Revolutionizing Hydrogen Fuel Cells: Korea’s New Ternary Pt3(Co,Mn)1 Catalyst Delivers 10× Performance

January 15, 2026Picture this: hydrogen fuel cells that not only undercut batteries on price but also outlast them. Sounds like something straight out of a sci-fi flick, doesn’t it? But that’s exactly where a team at Korea University is heading. Led by Professor Kwangryul Lee, they’ve whipped up a Pt3(Co,Mn)1 intermetallic nanocatalyst that leverages tiny interfacial oxygen vacancies—think microscopic gaps at the oxide-catalyst boundary—to line up atoms in a flawless lattice. The result? Over ten times the mass activity of your run-of-the-mill Pt/C catalysts and more than 96% performance retention after a brutal 150,000-cycle durability test. It’s a breakthrough that could seriously shake up the economics of fuel cell technology for cars, grid storage, and beyond.

From NASA Roots to South Korea’s Innovation Drive

It all started back in the 1830s, but the real glow-up for fuel cell technology came when NASA strapped them to spacecraft in the 1960s. Even though they ran like champs in orbit, getting them on land was a different story—platinum catalysts are pricey, and over time those particles clump or dissolve, making automakers and power companies wince. Fast-forward to today, and South Korea has put hydrogen front and center in its sustainable energy playbook, pouring billions into roadmaps, subsidies, and research hubs. Places like KIST have already dazzled with Pt–Ni catalysts, and universities are racing to hit the U.S. Department of Energy’s benchmarks. From government grants that ease the pain of buying electrolyzers to hydrogen bus pilots rolling through Seoul, the buzz is real. This push isn’t just about cleaner cars—it’s a cornerstone of industrial decarbonization and beefing up our hydrogen infrastructure. In a scene like this, a game-changing material like Pt3(Co,Mn)1 doesn’t just turn heads—it answers the market’s every question.

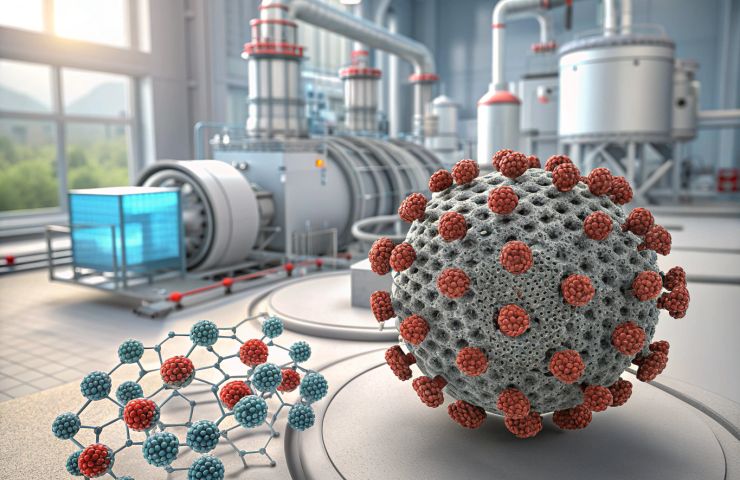

Atomic Precision: Crafting the Pt3(Co,Mn)1 Architecture

Here’s the real magic: the team fine-tuned atomic placement by playing with oxygen vacancies. They mixed platinum, cobalt, and manganese precursors on an oxide support, then fired them up under reducing conditions to coax atoms into a neat intermetallic phase. Think of those vacancies as tiny architects making sure every platinum atom lands in just the right spot, setting the stage for a faster oxygen reduction reaction (ORR). And since ORR at the cathode is the usual bottleneck for fuel cell technology, getting this right is a big deal. Plus, that ordered lattice dramatically cuts down on metal atom migration and dissolution, so you get rock-solid durability under the heavy cycling conditions you see in automotive use.

Advanced tools like TEM and XRD confirmed that beautiful intermetallic structure, while STEM images revealed crystal-clear atomic ordering. Spectroscopy even showed a shift in the platinum d-band center, fine-tuning how oxygen intermediates bind and dropping the ORR activation barrier. In everyday terms, the catalyst’s electronic makeup is dialed in at the atomic level.

