TÜV Verband’s Leaflet 1276 Details Metal Damage Mechanisms

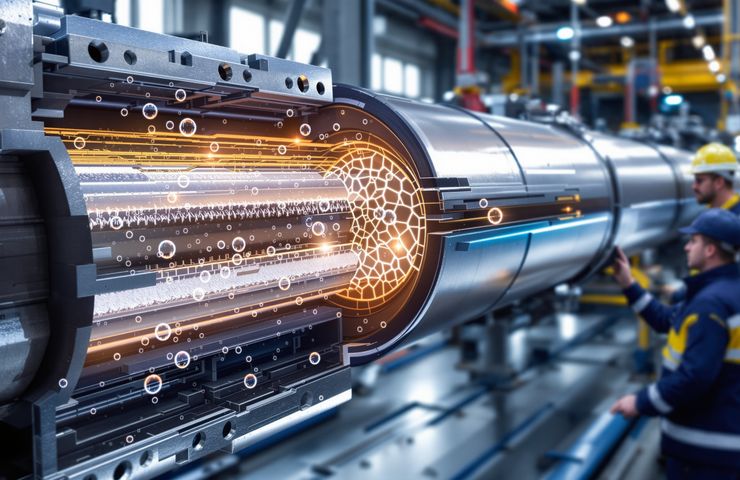

October 27, 2025TÜV Verband has rolled out its latest guide: leaflet 1276. It’s not your typical dry report—it digs into how gaseous hydrogen interacts with structural metals. As hydrogen infrastructure expands—from high-pressure pipelines and storage vessels to entire transport and distribution networks—knowing where materials can fail is more important than ever. This leaflet breaks down the science of hydrogen-induced damage and, more importantly, delivers practical prevention tactics and inspection routines to protect people, equipment, and the environment.

Key Takeaways

- Damage Mechanisms: How hydrogen embrittlement, cracking, and blistering show up in steels and alloys.

- Preventive Strategies: Smart material choices, surface coatings, and pressure/temperature tricks to keep trouble at bay.

- Inspection Protocols: When to test, which non-destructive methods to use, and how to document defects effectively.

- Industry Alignment: Pushing for unified hydrogen infrastructure and hydrogen storage standards across Germany and Europe.

Understanding Metal Degradation

Ever wonder why metals crack or blister when hydrogen’s in the mix? It boils down to tiny hydrogen atoms sneaking into the metal lattice under pressure. They collect around stress points—like grain boundaries or weld seams—and recombine into H₂ pockets. That internal pressure then triggers micro-cracks or blisters from the inside out. Leaflet 1276 sorts these issues into hydrogen embrittlement, hydrogen-induced cracking (HIC), and stress corrosion cracking (SCC), showing how each one chips away at ductility, toughness, and fatigue life in common steels and nickel alloys.

Categories of Embrittlement

The leaflet lays out three main culprits:

- Hydrogen Embrittlement: Metals lose their flexibility under tensile stress.

- Hydrogen-Induced Cracking (HIC): Internal cracks that don’t spread at first but eventually join forces.

- Stress Corrosion Cracking (SCC): The nasty combo of tensile stress and hydrogen-rich corrosive environments spawning surface fractures.

Preventive Measures

- Choose low-permeability alloys or add diffusion barriers—special coatings or claddings do the trick.

- Keep hydrogen partial pressure and operating temperatures in check to limit absorption.

- Apply post-weld heat treatments (like tempering) to relieve residual stresses.

- Use cathodic protection systems to curb corrosion and cut down atomic hydrogen generation at surfaces.

Inspection and Certification Protocols

- Set risk-based inspection intervals based on operating conditions and material sensitivity.

- Lean on non-destructive testing (ultrasonic, magnetic particle, radiographic) to catch early-stage defects.

- Document and analyze defect trends to power predictive maintenance schedules.

- Bring in third-party certification to ensure compliance with international hydrogen infrastructure standards.

Historic Roots and Modern Adaptation

You might not realize it, but today’s system traces back to mid-19th-century boiler inspections. Over the years, Germany’s safety framework evolved into the TÜV we know now. Leaflet 1276 carries that legacy forward, blending classic risk assessments with cutting-edge hydrogen production and sustainable energy research—turning old-school safety rules into tools for zero-emission tech.

Harmonization Across Europe

By publishing standardized guidelines, TÜV Verband is knitting together a more cohesive European approach to hydrogen storage, transport, and wider hydrogen infrastructure. That means fewer regulatory headaches, smoother cross-border pipeline projects, and a shared playbook for best practices.

Business and Strategic Impact

Companies and investors can celebrate lower insurance premiums, less downtime, and a clearer path to compliance. Solid certifications boost confidence, fast-tracking funding for green hydrogen ventures. After all, in an industry where a single pipe failure can rack up multi-million-euro losses, these guidelines are a real game-changer for industrial decarbonization.

Training and Further Resources

Leaflet 1276 comes paired with hands-on training modules and workshops led by TÜV Verband experts. They’ll help engineers and inspectors nail down test interpretations and mitigation techniques. Plus, you can dive into additional pamphlets and real-world case studies on the association’s website.

Looking Ahead

As we ramp up hydrogen adoption, expect these protocols to evolve—driven by pilot project feedback and breakthroughs in materials science. For now, leaflet 1276 stands as your go-to reference, making sure safety keeps pace with the spread of clean energy infrastructure.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.