Nb-Doped Amorphous Carbon Coating Revolutionizes PEMFC Bipolar Plates

August 27, 2025Setting the Stage in Shanghai’s Science District

It’s a muggy August afternoon when you stroll into Shanghai’s Yangpu Science Park. Skyscrapers, green-glass labs, and whirring test benches fill the horizon—and tucked in among them is a research hub where W. Jin et al. are busy shaking up the global hydrogen game. China’s aiming for carbon neutrality by 2060, and green hydrogen is the star player in slashing emissions from heavy industry, long-haul transport, and power generation. Here, government grants, venture capital, and cross-disciplinary collaborations collide, creating a high-octane environment where breakthroughs happen at warp speed.

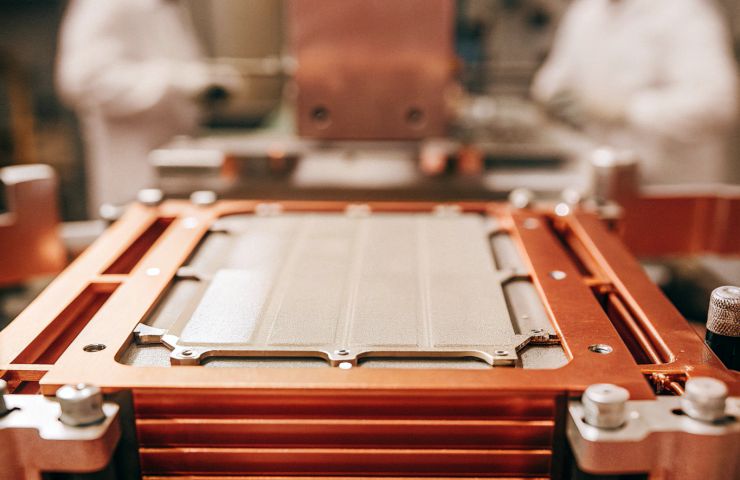

But amidst all the buzz, one nagging bottleneck emerged: the PEMFC bipolar plates. These plates shuttle electrons, coolant, and gas through the fuel cell stack—and if they corrode or develop high contact resistance, the whole operation chokes on inefficiency. For years, engineers leaned on graphite plates: cheap, easy to machine, and corrosion-resistant—until real-world stacks ramped up in temperature and power density, exposing graphite’s bulk and brittleness. The move to stainless steel solved strength and footprint issues, but in the acidic, humid heart of a fuel cell, steel forms oxides that hike electrical resistance and throttle performance.

Over the past decade, coatings like titanium nitride (TiN), chromium nitride (CrN), and various carbides have been trialed to bridge the gap. Most are applied via physical vapor deposition (PVD) or chemical vapor deposition (CVD), techniques that promise purity but struggle with adhesion, cost, and scale. That’s when the electrochemistry crowd turned to a greener, more adaptable approach: deep eutectic solvent electrodeposition. This wet-chemistry method hinted at strong bonds, tunable composition, and the ability to coat complex plate geometries at scale—until the team introduced Nb-ACC (niobium-doped amorphous carbon coating) and stole the show in hydrogen energy technology.

Breaking Down the Nb-ACC Electrodeposition Process

At the heart of this innovation is a tailor-made deep eutectic solvent blend of choline chloride and lactate, spiked with a niobium precursor and ‘sweetened’ by citric acid. Think of these solvents as the Swiss Army knife of electrochemistry: low volatility, adjustable viscosity, and excellent metal-ion transport. When the current kicks in, Nb5+ ions pair up with citric acid, while citric acid itself adsorbs onto the steel surface, priming it for a rock-solid film.

Once voltage is applied, niobium atoms and carbon fragments nucleate together, forming a uniform Nb-doped amorphous carbon coating. Far from being a generic carbon film, this layer delivers a balanced sp2/sp3 network—boosting both conductivity and corrosion resistance. What’s more, it achieves submicron thickness even deep inside the serpentine flow-field channels of bipolar plates. Picture varnish soaking into wood—that’s how this coating adheres, surviving rapid thermal cycling, hydration–dehydration stress, and the acidic, humid battleground of a working fuel cell.

And here’s the kicker: the entire deep eutectic solvent electrodeposition runs at room temperature, sips on power, and sidesteps toxic organics—so it’s kinder to your budget and the planet. Compared to energy-hungry CVD routes, it’s like swapping a gas-guzzler for an electric hybrid. Tuning the niobium-to-carbon ratio? A breeze—just tweak the voltage or solution makeup, paving the way for industrial-scale production of high-performance PEMFC bipolar plates.

