Hydrogen Revolutionizes Ceramics: Técnicas Reunidas’ H2toGreenCeramics Pilot

November 12, 2025Ever wondered how green hydrogen could turn centuries-old manufacturing on its head? In Spain’s Valencian Community—where ceramic tiles and frits are practically a local obsession—a bold pilot kicked off on 01/11/2025. Called H2toGreenCeramics, it’s all about swapping out carbon-heavy natural gas in kilns for hydrogen produced onsite via cutting-edge electrolysis, a neat example of scalable hydrogen production in action.

A Ceramics Hub Ready for Change

Long before sustainability became a buzzword, the provinces of Castellón and Alicante were already molding local clay into everything from sleek tiles to high-tech frits. But those fiery kilns—cranking above 1,200 °C—have traditionally guzzled natural gas, making the area one of Europe’s top industrial CO₂ emitters. With the EU Green Deal tightening the screws on emissions, local players are eyeing industrial decarbonization as their next frontier.

Collaboration Across the Value Chain

At the wheel is Técnicas Reunidas, the Spanish EPC powerhouse since 1960. They’ve pulled together a dream team: the Instituto de Tecnología Cerámica (ITC) hosts the pilot line at its Low Carbon Plant in Almassora, AIJU brings top-tier materials testing and process integration, and Proying XXI Ingeniería will run real-world trials on modified burners to ensure quality and safety stay rock-solid.

Battling Carbon-Heavy Processes

Picture kilns humming around the clock, burning millions of cubic meters of gas every year. That’s a budget-buster on your energy bill and a planet-buster on your carbon tally. Historically, the Valencian ceramics cluster has worn the “high emissions” label like a badge of honor—but with green hydrogen stepping up, those days could be numbered.

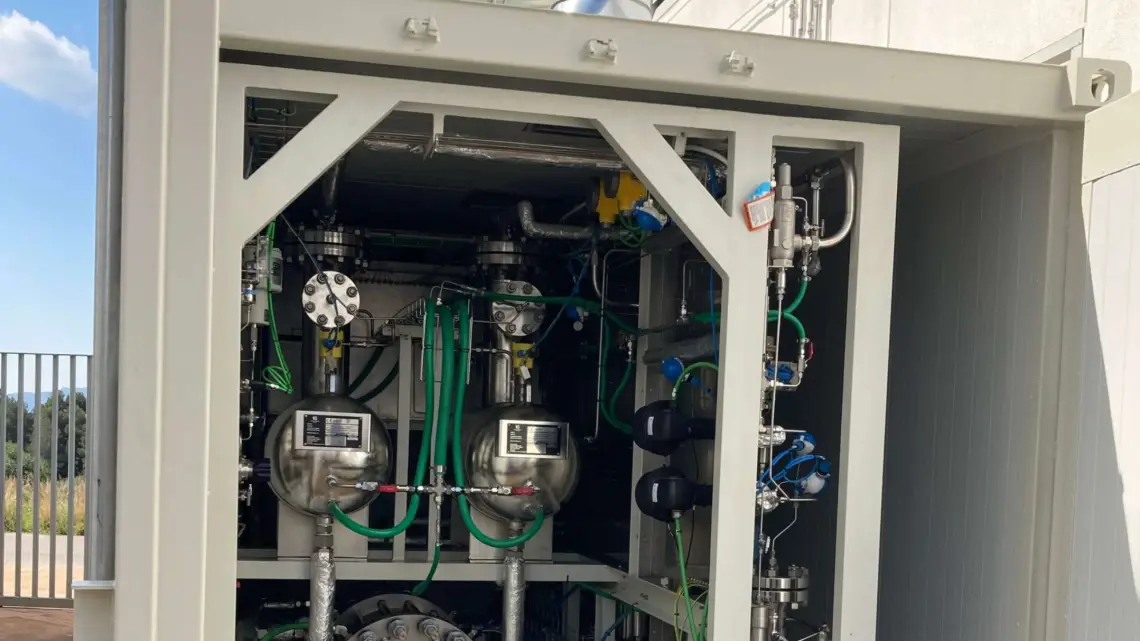

How Alkaline Electrolysers Enable the Shift

Phase one rolls out a 50 kW alkaline electrolyser at the ITC’s Low Carbon Plant. Using a potassium hydroxide solution, it splits water into hydrogen and oxygen through classic electrolysis. The hydrogen gets dried, piped straight to modified burners, and blended up to 20% by volume with natural gas. Engineers then geek out on flame stability, temperature uniformity and efficiency—because consistency is everything when your tile’s finish is on the line.

Business Case: Blending for Decarbonization

No one wants to gut their kilns overnight. Switching straight to 100% hydrogen can over-stress hardware and balloon retrofit costs. A phased blend, on the other hand, spreads technical risk, spaces out investment, and still slashes emissions from day one. Early tests at 20% hydrogen have already shown a 10–15% CO₂ cut—without slowing cycle times or hiking maintenance bills—proof that even the biggest skeptics can’t ignore.

Scaling Up to Industrial Volume

Next up, phase two cranks the scale to a 500 kW electrolyser at a commercial frit plant run by Proying XXI Ingeniería. Set for late 2026, this system aims for round-the-clock hydrogen blending on full-size kiln loops. If it handles the daily grind like the pilot, it’ll prove that world-class manufacturing and sustainable energy can go hand in hand.

Backing the Transition

This whole endeavor stands on a cocktail of support: the regional government of Valencia, national R&D grants, and a hefty slice from Horizon Europe. Spain’s sun-drenched and wind-swept landscape not only fuels renewables but also drives scalable hydrogen production. Building robust hydrogen infrastructure—from onsite electrolysers to distribution pipes—bolsters energy security and hedges against volatile gas prices.

Implications for EU Climate Goals

Ceramics often get tagged as “hard-to-abate,” with few low-carbon detours in sight. But cracking a commercially viable electrolyser-to-burner blueprint could ignite demand for hundreds of megawatts of renewable hydrogen across Europe. Imagine every ceramic hub—and even glass or cement plants—joining in. We’d be looking at millions of tonnes of CO₂ trimmed annually, a serious leap toward the EU’s net-zero vision by 2050.

Challenges Ahead

It’s not all smooth sailing. Hydrogen’s tiny molecules sneak through the tiniest cracks, so leak detection and boosted safety protocols are non-negotiable. Electrolysers also draw big chunks of power, which might mean grid upgrades or dedicated renewables. And tuning burners to keep flames hot—but NOₓ low—feels like walking a technical tightrope. Predictable policies and friendly tariffs will be the cherry on top, making the economics stack up alongside the environmental wins.

Next Steps Beyond the Pilot

When the pilot wraps, the crew will draft operational playbooks, refine burner designs, and explore on-site storage hacks—think pressurized tanks or metal hydrides—to stash hydrogen and decouple electrolyser cycles from kiln runs. They’ll also model dynamic grid interactions, ramping electrolysers whenever wind or sun peaks. All that data will feed into robust CAPEX, OPEX and payback models, so future investors know exactly what they’re signing up for.

Come winter, those first green hydrogen flames in Castellón and Alicante won’t just make for a great photo op—they’ll mark a turning point in sustainable energy for heavy industry. If H2toGreenCeramics hits its targets, Spain’s ceramic titans will not only shrink their carbon footprints but also set the gold standard for large-scale decarbonization with zero-emission technology.

About Técnicas Reunidas

Técnicas Reunidas is a Spanish engineering, procurement and construction (EPC) leader founded in 1960. Renowned for major energy and petrochemical projects, the firm has branched into green hydrogen and renewable initiatives, championing industrial decarbonization worldwide.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.