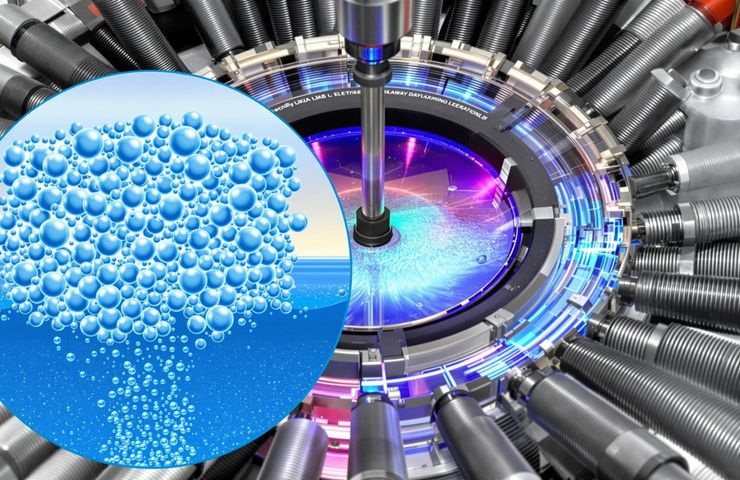

Hydrogen Production: Magnetic Field Restructures Water to Boost Electrolysis Efficiency

August 8, 2025Picture this: you slap a 1 Tesla magnet onto your electrolyzer and suddenly the energy bill for hydrogen production gets a major haircut. No science fiction here—Chinese researchers led by Dong Wang and Zhi Wang proved it. In a paper published on 7 August 2025 in JACS Au (American Chemical Society), they showed that by steering the hydrogen-bond network of interfacial water via a steady magnetic field, they sliced off about 50 millivolts of overpotential for the hydrogen evolution reaction and cranked current density up by 15.4% under industrial alkaline electrolysis conditions.

New Approach to Green Hydrogen

The real pain point in water splitting has always been that energy hump at the cathode where H₂ forms. Folks usually chase fancier catalysts or tweak flow dynamics, but this team went straight for the water itself. They dunked a run-of-the-mill alkaline electrolyzer (using potassium hydroxide) into a uniform 1 Tesla magnetic field while it was humming along. Thanks to the vibrational Stark effect, water molecules near the electrode reshuffle into more asymmetrical DDAA (donor-donor-acceptor-acceptor) clusters. These lopsided water gangs hand off protons and electrons much faster, slicing the energy penalty for H₂ evolution.

Technical Insight

Under the hood, this trick leans on the magnetic field-driven interface hydroxylation mechanism. Fire up that 1 Tesla field and infrared plus Raman spectroscopy light up shifts in interfacial OH bond vibrations—clear proof the VSE is on the job. Molecular dynamics simulations back it up, showing those skewed DDAA water structures hanging around the catalyst boundary and making hydrogen detachment a breeze. In practice, the team logged a steady 50 mV drop in overpotential and a 15.4% jump in current density at realistic loads. Even better, these gains held strong for over 10 hours in a pilot-scale (2 Nm³/h) cell, proving it’s not just a lab parlor trick.

Implications for Industry

Chopping off a few tens of millivolts might sound small, but on an industrial scale it translates to serious energy savings. For green hydrogen producers, that could mean lower operating costs, ramped-up throughput, and a sharper edge in the market. Industries targeting industrial decarbonization—from ammonia makers to steel foundries and heavy transport fleets—stand to benefit big time. And unlike a high-cost catalyst swap, retrofitting magnets onto existing electrolyzer stacks is surprisingly low-key. You can bolt on permanent magnets or drop in electromagnets without gutting your cell chemistry, so plant owners could fast-track field trials and rollouts.

What’s more, since this tweak doesn’t monkey with the catalyst itself, you sidestep the usual durability trade-offs. It complements both current and next-generation electrodes, smoothing the path for faster commercial adoption.

Looking Ahead

So far, the spotlight has been on the alkaline hydrogen evolution reaction, but the team suspects other electrocatalytic chores—like oxygen evolution or CO₂ reduction—might also reap rewards from interfacial water reshuffling. Those ideas still need experimental proof, but they light up new research directions in electrolysis. “We’re only scratching the surface of how magnetic fields can reshape reaction environments at the molecular level,” says co-corresponding author Dong Wang. “This could be a universal dial for tuning kinetics across a range of clean‐energy technologies.”

With the global push for sustainable energy hotter than ever, even small hacks that curb energy losses—like flipping on a magnet—could be game-changers. Having nailed pilot-scale success, the researchers are already lining up extended trials and partnerships with electrolyzer makers. If all goes to plan, switching on a magnetic field might soon be standard practice in tomorrow’s low-carbon hydrogen plants.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

Please to see the use of a magnetic field in the production of hydrogen when using electrolysis. Soon graphene’s unusual magnetic properties will be harnessed to further enhance and improve this amazing breakthrough using magnetic fields in hydrogen production.

Energy for the world, endless energy and climate warming solved.