Quantified Breakthroughs and Performance

When you dive into the lab data, the results read like a highlight reel: Nb-ACC coatings achieved a sizzling-low contact resistance of just 13.8 mΩ·cm², slashing ohmic losses in high-current-density stacks. Because the film sits perfectly uniform—even in the submicron-thick layer lining the serpentine flow fields—there are no sneaky weak spots where corrosion can sneak in. To stress-test it, the team ran acid-immersion and potentiostatic polarization experiments under low pH, high humidity, and elevated temperature conditions that mirror a real PEMFC in full throttle. The result? Over 300 hours of continuous operation with virtually no drop-off, easily clearing the U.S. Department of Energy’s advanced corrosion-resistance bar.

Mechanically, the Nb-ACC layer held its ground too. In nano-scratch and peel tests, the coating shrugged off forces well above what it would face during stack assembly or thermal cycling. Electrochemical impedance spectroscopy then confirmed the icing on the cake: charge-transfer resistance stayed rock-steady over thousands of open-circuit voltage-hold cycles—a testament to unmatched fuel cell durability. As a reality check, undoped amorphous carbon films underwent the same gauntlet and came up short: higher resistance, earlier pitting corrosion, and weaker adhesion overall. That underscores how niobium is the secret sauce stabilizing the carbon matrix and shielding the stainless steel beneath.

Tying it all together, these advances aren’t just lab bragging rights. They translate to longer service lifetimes, fewer unscheduled maintenance stops, and a leaner total cost of ownership for fleet operators and power plant managers—fuel cell technology poised for real-world impact.

Driving the Hydrogen Economy Forward

Looking at the bigger picture, scalable wins like Nb-ACC could kick hydrogen into high gear. China alone is targeting over 10 GW of PEMFC capacity by 2030—heavy-duty trucks, backup power systems, and distributed generation hubs humming away. By beefing up bipolar plates with Nb-ACC and trimming stack costs by 15–20%, we can accelerate fleet adoption, boost investor confidence, and finally put reliability worries to rest.

And the benefits don’t stop at fuel cells. Those same stainless steel plates serve as electrodes in proton exchange membrane water electrolyzers (PEMWEs). Give them the Nb-ACC treatment, and you crank up efficiency in green hydrogen production. Electrolyzer manufacturers could adopt this low-capex, high-throughput approach, delivering consistent coatings that endure continuous electrolysis cycling—another leap forward for hydrogen energy technology.

Of course, lab-scale triumphs are one thing; commercial-scale rollout is another. The published study flags that while the deep eutectic solvent electrodeposition route looks cost-effective and scalable on paper, we still need independent pilot tests, detailed cost analyses, and real-world production runs. With policymakers, researchers, and industry all singing from the same hymn sheet, the momentum could carry us to an inflection point well before 2030, making Nb-ACC the gold standard for next-gen bipolar plates.

A Glimpse into the Future of Clean Energy

Every now and then, a development gives you a peek at tomorrow. Picture silent, zero-emission hydrogen buses cruising city streets, telecom towers humming on backup fuel cells, and remote microgrids running with minimal downtime. None of that works if the core components—PEMFC bipolar plates—can’t stand the grind. Thanks to the Nb-doped amorphous carbon coating, we’re finally tackling one of the toughest reliability challenges, bringing us closer to mass-market fuel cell adoption.

The international buzz is real. Teams from Germany, Japan, and the U.S. are meeting with W. Jin et al., exploring co-development projects and licensing deals. Major automakers and energy giants have their ears to the ground, ready to slip this coating into next-gen vehicle stacks and industrial electrolyzers alike. When academia, industry, and government pull in the same direction, breakthroughs accelerate.

Scaling up is the next frontier. If we can translate this room-temperature, low-energy electrodeposition method from bench to gigawatt-scale manufacturing without hiccups, we could hit a true inflection point by decade’s end. That means hydrogen-powered trains, trucks, power plants, and even early aviation fuel cell modules becoming everyday realities. It’s a classic case of materials innovation: a tiny tweak—sprinkling in some niobium—ripple effects across an entire energy ecosystem.

China’s materials scientists have laid out a clear path showing how a smart coating strategy can overcome one of the toughest challenges in hydrogen energy technology. Hitting a mere 13.8 mΩ·cm² contact resistance, with over 300 hours of stability under punishing conditions and rock-solid adhesion, the Nb-ACC process promises to make PEMFC bipolar plates significantly more durable and cost-effective. While large-scale industrial roll-out and independent tech-scale validation are still on the horizon, the world’s eyes are on this innovation. It’s more than a promising lab result—it’s a peek at what happens when materials science, electrochemistry, and policy converge to shape a cleaner, sustainable future. Let’s keep charging ahead.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.