PowerCell Secures SEK 12M Follow-Up Order

January 5, 2026In a pretty clear sign that hydrogen fuel cells are finally taking off, PowerCell Group just secured a SEK 12 million follow-up order from a self-described “leading European aerospace research institute.” Scheduled for delivery in 2026, this deal has the Swedish hydrogen experts shipping out modular 100 kW fuel cell systems to power some high-octane testing rigs. It might sound niche, but it really drives home how serious the aviation sector is about zero-emission technology—and how PowerCell is poised to ride that wave.

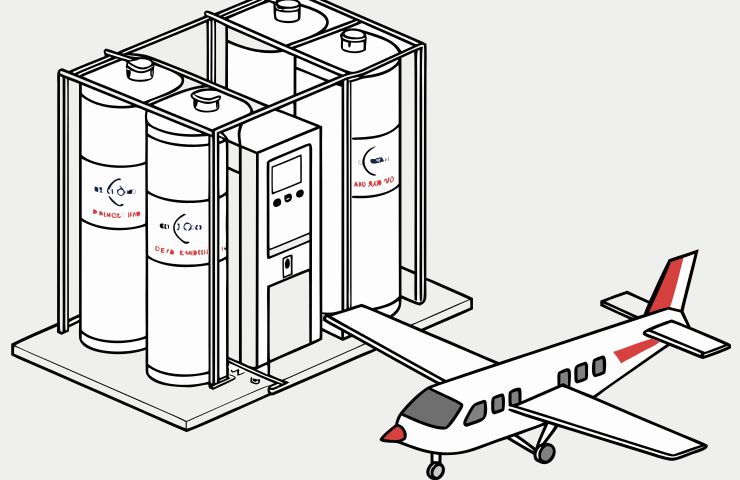

When PowerCell unveiled the new contract on December 30, 2025, it was basically an encore to the 25 MSEK order they snagged in 2021 for the same MS-100 family. Aside from the headline takeaway—SEK 12 million for a batch of 100 kW modules—it’s the setup that’s eye-opening. They’ll link them up in series, stacking voltage and current to run through startup sequences, power surges, and high-altitude thin-air scenarios. Researchers will punch in simulated flight profiles, logging performance curves and reliability data that’ll be gold for fine-tuning fuel cell technology under real-world stresses.

Technical Insight

The MS-100 is no slouch—it’s a 100 kW proton exchange membrane (PEM) system designed to be plug-and-play. Each module weighs just over 100 kg and can be bolted together for multi-megawatt setups. By converting hydrogen fuel cells into electricity (and a bit of water vapor), it shows how zero-emission power can be both powerful and compact. It’s that balance of punch and portability that makes it a hot candidate for aerospace, marine applications, and heavy-duty transport.

Driving Strategy and Partnerships

With airlines and regulators racing to hit net-zero targets, hydrogen fuel cells aren’t just a shiny idea—they’re a real contender alongside batteries and jet fuels. For PowerCell, aviation is a strategic sweet spot where their PEM proficiency can outshine the rest. They’ve already teamed up with ZeroAvia since 2021, flying low-temp PEM stacks in demonstrator planes, and last year they signed an MOU to push high-temp stacks past 2.5 kW/kg for 40–80 seat aircraft.

Now, this SEK 12 million repeat gig plugs straight into EU-backed initiatives like the Clean Aviation Joint Undertaking, which funnels billions into R&D through 2030 to advance hydrogen storage, fuel cell integration, and certification pathways at scale. By feeding hardware to the top research labs, PowerCell gets front-row seats to innovations that eventually head to aircraft OEMs and Tier-1 system integrators tinkering with hydrogen-electric powertrains for commuter jets.

Landing another order isn’t just good for the bottom line—it’s fuel for investor confidence and a lever to boost R&D budgets. As the sustainable energy debate heats up, having hard data from flight-like tests can sway policy toward beefing up hydrogen infrastructure and draw even more private and public capital.

About PowerCell Group

Born in 2009 as a Volvo Group spin-off, PowerCell Group calls Gothenburg home. They’ve carved out a niche building PEM stacks and full turnkey fuel cell technology systems that produce electricity and heat, emitting nothing but water. Beyond aerospace, they’ve got backup power solutions, marine hybrid drives, and powertrains for heavy vehicles on deck—all with an eye on high energy density and durability.

These days PowerCell runs labs in Sweden and Germany that focus on system integration and high-pressure hydrogen setups. Their R&D spend has been creeping up, mirroring a surge in interest around clean aviation and industrial decarbonization. With patents covering membrane chemistry and balance-of-plant designs, they’re not just building test rigs—they’re laying the groundwork for real-world rollouts.

Historical Context

PowerCell’s aerospace adventure kicked off in 2021 with that first 25 MSEK MS-100 stack order from the same mystery institute. That early contract funded the initial hydrogen-electric drivetrain tests and set the stage for fast follow-ups. Meanwhile, the ZeroAvia collaboration has been humming since pre-2024, starting with 20-seat demonstrators and then expanding under the 2024 MOU for high-temp stacks aiming at larger regional aircraft. Each repeat order is a vote of confidence that builds momentum.

Broader Industry Impact

- Aviation Decarbonization: High-power PEM systems are crucial for slashing CO₂ on regional hops, turning in-flight emissions into a relic of the jet age.

- Tech Spillover: Breakthroughs in stacking and cooling for aircraft arrays feed into marine hybrids and heavy-truck powerpacks, spreading the benefits of advanced fuel cell technology.

- Certification Momentum: Real-world data from these tests feeds bodies like EASA, smoothing the path for zero-emission technology to go from lab benches to service manuals.

- Infrastructure Push: Proven, reliable fuel cell modules justify upfront bets on airport hydrogen hubs and refueling chains—the backbone of future hydrogen storage networks.

- Investor Confidence: Follow-up contracts of this scale strengthen the European hydrogen ecosystem—from catalyst creators to balance-of-plant specialists—boosting the flow of capital toward sustainable energy solutions.

Of course, hurdles still lurk—hydrogen compression, storage weight penalties, and fuselage integration aren’t trivial. Every successful simulation chips away at these roadblocks, and the treasure trove of data will keep engineering teams on the right track toward commercially viable, zero-emission aviation.

Looking Ahead

The stakes are sky-high: developers need fuel cells that can handle takeoff surges, thin-air climbs, and strict weight budgets. PowerCell is hedging its bets with both low-temp and high-temp PEM stacks, covering multiple performance profiles.

In the short term, all eyes are on efficiency curves, startup times, and cycle durability under flight-like conditions. Airlines expect throttle response and rock-solid reliability on par with gas turbines—no small feat. If PowerCell hits these marks, modular MS-100 arrays could be humming under the wings of 70-seat jets within a decade.

Longer term, as green hydrogen production ramps up—think renewable-powered electrolysers—the economics of airport refueling and hydrogen hubs will only get clearer. The manufacturers that rack up pilot hours and real-world operating data now will enjoy a head start when the hydrogen highway goes mainstream.

That said, battery-electric solutions are also charging ahead, especially on shorter hops. The showdown between batteries and fuel cells will shape which tech takes off first, but there’s room for both in a low-carbon future. For now, this follow-up order cements PowerCell as a prime mover ready to power tomorrow’s green jets.

With regulators tightening emissions rules and airlines hunting for credible zero-emission technology, these 100 kW PEM modules aren’t just lab curiosities—they’re the scouts on the frontline of a sustainable energy revolution in aviation. Will hydrogen fuel cells clear the final hurdles to become mainstream propulsion? Stay tuned.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.