KAIST Crafts Rapid Microwave Sintering for Ceramic Electrochemical Cells

December 8, 2025What if you could shrink an hours-long, 1,400 °C sintering marathon down to a 10-minute, 1,200 °C sprint? That’s exactly what KAIST engineers led by Professor Kang Taek Lee just pulled off. Their rapid microwave sintering technique for ceramic electrochemical cells—the beating heart behind hydrogen production and next-level energy storage—blasts through traditional heat-and-hold routines, chopping both temperature and time. The result? A leaner, greener way to make both Solid Oxide Electrolysis Cells (SOECs) and Protonic Ceramic Electrochemical Cells (PCECs), setting the stage for cost-effective, robust hydrogen systems.

- Production time slashed from hours to minutes

- Peak temperatures dropped by more than 200 °C

- Energy consumption slashed

- Thermal stress all but erased

- Sharper, more reliable microstructures

- Digital twins baked in for smarter design

Ceramic sintering has long been the thumb in the door for scaling high-temp electrolysis—that tricky process to crank out clean, green hydrogen. With conventional furnaces, you crank up to about 1,400 °C and wait for hours to get the density and conductivity you need. That not only racks up energy bills (we’re talking over 1 kWh per kilo of ceramic) but also restricts what materials you can use for interconnects and seals. Plus, temperature swings leave microcracks that undermine stack life, forcing you into pricey alloys and fancy thermal tricks. Meanwhile, the promise of PCECs at 300–600 °C kept us dreaming of lower temps, but sintering was the anchor holding costs—and innovation—back.

A New Chapter in Manufacturing

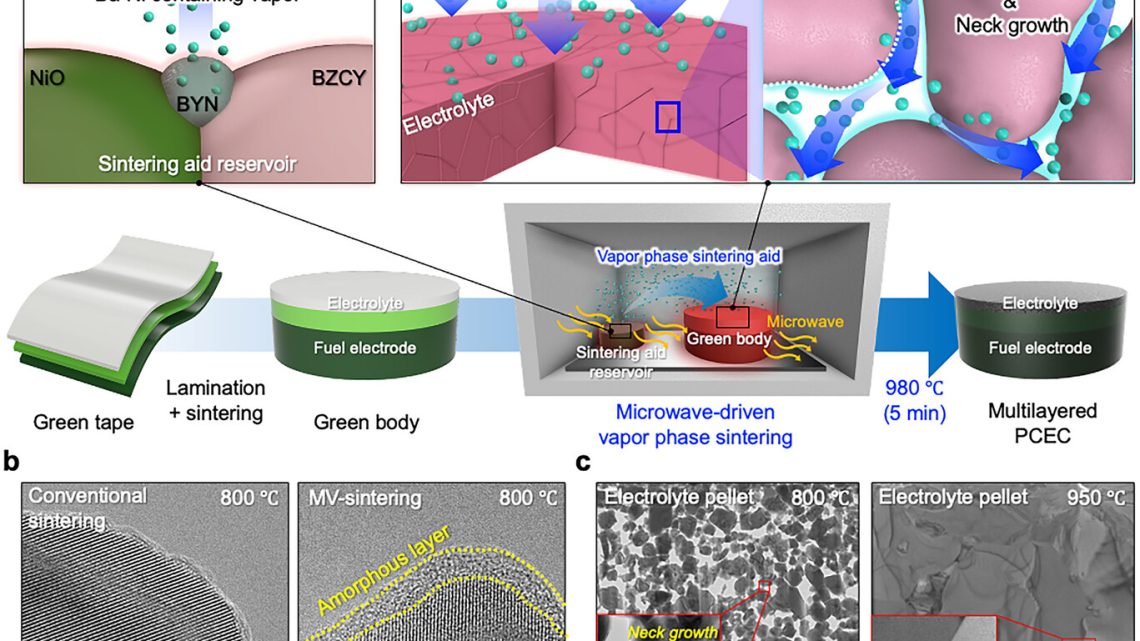

Instead of that old heat-from-the-outside approach, KAIST flips the script with volumetric microwave sintering. They fire microwaves right into the ceramic powder, so the whole thing heats up from the inside out and densifies evenly. The kicker? They hit comparable—or even better—microstructures at just 1,150–1,200 °C in 10–15 minutes, versus the usual 2–4 hours at 1,400 °C. Best part: cooler peaks mean you can swap in cheaper goodies like stainless steel interconnects and polymer seals without frying them.

