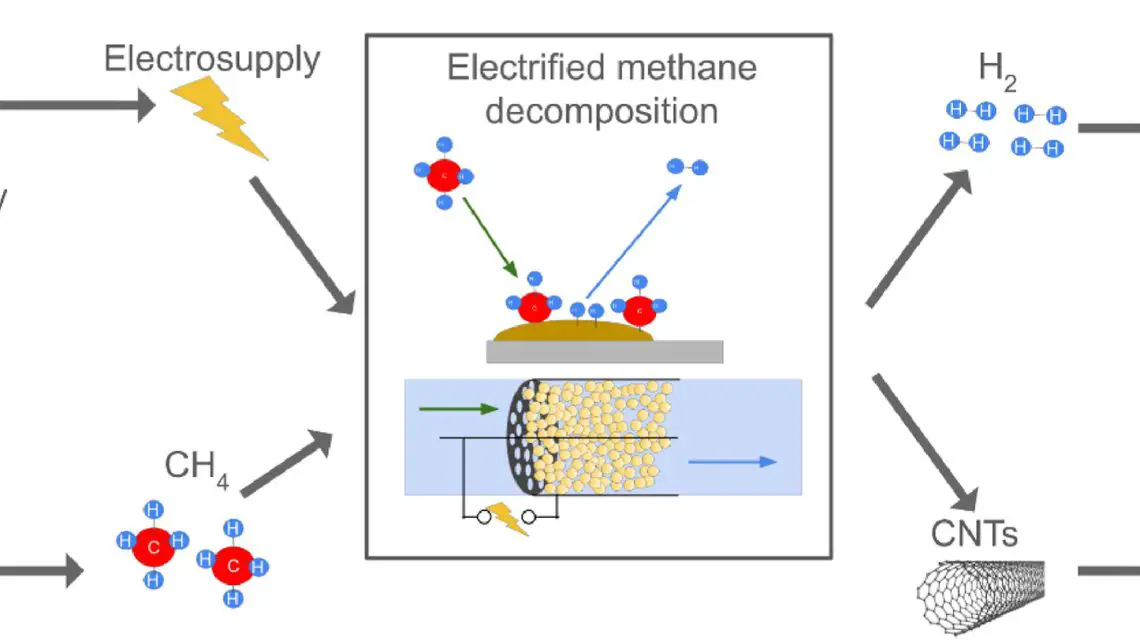

They basically rewired catalytic methane decomposition (CMD) using plasma, microwave and induction heating, proving that with 100% renewable juice, CH4 splits into H2 gas and fancy nanostructured carbon, and you don’t end up spewing greenhouse gases. It’s a neat fix for industrial decarbonization.

Here’s why it matters:

- Zero-emission technology: CMD skips over CO and CO2 production, unlike old-school steam methane reforming.

- Targeted energy: Whether it’s plasma, microwave or induction heating, you’re pouring power right where you need it, cutting down on wasted heat.

- Pure H2 output: The hydrogen is clean enough for fuel cells straight off the bat—no extra separation steps.

- Valuable carbon byproduct: You get nanotubes, nanofibers or graphene, ready to sell into the advanced materials markets.

Publication & Industry Validation

Landing in the pages of the International Journal of Hydrogen Energy—published by Elsevier under Hydrogen Energy Publications LLC—the study got the stamp of approval from one of the field’s most rigorous peer-review processes. Given IJHE’s reputation and citation count, this isn’t just academic fluff; it’s heavy validation that electrified CMD is stepping into the limelight of zero-emission technology.

How Electrified CMD Works

At its heart, CMD cracks methane over a solid catalyst—often metal or carbon-based—and churns out hydrogen gas while depositing carbon. The twist here is how you heat it. Traditional setups blast a furnace to crazy-high temps. Instead, the Slovenian team channels electricity right into the reaction zone:

Plasma creates a soup of high-energy electrons and ions that rip C–H bonds apart like butter.

Microwave heating gets polar molecules buzzing and turbocharges catalyst activation, so you dodge nasty thermal gradients.

Induction heating induces currents directly in conductive catalysts via oscillating magnetic fields, giving you smooth, uniform heat.

Together, these tricks ditch combustion emissions, ramp up energy efficiency and let you tweak conditions on the fly to keep catalysts from choking on carbon buildup.

