PCB Fuel Cell Startup Bramble Energy Collapses: Lessons for Hydrogen’s Future

November 12, 2025Just as UK CleanTech looked ready for a breakthrough, news of the Bramble Energy Failure hit like a cold shower. This November, the Imperial College London/UCL spinout—celebrated for its PCB Fuel Cell design—went into administration. Launched in 2015 to leverage mass PCB supply chains and cut Hydrogen Fuel Cells costs, the venture once employed 80+ people in a 34,000 ft² Crawley hub, now standing eerily quiet.

What tripped up Bramble?

Bramble Energy sold the dream of embedding electrochemical cells into standard PCB boards to streamline stack assembly and slash capex. Early backers included BGF, which ploughed in £5 million during a 2020 Series A, alongside partnerships with MAHLE Powertrain and BOC (Linde Group). They showcased prototypes up to 50 kW, but scaling from lab demos to mass production proved tougher than expected. Despite aiming for the US DOE’s $60/kW benchmark, costs stayed well above industry norms, revenue lagged, and mounting R&D plus manufacturing bills sank the finances.

How did their PCB Fuel Cell tech really work?

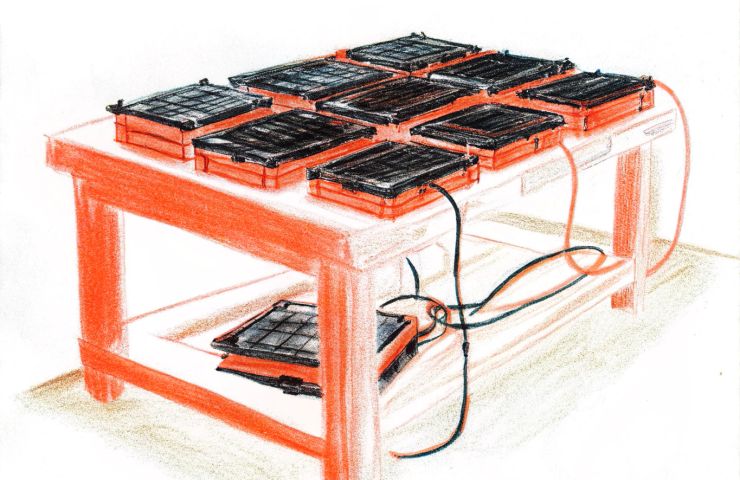

At its core, Bramble’s PCBFC™ setup leaned on off-the-shelf PCB processes to build Hydrogen Fuel Cells that promised to skip pricey metal parts and complex assembly. They touted three big advantages:

- Integration: Hydrogen channels and electrodes etched into multilayer PCB laminates.

- Scalability: Designs ready for existing PCB fabs worldwide—no new tooling needed.

- Modularity: Stack segments that could link up for outputs from a few watts to tens of kilowatts.

In practice, though, sealing layers leak-free, ensuring long-term durability and keeping boards compressed evenly proved costly hurdles—eating into the savings they’d banked on.

Who was behind the vision?

Dr. Tom Mason, Bramble’s CEO and co-founder, drew on his UCL electrochemistry PhD to chart the company’s course. On the research front, Prof. Dan Brett (UCL) and Prof. Anthony Kucernak (Imperial College) helped refine the PCBFC™ concept from lab benches to early stacks. Their belief that PCB substrates could unlock mass-market fuel cells drove rapid hiring, new test rigs and several collaborations—but couldn’t bridge the gap to a profitable production line.

Why Bramble’s fall matters to UK clean-tech

This isn’t just a local hiccup—it highlights the Clean Energy Challenges any Hydrogen Fuel Cells innovator can face:

- Cost barriers: Cutting component prices doesn’t always lower overall system costs.

- Infrastructure gaps: Even affordable stacks need a solid hydrogen network to reach customers.

- Investor caution: Clean-tech projects often require longer timelines than many VCs tolerate.

On the ground in Crawley, it’s job cuts and idle factory space. At a national level, this stumble could make backers and policy makers think twice before backing the next UK CleanTech darling.

So, what’s next?

The hydrogen sector isn’t giving up—lessons from this Bramble Energy Failure show that cost-saving must pair with strong supply chains and clear policy support. Globally, giants like Plug Power, Toyota and Bloom Energy are still charging ahead, some with deeper pockets, others testing fresh tech angles in the Hydrogen Fuel Cells arena.

Looking forward, expect future efforts to mix PCB insights with new membrane chemistries, smarter sealing methods, and tighter public-private partnerships. The hydrogen revolution isn’t over—it’s just hit a speed bump on the road to a cleaner energy future.

Erin Kilgore is a clean-energy journalist who covers sustainable tech breakthroughs around the world.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.