Seawater Hydrogen Production with MXene Catalyst

September 19, 2025On July 21, 2025, Korea Institute of Materials Science (KIMS) dropped the news about a trailblazing initiative spearheaded by Dr. Juchan Yang at their Hydrogen & Battery Materials Center. At its heart, the project aims to rewrite the rules of seawater electrolysis for hydrogen production, crafting a rugged electrode catalyst that laughs in the face of chloride-induced corrosion and still delivers top-tier output. Laid out in ACS Nano, this venture fits like a glove with South Korea’s National Hydrogen Strategy and the global drumbeat for Green Hydrogen. With over 51 million people and coastlines that stretch for days, South Korea is perfectly poised to steer the future of Seawater Hydrogen Production.

A Long-Standing Challenge

For years, scientists have been butting heads with a pesky culprit: chloride ions. In your average electrolysis setup, these little troublemakers corrode electrode surfaces and tank efficiency faster than you can say “rust.” Sure, skipping straight to freshwater helped beat back the issue, but filtering out salts jack-knocks the cost and adds a bureaucracy of complexity. Early flirtations with two-dimensional MXene materials showed promise—until they oxidized or fractured under real-world stress. Cracking this code has felt like the final piece in the puzzle to make seawater hydrogen production both cost-effective and industrial-strength.

Solving Real-World Problems with Simple but Powerful Technology

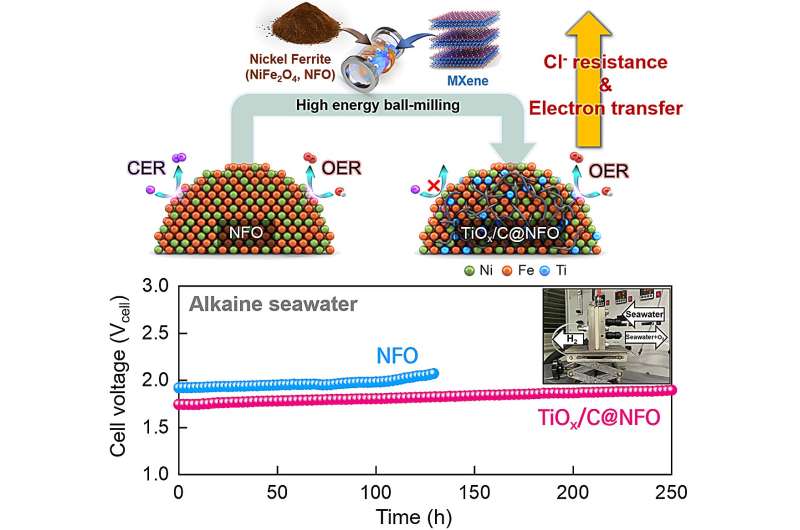

The idea is refreshingly straightforward: take a sheet of MXene, purposely oxidize it to beef up its stability, then put it through high-energy ball milling with nickel ferrite (NiFe₂O₄). The outcome? A MXene-NiFe₂O₄ Composite that wraps each electrode in a nano-fortress. This nano-fortress delivers outstanding Chloride Corrosion Resistance, kicking chloride ions to the curb and fending off corrosion. “We were after a barely-there coating that’s almost indestructible in brutal seawater,” says Dr. Yang. It’s a direct hit on electrode degradation, making long-haul seawater electrolysis not just possible, but practical.

Impressive Performance Gains

In lab trials, this new catalyst shot current densities nearly five times higher than conventional electrodes in seawater and lasted twice as long under nonstop operation. And we’re not talking petri-dish wizardry—these results stood up in a full-fledged electrolysis unit cell, suggesting scale-up isn’t just a pipe dream. The bottom line? Faster hydrogen output and fewer maintenance pit stops, a real game-changer when you’re talking industrial-scale viability.

Right in Step with Global Decarbonization Goals

Dialing in Green Hydrogen from seawater is a slam dunk for industries and coastal communities eager to shrink their carbon footprints without draining freshwater reserves. Hook this catalyst up to offshore wind farms, solar plants, or tidal setups, and you’ve got a zero-emission hydrogen hub that doesn’t siphon off drinking water. It’s tailor-made for global net-zero targets by mid-century and a lifeline for regions battling water scarcity.

Made in South Korea, Made for South Korea’s Future

This breakthrough is pure KIMS Research muscle—backed by government investment and powered by a tight-knit academic-industrial network. By keeping R&D and manufacturing local, the team can fast-track deployment and keep costs lean. Homegrown firms can license the tech, sparking jobs in high-tech manufacturing and clean-energy services. It’s a win-win: innovation feeding the economy while locking down a domestic source of Green Hydrogen.

Global Collaboration Potential

While the project is rooted in South Korea, its appeal is truly global. Whether it’s Australia, the Middle East, or island nations flush with seawater, the MXene-NiFe₂O₄ Composite offers a ready-made blueprint for jumpstarting local hydrogen economies. KIMS is all in for joint research, licensing deals, and training programs for international partners. By sharing its findings in ACS Nano, the institute is handing the world a chance to refine and roll out this solution at scale.

Scaling Up for Real-World Impact

Lab success is great, but commercial reality is the real test. That’s why KIMS is already fine-tuning the synthesis for bigger electrode formats and tighter cost control. Early indicators show the ball-milling process slots easily into mass-production lines without sacrificing performance. At the same time, a cradle-to-grave lifecycle analysis is underway to ensure material sourcing, manufacturing, and recycling minimize environmental impact.

Next Steps and Outlook

Next up: pilot installations at coastal renewable energy sites where this catalyst will run nonstop for months, proving its mettle. KIMS is hashing out partnerships with industry and public agencies to integrate the tech into existing hydrogen infrastructure. Sure, they’ll need more field data and a sharper cost breakdown, but the blueprint laid out in ACS Nano looks solid. Large-scale Seawater Hydrogen Production could soon cross from concept to reality.

At the end of the day, the work led by Dr. Juchan Yang at KIMS feels like a giant leap toward tapping the ocean’s vast energy potential. By solving the Chloride Corrosion Resistance puzzle and delivering genuine performance gains, this breakthrough could power coastal industries and remote communities alike. As we push toward a cleaner future, innovations like the MXene-NiFe₂O₄ Composite remind us that mixing smart materials with local expertise can turn bold ideas into world-changing technologies.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

A break through initiative to producing hydrogen from Sea water using MXene-NiFe₂O₄ Composite.

It is a giant leap toward tapping the ocean’s vast energy potential. .Congratulations to theteam and the Institute for this service to humanity.

Although the project is rooted in South Korea, its appeal is truly global. Whether it’s Australia, the Middle East, or island nations flush with seawater, the MXene-NiFe₂O₄ Composite offers a ready-made blueprint for jump starting local hydrogen economies.

Dr Himmat Singh