Ultrafast 3,000°C Photothermal Process for Hydrogen Production Catalysts

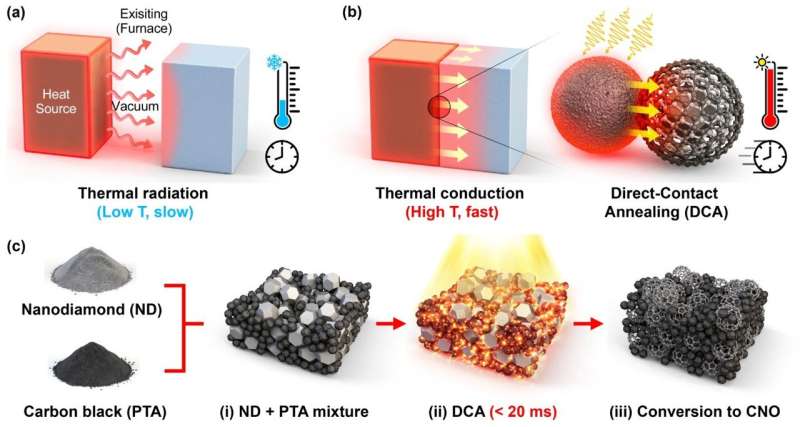

October 24, 2025In just a blink—really, 0.02 seconds—KAIST researchers have cranked temperatures to an eye-popping 3,000°C. No slow furnace here: they’ve got a custom photothermal annealing platform that slams heat onto catalysts in milliseconds. This rapid-fire trick is shaking up hydrogen production, cutting prep time from hours (or days!) to a tiny fraction, and paving the way for more efficient, greener methods.

Core Findings

Team effort alert: Professor Il-Doo Kim and Professor Sung-Yool Choi at KAIST cooked up an Ultrafast Photothermal Annealing Platform using bursts from a powerful xenon lamp. In 0.02 seconds, samples hit 3,000°C. They mix light-absorbing carbon black with nanodiamond precursors to form conductive Carbon Nanoonions (CNOs), while metal salts—platinum, cobalt or nickel—break down and lock onto the CNOs as single atoms. In the September issue of ACS Nano, they showed off consistent results across various precursors, using electron microscopy and electrochemical tests. Compared to old-school furnaces, they saw up to a sixfold jump in hydrogen evolution efficiency and slashed energy use by more than a thousandfold.

Technical Insight

Scaling up catalyst production has always been a headache. Traditional ovens demand high heat, long bake times and extra cleanup. Here’s the KAIST magic in a nutshell:

• Flash Heating: A xenon lamp zaps samples with a super-intense light pulse for just 0.02 seconds, with carbon black turning light into instant heat.

• Rapid Temperature Spike: Temperatures soar to 3,000°C in milliseconds—no waiting around for the furnace to warm up.

• One-Step Transformation: Nanodiamonds graphitize into CNOs, and metal salts split and anchor as single atoms—all in one go.

• Quick Quenching: Fast cooling stops metals from clumping, keeping them atomically dispersed.

This all-in-one maneuver cuts out separate annealing, purification and deposition, slashing both time and power demands.

Strategic Implications

Imagine chopping synthesis energy by over a thousand times—that’s a serious cut in electricity bills and CO₂ emissions for green hydrogen. Plus, a sixfold boost in evolution efficiency means fuel cells need less pricey platinum. Where old methods gulp tens of kWh per gram of catalyst, KAIST’s trick might wring it down to mere watt-hours. That’s a game-changer for local hydrogen infrastructure and could kick-start regional hubs, giving a real boost to local economies. When energy costs swing wildly across regions, this slashed power draw helps stabilize production economics and even out competitive advantages. Sure, scaling up means designing lamp arrays for even heating and nailing tough safety standards, but the upside for industrial decarbonization is massive.

Historical Context

Traditionally, making catalysts for hydrogen production has been a multi-step slog: furnace annealing at sub-1,500°C for hours, metal loading with risks of clumping, then extra tweaks. Photothermal methods teased a faster route before but never meshed rapid heating, metal loading and scale. The KAIST crew’s platform checks all those boxes, delivering a cleaner, faster, fully integrated approach.

Potential Applications

Beyond cranking out H₂, these single-atom catalysts on CNOs could shine in gas sensing—think ultra-sensitive platinum-CNO sensors spotting trace H₂. They’re also promising for environmental catalysis, like CO oxidation or CO₂ reduction. The beauty? You could decentralize catalyst production, whipping up materials on demand for various electrochemical processes, supercharging both sustainable energy and hydrogen infrastructure. Plus, imagine them in fuel cell vehicles or backup power systems in remote areas—they’d be a real game-changer.

Expert Perspective

“Our ultrafast photothermal annealing platform doesn’t just slash production time—it gives us crazy control over single-atom dispersion,” says Professor Il-Doo Kim. Co-leader Professor Sung-Yool Choi chimes in, “We’re already testing scale-up on meter-scale substrates. Early results look great, but engineering those big lamp arrays and safety systems will be the next hurdle.”

Looking Ahead

Lab wins are awesome, but making this fly commercially calls for serious engineering: high-power lamp rigs, uniform heating over big surfaces, and beefed-up safety for gigawatt flashes. And let’s not forget regulatory hurdles and certification testing—those are huge too. If they pull it off, KAIST’s method could rewrite the economics of hydrogen production, cutting back precious metal needs and fast-tracking the hydrogen economy. We’ll be watching how it settles into real-world factories.

In the push for a cleaner planet, innovations that shrink energy use, slash catalyst costs and speed up manufacturing are the unsung heroes. KAIST’s lightning-fast photothermal approach could be a major win for industrial decarbonization, sustainable energy and the future of hydrogen production.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.

With over 15 years of reporting hydrogen news, we are your premier source for the latest updates and insights in hydrogen and renewable energy.