And there’s more: those engineered vacancies don’t just sculpt the lattice—they act like express lanes for oxygen species, boosting mass transport. This winning combo of structural order and vacancy-driven diffusion means reactants hit active sites faster, and the whole framework resists collapsing after tons of cycles. Talk about solving two of the biggest headaches in conventional catalysts.

Performance that Speaks Volumes

I know numbers can feel dry, but stick with me—these stats are wild. In rotating disk electrode (RDE) trials at room temp with an O2-saturated 0.1 M HClO4 electrolyte, the Pt3(Co,Mn)1 catalyst clocked 3.5 A/mg Pt at 0.9 V vs. RHE—over ten times what you get from standard Pt/C, which usually limps in below 0.3 A/mg Pt. The half-wave potential also jumped by more than 50 mV, signaling a serious boost in ORR kinetics. These aren’t just bragging rights; they crush the U.S. Department of Energy’s 2025 goal of 0.44 A/mg Pt and a 35 mV Tafel slope.

Then there’s durability. We ran 150,000 potential cycles from 0.6 to 1.0 V to mimic the ups and downs of real automotive duty. Post-test RDE and MEA checks showed performance hanging above 96%, compared to the 40–60% drops you typically see in top-tier Pt/C catalysts after just 30,000 cycles. And when we threw it into a full-cell MEA setup, power densities hit 1.2 W/cm2 at 0.6 V—right up there with premium commercial systems. In plain speak, this is the durability-meets-performance unicorn we’ve all been hunting for.

What It Means for the Hydrogen Economy

Small improvements at the atomic level can trigger big waves across the hydrogen economy. Using fewer grams of platinum per kilowatt means lower manufacturing costs, and that translates directly into cheaper fuel cell electric vehicles (FCEVs). Stationary power setups—think backup generators or neighborhood microgrids—get a lift too. With the world charging towards sustainable energy and industrial decarbonization, an affordable, long-lasting catalyst like this is exactly the shot in the arm the sector needs.

Of course, we still have mountains to climb with large-scale hydrogen production, storage, and distribution. This tweak doesn’t solve every puzzle in fuel cell technology, but chipping away at a major hurdle—making fuel cells both cost-effective and battle-tested—forges a clearer path toward robust hydrogen infrastructure.

A Collaborative Triumph

This wasn’t a solo act—it took a whole squad. Korea University, KIST under Dr. Seongjong Yoo, and Sungkyunkwan University’s materials team led by Professor Sangwook Lee all pitched in. Funding from the Korean Ministry of Science and ICT’s Leader Research program, KIST’s own resources, and the H2Gather initiative made it possible to swap ideas and gear on the fly. What might normally drag out over years got knocked out in months thanks to this multi-institutional hustle. And by publishing the details in Advanced Materials this month, they’ve handed the global community everything needed to reproduce and build on their work.

Looking to the Horizon

Looking ahead, the big challenge is scaling this from milligrams in the lab to kilograms for commercial stacks. Pilot-scale production has to lock in those delicate oxygen vacancies—meaning fine-tuned reduction environments and precise temperature control. Industrial partners are already eyeing ways to retrofit their roll-to-roll coating lines to handle Pt3(Co,Mn)1 inks. At the same time, regulators in Europe and Asia are updating fuel cell certification standards to include next-gen intermetallic catalysts.

They’re also hunting for other metals—nickel, iron, even a rare earth—to see if the same ordering and vacancy trick works. Recycling plans are in the works too, aiming to pull cobalt and manganese back out with minimal energy input. If everything pans out, we could see FCEVs and backup power units rocking Pt3(Co,Mn)1 in the next five years, bringing a truly robust hydrogen infrastructure into view.

Breakthroughs like these light a fire under broader change. We’re not popping champagne on decarbonization just yet, but with fuel cell technology improvements—from these Pt3(Co,Mn)1 catalysts to smarter electrolyzers—it’s easy to see the pieces falling into place. If you’ve been keeping tabs on the hydrogen world, consider this a turning point: a future of cheap, long-lasting clean energy built on atomic-scale wizardry is almost here.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.