IMDEA’s Strained Catalysts Challenge Platinum

January 22, 2026Here’s something you might’ve missed: platinum isn’t the only game in town for affordable green hydrogen. At Madrid’s IMDEA Materials Institute, Dr. Harun Tüysüz and his crew put intermetallic thin films under about 1% mechanical strain—and blew past all expectations. Suddenly, budget-friendly alloys like Ag₃In, Ni₃Fe and Ni₃Sn hit a staggering 71% of platinum’s performance in the hydrogen evolution reaction (HER), all at a fraction of the cost. That’s a seismic shift for large-scale electrolysis and hydrogen production budgets. If you’re looking at the horizon of sustainable energy, this is one to bookmark.

No smoke and mirrors here. This breakthrough just scored in ACS Catalysis, and it got a big thumbs-up from Spain’s Ministry of Science, Innovation and Universities through the ATRAE programme. It slots right into IMDEA’s wider green hydrogen push—think CHOSEN-CAT and the Madrid-backed GreenH2-CM initiative. The Catalysis and Energy Materials group, spun out in 2023 with 84 active R&D projects, is in it for the long haul across photo- and electrocatalysis. And this isn’t just about early-stage discovery—it’s about lining up everything from fundamental lab work to pilot-scale demos under one roof.

A Simple Tweak with Huge Payoff

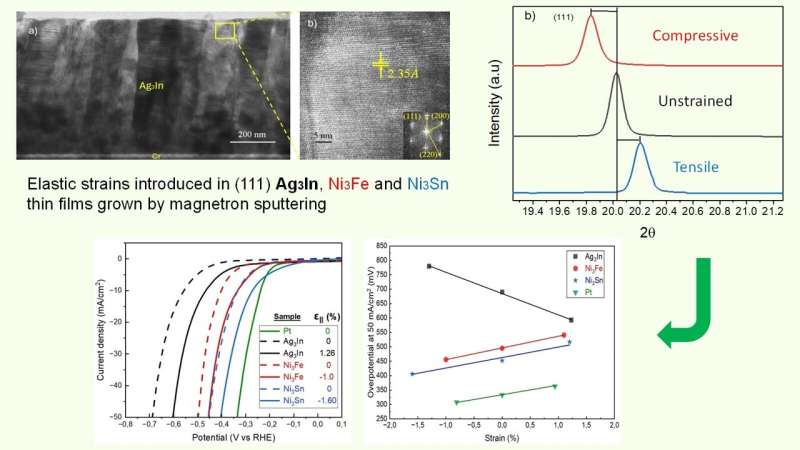

We all know platinum catalysts nail low overpotentials and strong currents, but they cost an arm and a leg—and come with all sorts of geopolitical headaches. So, the IMDEA squad—Jorge Redondo, Dr. Jayachandran Subbian, Dr. Miguel Monclús, Dr. Valentín Vassilev Galindo, Prof. Jon Molina and Prof. Javier LLorca—decided to flip the script. By stretching Ni₃Sn by just 1.26% at the atomic level, its HER activity jumped to 71% of platinum’s benchmark. They tweaked Ag₃In with tensile strain and sharpened Ni₃Fe under compression. The result? Catalyst costs that suddenly look a lot less terrifying.

Why It Matters for Hydrogen Production

If you’re running a PEM or alkaline electrolyzer, catalyst costs aren’t a footnote—they’re front and center. Right now, platinum can swallow up 20–30% of your stack’s budget. Swap it for strained intermetallics and those numbers plummet, pushing green hydrogen production closer to cost parity with fossil-derived hydrogen. We’re not talking about pocket change; even trimming a few cents per kilogram of H₂ can translate into multi-million-dollar savings over a facility’s lifetime. Europe’s Green Deal models already show that every gram of platinum replaced knocks your levelized cost of hydrogen (LCOH) down by cents, which quickly scale to dollars per kilogram.

The Nuts and Bolts of Elastic Strain Engineering

“Elastic strain engineering” might sound like materials-science lingo, but it’s surprisingly straightforward. You stretch or compress thin intermetallic films by around 1%—enough to tweak their internal lattice without shattering it. That nudge shifts the d-band center, dialing in the Goldilocks zone for hydrogen binding: not too tight, not too loose. IMDEA’s team laid these films on flexible substrates, applied the strain mechanically, and tested them in typical alkaline electrolytes. They saw current densities and Tafel slopes that rival Pt/C benchmarks, all while maintaining stability.

Big Picture: Strategic Implications

Europe’s betting big on sustainable energy and industrial decarbonization, and it needs technologies that can scale affordably. With initiatives like Brussels’ Hydrogen Strategy and Spain’s GreenH2-CM laying the groundwork, reliable, low-cost catalysts are the missing piece. Silver, nickel, iron and tin are far more abundant than platinum, slashing geopolitical risk and supply-chain headaches. State support—like the ATRAE funding for CHOSEN-CAT—is already flowing in that direction, signaling where the money’s headed next.

Europe’s blueprint for a hydrogen economy—from onshore pipelines to underground salt-cavern storage—is only as strong as its weakest link, and today that link is catalyst affordability. If countries want to fill those pipelines and juice up compressors for green hydrogen, they need materials that won’t blow budgets or buckle under pressure. That’s exactly where strained intermetallics step in, offering performance that gets you within shouting distance of platinum without the wild price tags.

Yet, let’s not get carried away. Lab wins can stumble during scale-up: contamination creeps in, films crack under mechanical fatigue, and real-world impurities can trigger degradation pathways we hadn’t even considered. Will these strained films hold steady after thousands of hours under industrial cycling? That’s the million-euro question before anyone can safely bank on this being a done deal.

The Road Ahead

IMDEA isn’t putting all its eggs in one basket. Alongside these electrocatalysis breakthroughs, Dr. Tüysüz is eyeing halide perovskite photocatalysts under CHOSEN-CAT—imagine solar-driven hydrogen production hand-in-hand with polymer recycling. It’s a smart hedge: if elastic strain hits a snag, perovskites could pick up the slack and keep the momentum going in sustainable energy innovations.

Now it’s up to engineering teams to step in. We need pilot plants cranking out megawatts with strained intermetallics, rigorous longevity tests that mirror real-world conditions, and cost curves that prove out in genuine project bids. If this all lines up, elastic strain engineering could rewrite the playbook on cheap, reliable green hydrogen—and mark a massive leap forward in industrial decarbonization. Keep your eyes on Madrid; IMDEA’s breakthrough might just become the global gold standard.

source: pubs.acs.org

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.