KIST Unveils Low-Alkalinity Membrane to Enhance Hydrogen Production

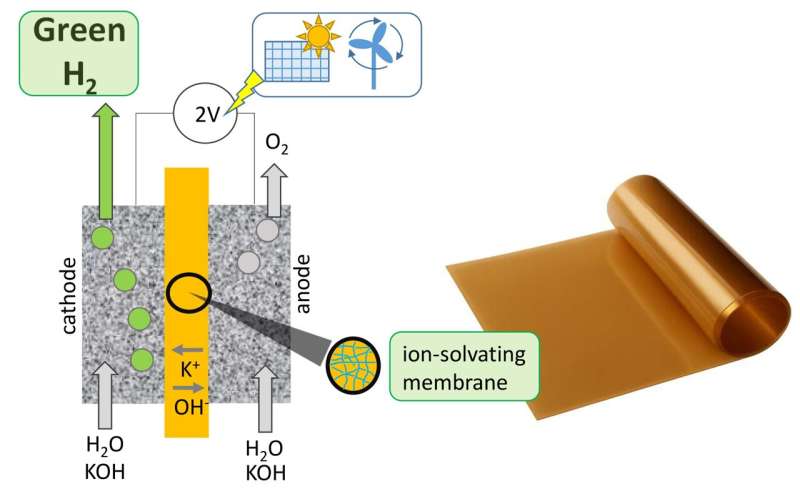

February 4, 2026When it comes to hydrogen production, every fraction of a volt saved and every hour of steady operation can swing the economics in favor of green hydrogen. At the Korea Institute of Science and Technology (KIST), Dr. Dirk Henkensmeier and his team have been hard at work on a slick new sulfonated polybenzimidazole membrane for low-alkalinity ion-solvating membrane water electrolysis (LA-ISMWE). They’re shooting for a membrane that’s super conductive and built to last, even when you dial the electrolyte down to just 1 M KOH. The payoff? Lower power bills and fewer service calls for electrolysis setups.

Core Findings

Here’s the scoop: by adding sulfonic acid groups and crosslinking the polybenzimidazole backbone, the membrane soaks up more KOH without falling apart. In lab tests, it delivered over 100 mS/cm of ionic conductivity in just 1 M KOH—compared to the 20–30 mS/cm you’d get from run-of-the-mill PBI membranes under the same conditions. Toss it into a full-cell at 1.8 V, and you’ll see current densities of 1.7–1.8 A/cm², all while keeping hydrogen–oxygen crossover dangerously low. Even after more than 500 hours at higher temps, the polymer backbone stayed rock solid.

Technical Advances

What’s the magic trick? Those sulfonic acid tweaks crank up the membrane’s polarity, pulling in just enough KOH to form smooth ion highways. A carefully controlled crosslinking step stops it from puffing up too much, which keeps gas separation sharp and mechanical strength intact. Because the structure is thick and dense, you can ditch extra ionomer binders—simplifying the stack design. Best of all, running in a low-alkaline setting means you can swap out pricey platinum-group catalysts for more wallet-friendly alternatives on both electrodes.

Historical Context

Old-school alkaline water electrolysis usually runs on a brutal 5–7 M KOH solution and porous diaphragms to keep gases apart. Trouble is, that high alkalinity eats away at polymers faster than you can say “maintenance.” Early ion-solvating membranes needed north of 20 wt% KOH to even hit decent conductivity, and PBI variants would throw in the towel after a few weeks at 80 °C. Sure, there’ve been tweaks with sulfonated or heat-cured PBI, but this new approach appears to break past that 500–1,000 hour threshold with barely any voltage climb.

Strategic Implications

Dialing KOH back from about 7 M to 1 M isn’t just a numbers game—it translates straight into lower cell voltages and gentler operating conditions. That means you burn less juice per kilo of hydrogen and you’re not wrenching on the system every other month. KIST researchers argue this could be a real game-changer for rolling out electrolysis plants, making green hydrogen more competitive and trimming the total cost of ownership. They even see a chance for South Korea to ramp up local membrane production—right now, most of that market belongs to North America and Europe.

Parallel Developments

All around the globe, labs are juggling different ion-exchange and ion-solvating membranes for both proton-exchange and alkaline setups. Proton-exchange membranes score points for compactness, but they lean on pricey perfluorosulfonic acids. The LA-ISMWE approach feels like a sweet spot: steady, low-alkaline operation using cheaper polymer backbones and non-PGM catalysts. It’s playing in the same sandbox as anion-exchange membrane electrolysis but promises a simpler stack architecture to boot.

The next steps for Dr. Henkensmeier’s crew? Scale up membrane production, slot the material into bigger electrolysis stacks, and push durability tests past that 1,000 hour mark. They’re also keen on real-world pilot runs and testing compatibility with a variety of catalyst mixes. If it all pans out, this membrane could be the unsung hero behind industrial-scale hydrogen production, helping operators slash electricity costs and downtime.

By tackling the trade-offs between performance, stability, and cost head-on, this low-alkalinity membrane nudges us closer to more affordable, large-scale green hydrogen. It’s a solid reminder that innovation in materials remains at the heart of the sustainable energy and fuel cell technology revolution.

source: nature.com

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.