MXene Electrocatalyst Breakthrough Powers Noble-Metal-Free DMFCs

August 7, 2025There’s some exciting news circulating in the fuel cell community: a research team has rolled out a MXene electrocatalyst that might just change the game for direct methanol fuel cells. Using a clever two-step hydrothermal-nitridation process, they’ve crafted a noble-metal-free catalyst that not only rivals traditional platinum-based systems but also shrugs off CO poisoning with ease.

Innovation at the Nanoscale

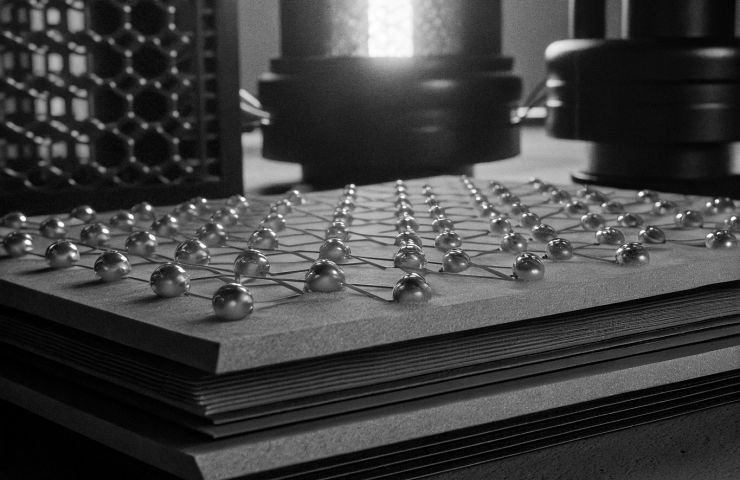

In their latest ACS Applied Energy Materials paper, the researchers describe building a ternary nanocomposite out of Ti3C2Tx MXene, titanium nitride (TiN), and vanadium pentoxide (V2O5). Think of it like a miniature scaffolding: the 2D MXene sheets act as a super-conductive backbone, TiN nanoparticles sprout off that base during a hydrothermal step, and then V2O5 gets evenly sprinkled in during the nitridation phase. The result is a porous, highly accessible network that maximizes active sites for methanol oxidation and electron flow.

A Simple, Scalable Hydrothermal-Nitridation Recipe

This isn’t some exotic, lab-only trick. You start by tossing MXene precursors along with titanium and vanadium salts into an autoclave with plain water. Heat under moderate pressure to forge the oxide intermediate, then introduce ammonia or nitrogen gas at controlled temperature to kick part of the material into a TiN phase while locking in V2O5. The beauty is that it preserves the MXene’s 2D structure, distributes nanoparticles evenly, and avoids the high-vacuum or ultra-high-temperature traps of other methods. Better yet, it’s adaptable to larger reactors—making that jump to real-world production feel much more doable.

Synergy at Work

What really sets this DMFC catalyst apart is how its ingredients play off each other. The MXene backbone delivers lightning-quick conductivity, TiN brings chemical toughness and stability, and V2O5 pulls its weight with strong redox activity. Put them together, and you get a mass activity clocking in at 1246.3 mA mg⁻¹ and a peak power density of 87 mW cm⁻² in alkaline solution—numbers that stack up impressively even against some platinum contenders. Plus, the composite keeps cruising under CO-like intermediates, so performance stays steady in real operating conditions.

Built for the Future: Ditching Platinum

Let’s face it: platinum has been a thorn in the side of DMFCs, driving up costs and demanding constant purification to dodge CO poisoning. By ditching precious metals, this approach slashes material expenses, sidesteps supply-chain headaches, and boosts long-term durability. In plain English, that means leaner, meaner fuel cells for everything from portable electronics to backup power systems.

A Peek into the Past

Direct methanol fuel cells popped up in the 1960s but stalled when platinum-based catalysts priced them out of the market. Fast-forward to the 2000s, and alloyed platinum supports made some headway—but costs stayed sky-high. Enter MXene electrocatalysts in 2011, opening a whole new chapter in 2D materials. This jump to a ternary MXene/TiN/V2O5 blend feels like the real turning point, fusing conductivity, stability, and redox punch all in one.

Real-World Impact & Everyday Perks

Scaling up this hydrothermal-nitridation route could be a game-changer. The starting materials are affordable and easy to handle, and the water-based process keeps things green. No more expensive platinum mining, no wild price swings—just consistent, cost-effective production. On top of that, a CO-tolerant anode means longer runtimes and less downtime for maintenance. These wins are exactly what emerging markets and off-grid setups crave.

A Win for the Planet

Switching to a noble-metal-free catalyst isn’t just good for your wallet—it’s a win for environmental sustainability. Platinum mining can be energy-intensive and ecologically fraught. By leaning on abundant elements like titanium, carbon, and vanadium, this ternary composite shrinks the carbon footprint of catalyst production. And since it all happens in water at modest temperatures, the process sidesteps harsh chemicals and hefty energy bills.

From Lab Curiosity to Commercial Reality

While the lab results look stellar, the best part is how well this aligns with industrial needs. Abundant feedstocks, water-based synthesis, and proven manufacturing lines for TiN and V2O5 mean companies could repurpose existing plants to crank out these catalysts. Lower capex, streamlined supply chains, and no exotic equipment—now that’s a recipe for rapid scale-up.

Hurdles on the Road

Of course, there are a few checkpoints ahead. We’ll need long-term stability tests—thousands of hours under real methanol feeds—to be certain the material holds up. And scaling from a 100 mL autoclave to an industrial reactor without losing performance or creating new environmental issues will take some finesse. Still, given the inherent robustness of TiN and the versatility of the MXene platform, these challenges feel more like stepping stones than roadblocks.

Looking Ahead: Applications Galore

Picture methanol-powered drones that refuel in minutes, remote sensors humming along for months, or emergency backup units that fire up instantly after a blackout. In places where charging stations are few and far between, methanol’s liquid form and high energy density give DMFCs a serious edge. Thanks to this CO-tolerant, platinum-free anode, we’re one step closer to fuel cells that you can trust to run hard and run long without constant upkeep.

The Big Picture

By proving you don’t need expensive platinum to nail top-tier methanol oxidation, this work highlights a broader shift in energy materials: toward abundant, cost-effective, and scalable catalysts. It’s a prime example of how clever materials science can propel entire industries forward, turning lab breakthroughs into practical, built-for-the-future solutions. Bottom line: this MXene electrocatalyst leap isn’t just exciting—it’s exactly the kind of progress the DMFC world has been waiting for.

Access the research paper here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.