Hydrogen Storage Materials: Scandium-Enhanced Aluminum Alloy Resists Embrittlement

December 4, 2025Ever wondered why some lightweight, bulletproof materials crack under pressure? Chasing a hydrogen economy, engineers pinned their hopes on aluminum alloys for storage tanks and pipelines—crucial pieces of modern hydrogen infrastructure. But hydrogen embrittlement turned out to be a real party crasher: microscopic H atoms sneak into grain boundaries and turn once-tough metals into ticking time bombs.

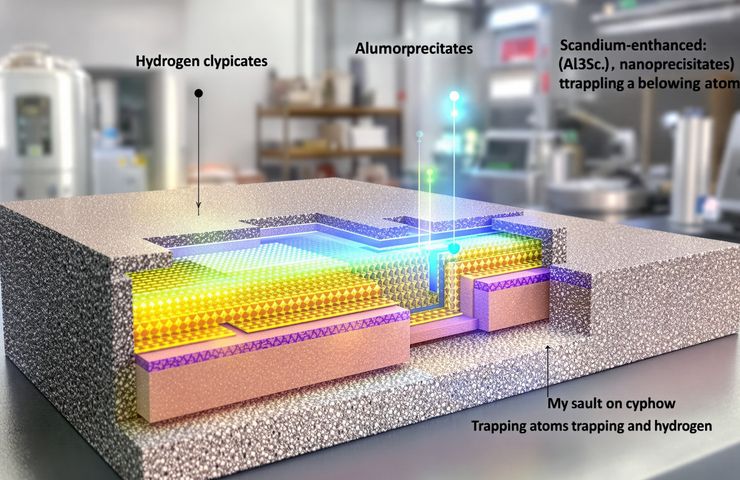

Enter the team at the Max Planck Institute for Sustainable Materials (MPI-SusMat) in Germany, joined by innovators in China and Japan. They’ve cooked up a scandium-enhanced aluminum-magnesium alloy that boosts tensile strength by 40% and slashes hydrogen-driven cracking by five times—all without losing that lovely ductility. It’s like getting a sports car’s performance while still squeezing in your kids and groceries—and it’s a big leap forward for green hydrogen efforts.

Before this breakthrough, materials tough enough to shrug off hydrogen were too soft to hold high pressure, while the strong ones would fracture like glass under a heavy hydrogen load. This new alloy rides on years of work in computational modeling and phase engineering, where theory and hands-on experiments teamed up to map out every hiding spot for hydrogen atoms.

Anatomy of a Material Engineering Feat

This isn’t magic—it’s meticulous science. Using atom probe tomography, researchers peered down to the atomic scale and saw exactly how hydrogen atoms flock to the nanoprecipitate shell instead of invading grain boundaries. The result? A material that delivers uniform tensile elongation even under hefty hydrogen pressure, smashing previous performance records for aluminum alloys. Picture a metal that refuses to snap no matter how much hydrogen you throw at it.

Mining Scandium and Supply Chain Notes

Yes, scandium has a reputation for being rare and pricey, which could sound like a dealbreaker for industrial decarbonization. But the magic here lies in tiny amounts—just enough to seed those powerful nanoprecipitates. Early tests suggest we can tap into secondary sources, even salvaged scandium from red mud, to keep costs in check. Smart recycling loops and partnerships with existing rare-earth players could turn this lab marvel into a real-world champion.

From Foundry to Factory Floor

Scaling up wasn’t a puzzle either. The team used water-cooled copper mould casting, a method already popular in heavy industry, then dialed in thermomechanical processing—hot rolling, cold stretching, and multiple anneals—to refine the grains and spread those nanoprecipitates evenly. The best part? Steel and aluminum mills can slot this alloy into their lines with minimal tweaks, making it the kind of “drop-in” upgrade that production managers dream about.

Shoring Up Hydrogen Infrastructure

Imagine storage tanks, transport vessels, and pipelines built with walls 10–20% thinner, yet just as safe. That’s a game-changer for hydrogen storage hubs or high-pressure cylinders: more capacity per dollar, less material hauled around, and fewer safety checks crowding your calendar. It’s a direct boost to building reliable hydrogen infrastructure and hitting those sustainable energy targets with confidence.

The Automotive Angle

Automakers, take note. Every gram of weight you shave off a hydrogen fuel cell vehicle tank means more miles per drive. Slip in an alloy that literally laughs at hydrogen’s worst tricks, and you’re looking at buses and trucks that weigh hundreds of kilos less, have a lower center of gravity, and maybe even surpass their current range. That’s not sci-fi—it’s exactly what this material can deliver on the road.

Economic and Environmental Ripple Effects

Stronger, lighter, and safer materials drive down the total cost of ownership for hydrogen systems, which could turbocharge green hydrogen projects worldwide. Investors and governments love a tech that cuts costs across the board—fewer materials to mine, leaner shipping, and less energy spent on manufacturing. Plus, tight scandium recycling loops mean we’re closing the loop on rare-earth waste, ticking off circular economy goals while bolstering supply stability.

Beyond Hydrogen: A Platform for Other Alloys

What’s extra exciting is that this dual nanoprecipitate approach isn’t just for aluminum-magnesium-scandium. The same playbook—controlled phase engineering to trap pesky atoms—could transform high-strength steels for offshore rigs or beef up titanium parts in aerospace. It’s a blueprint for how smart materials design can smash old performance limits and push us closer to full-scale industrial decarbonization.

Charting the Road Ahead

With a paper in Nature (2025;641(8062):358-364. doi:10.1038/s41586-025-08879-2), this research has major street cred. The next steps? Lock down regulatory certifications, update welding codes, and tweak safety standards for an alloy this fresh. Fortunately, existing foundries already have compatible moulds and thermomechanical gear, so pilot runs are slated for late 2025. And with Europe aiming for 100 GW of electrolyzers by 2030, materials like this will be the unsung heroes of the green hydrogen revolution.

So next time you spot a gleaming hydrogen tank or a robust pipeline, remember the nano-level showdown happening inside—tiny precipitates wrestling with hydrogen atoms to keep everything running smoothly. It’s one more vital piece in the puzzle of building a truly sustainable energy future. If materials keep evolving like this, that future might be closer than we think.

source: nature.com

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.