Historical Context & Evolution

Believe it or not, CMD has roots stretching back to the mid-20th century. Early trials ran into hurdles like catalyst deactivation and sloppy carbon handling. Fast-forward to today: breakthroughs in nanomaterials, smarter reactor designs and versatile electrification have breathed new life into the approach. The Slovenian team’s innovation is really the cherry on top, weaving decades of incremental advances into a unified, pilot-ready method.

Economic & Strategic Implications

Besides slashing emissions, electrified CMD could shake up the balance sheet. The global market for carbon black, nanotubes and graphene is huge—think tens of billions across automotive, electronics and more. By selling that side stream of nanocarbon, you can offset a big chunk of hydrogen production costs, making the business case much sharper. Plus, it dovetails nicely with industrial decarbonization goals and even opens a revenue stream for regions sitting on natural gas that’d otherwise get flared. In places with surplus renewable power—where grids sometimes have to curtail production—CMD offers a way to turn that excess electricity into both clean fuel and high-value materials.

Research & Scale-Up Efforts

Scaling from lab bench to pilot plant is always a tough stretch. The team has nailed impressive hydrogen selectivity so far and is now sketching out reactors that handle multiple cubic meters of methane per hour. Key innovations include catalysts with better metal dispersion on carbon supports—tougher against deactivation—and modular reactors that scrape off carbon continuously so you’re not stopping the show. They’re teaming up with European equipment makers to tinker with microwave-transparent reactor walls and refine induction coil layouts. On the digital side, real-time sensors and smart control algorithms are in the works to keep tabs on temperature, carbon buildup and H2 purity, ensuring safe, efficient runs at scale.

Environmental Impact & Life-Cycle Considerations

From a life-cycle angle, electrified CMD can really cut the greenhouse gas footprint compared to conventional steam methane reforming—assuming you’re running on renewable juice. The solid carbon byproduct locks away carbon that’d otherwise end up in the atmosphere, and it can swoop in as a drop-in substitute for petroleum-derived carbon black. That said, we still need robust life-cycle analyses to nail down trade-offs around catalyst production, electricity sourcing and what happens to nanocarbons at end-of-life. Policies like carbon pricing or subsidies for low-carbon hydrogen and advanced materials could tip the scales even more in CMD’s favor.

Positioning in the Hydrogen Landscape

In the rainbow of hydrogen colors, electrified CMD slots in as turquoise hydrogen—a neat middle ground between grey (unabated SMR), blue (SMR with carbon capture) and green (electrolysis). With global hydrogen demand expected to soar from about 70 million tons in 2019 to over 200 million by 2030, we’ll need a mixed bag of low-carbon pathways. While green hydrogen will undoubtedly drop in price, CMD offers a complementary channel wherever natural gas meets cheap renewable electricity. It’s especially attractive for hard-to-abate sectors like steelmaking, chemicals and heavy transport, which crave high-purity hydrogen and can make good use of nanocarbon off-takes.

Challenges & Next Steps

There’s still a mountain to climb before CMD becomes routine:

- Catalyst lifespan: Keeping the catalyst humming for thousands of hours without swapping it out constantly.

- Continuous carbon removal: Harvesting that solid carbon without hitting the pause button on the reaction.

- Techno-economic validation: Piloting fully integrated systems to crunch the numbers on costs, energy draw and carbon revenue.

- Supply chain alignment: Locking in buyers for nanocarbons at scale and managing gas feedstock logistics.

Knocking down these barriers will take tight collaboration between academics, reactor builders and end users—co-designing pilot facilities and stress-testing cost models under real-world conditions.

Looking Ahead

Electrified CMD sits right at the crossroads of sustainable energy and advanced materials manufacturing. It promises a double win: zero-emission hydrogen for the next wave of fuel cell tech and high-purity nanocarbon for cutting-edge applications. The Slovenian team’s work lays a solid foundation, but true commercial success hinges on boosting catalyst resilience, weaving together reactor and carbon harvest systems, and carving out market pathways for the carbon byproduct. The next few years will be critical as pilot plants ramp up, life-cycle data rolls in and partnerships form to bridge lab breakthroughs with industrial deployment—potentially making electrified CMD a cornerstone of the growing hydrogen infrastructure and driving real progress in industrial decarbonization.

Access to the research paper here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.