How Microwave Sintering Works

Stay with me—here’s the science bit made simple. Microwaves at 2.45 GHz get absorbed by polar bonds and conductive grains in the ceramic, converting straight into heat all through the volume. That kills thermal gradients and turbocharges the mass transport that welds grains together. KAIST’s setup even has real-time feedback controlling power density and ramp rates, so there are no hot spots or annoying arcing. In practice, a green tape—loaded up with electrodes and electrolytes—goes in, and a sintered, dense cell pops out a few minutes later, ready to head into stack assembly. Total game-changer for production footprints and cycle times.

Digital Twins Optimize Performance

Beyond the oven, the team leaned on digital twins—virtual stand-ins that mimic gas diffusion, reaction kinetics, and heat flows inside the cell. By running simulations of steam channels, electric currents, and temperature swings, they tweaked channel layouts, porosity maps, and layer thicknesses long before firing up the furnace. This virtual-first strategy slashes trial-and-error loops from months to days, and flags potential failure points whether you’re in the 300–600 °C protonic realm or the classic solid oxide range.

Strategic Impacts for the Hydrogen Economy

In the race to decarbonize, affordable, dependable electrolyzers are the linchpin for a thriving hydrogen production industry. KAIST’s breakthrough delivers on several fronts:

- Cost savings: Up to 30% less energy baked into manufacturing

- Speed: High-volume output in record time

- Material flexibility: More choices for interconnects and seals

- Durability: Fewer cracks, longer stack life

- Modularity: Tailored setups for on-site, compact hydrogen generation

That means a leaner levelized cost of hydrogen (LCOH) and a greener bottom line—making green hydrogen a tougher competitor in industrial, transport, and grid-balancing applications.

Wider Context and Next Steps

Governments and big players worldwide are pouring cash into green hydrogen hubs to decarbonize steel, chemicals, heavy transport—you name it. The EU’s Green Deal and the US Inflation Reduction Act are fronting R&D billions for electrolyzers. Yet, stack costs still loom large. By slashing both capex and opex, microwave sintering could tip green hydrogen over the cost hump versus fossils by mid-decade.

Where to from here? It’s all about scaling up—taking lab-scale chambers to pilot lines. That means teaming up with kiln makers, materials suppliers, and end users to nail down yield and repeatability. Throw in policy nudges—innovation grants, tax credits for low-carbon hydrogen—and you’ve got a runway for rapid adoption.

Of course, new tech stirs up supply-chain and standards puzzles: Can you source magnetrons and cavity parts in bulk? Will standards bodies rewrite sintering protocols to include volumetric microwave methods? How fast will QA labs certify these parts for high-temp, high-pressure duty? The answers will map out the commercialization journey.

At its core, KAIST’s work marries cutting-edge manufacturing with virtual modeling to bust through the biggest block on the path to scalable electrolysis and fuel cell technology. If pilot runs echo lab success, we could see a new breed of electrolyzer lines cranking out cost-effective, long-lived cells—fueling a more sustainable energy future.

For project leads and tech partners, now’s the moment to jump in. Early sit-downs with research teams, equipment suppliers, and policy folks can unlock funding perks, first-mover status, and a clear roadmap to scale. Microwave sintering might just be the lever that propels green hydrogen—cutting time, chopping costs, and boosting reliability—the three pillars for a zero-emission energy story.

source: wiley.com

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.